Extrusion forming manufacturing method for inner race of integral type titanium alloy self-lubricating spherical plain bearing

A kind of joint bearing and manufacturing method technology, which is applied to manufacturing tools, forging/pressing/hammering machinery, metal processing equipment, etc. problems, to meet the needs of manufacturing technology, high reliability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

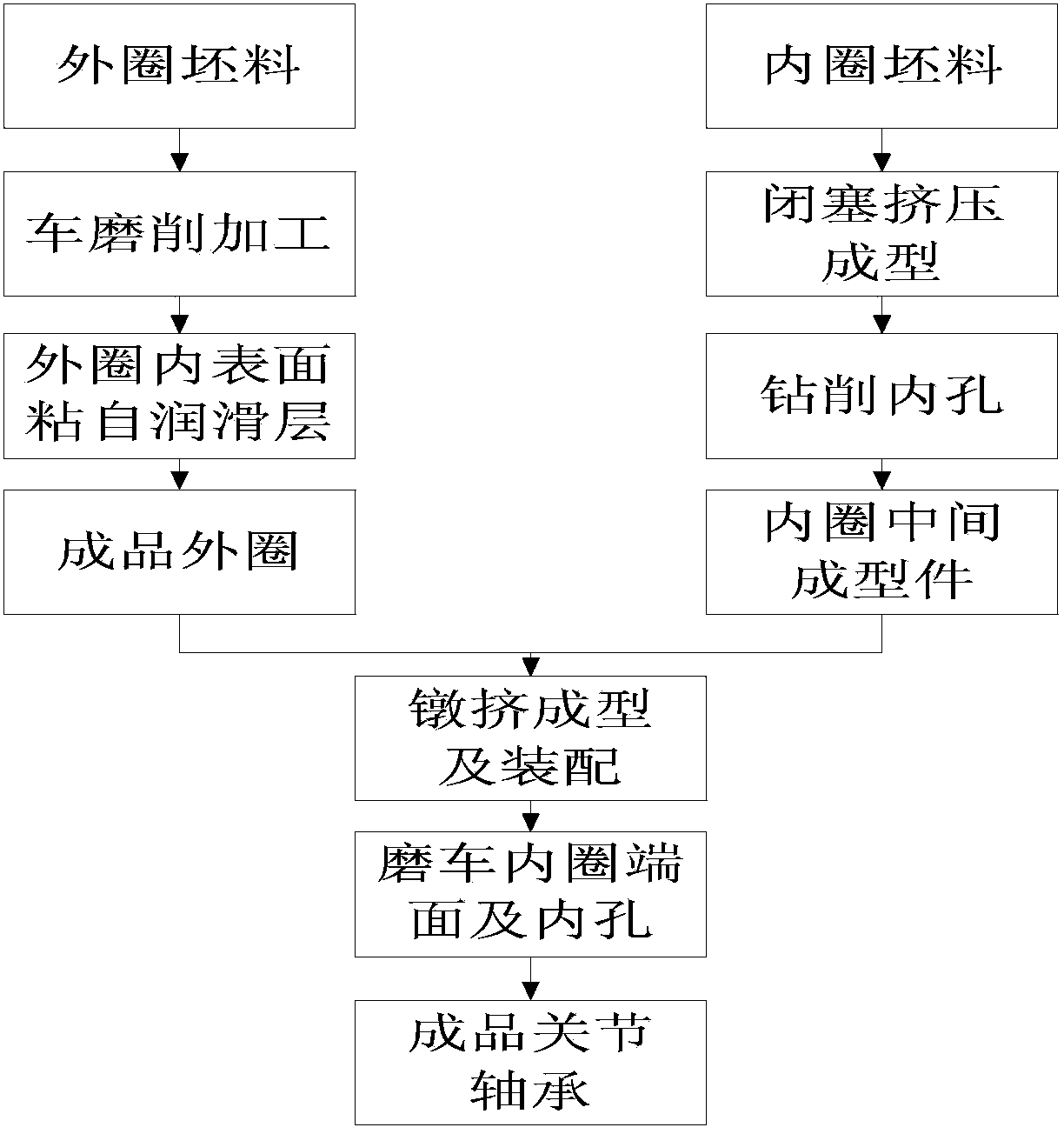

[0023] see Figure 1-7 , the integral titanium alloy self-lubricating joint bearing inner ring extrusion molding manufacturing method of the present invention comprises the following steps:

[0024] In the first step, the titanium alloy outer ring of the joint bearing is machined according to the requirements, and the self-lubricating layer is adhered to the inner surface of the outer ring to form the finished bearing outer ring 20;

[0025] In the second step, the bearing inner ring blank 12 is subjected to closed extrusion molding through the closed extrusion die. The inner ring blank is blanked as a bar, and positioning holes are drilled at the bottom. The three-lobe mold 16 is composed of the three-lobe mold 16, which can slide in the dovetail groove of the backing plate 17 under it. The blank support column 18 is provided in the middle of the backing plate to extend into the lower part of the three-lobe mold, and the tail of the three-lobe mold is installed with a tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com