Switching reactor with novel coil structure

A reactor and coil technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problem of excessive voltage deviation at the tap position, exceeding the standard required value, etc., to improve the accuracy of voltage regulation and meet performance requirements , the effect of reducing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

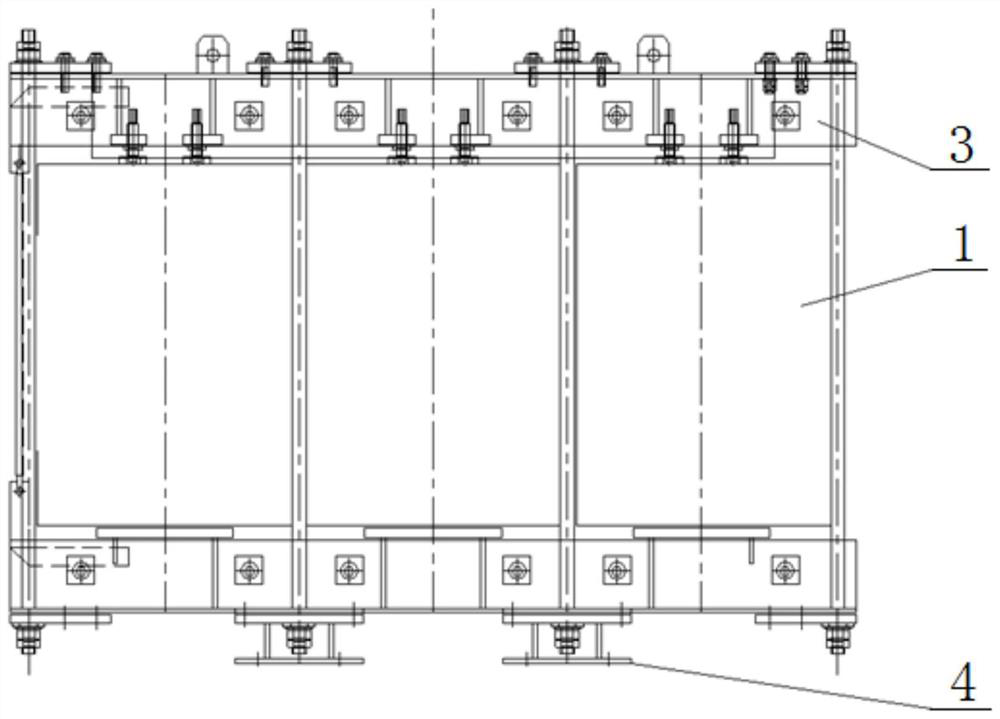

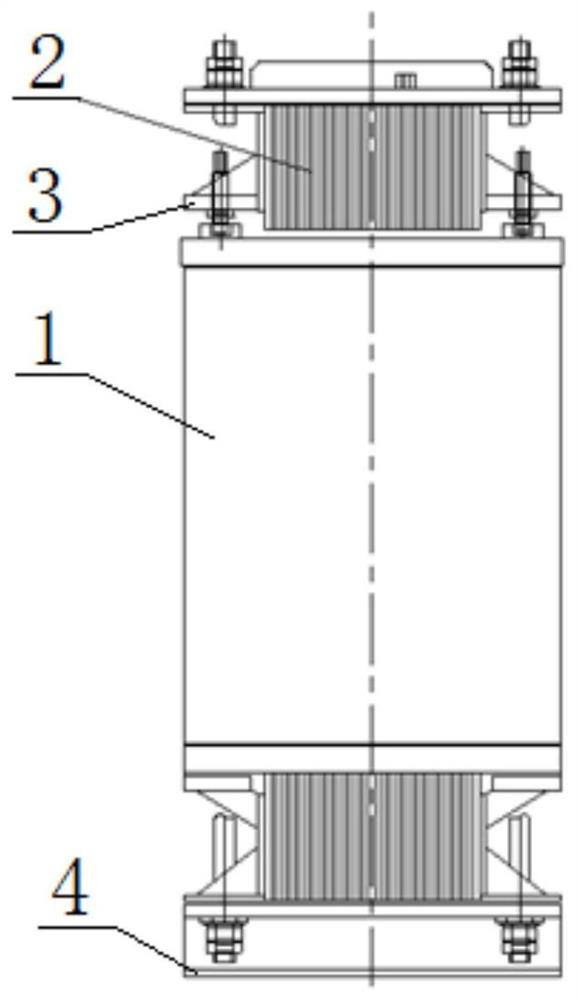

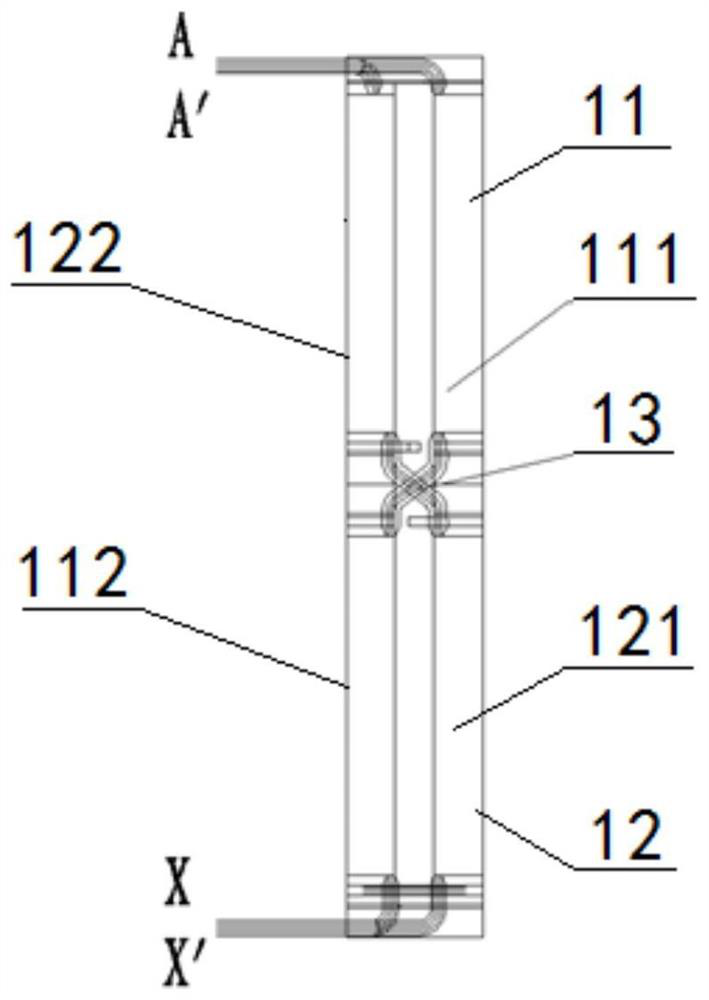

[0022] Such as Figure 1-3 As shown, a switching reactor with a novel coil structure provided by the present invention includes a double-arm coil 1, an iron core part 2 and an iron core clip 3. The iron core part 2 is a three-phase three-column structure, and each phase core A double-arm coil 1 is sleeved on the top, and the double-arm coil 1 includes a first arm coil 11 and a second arm coil 12, and the first arm coil 11 and the second arm coil 12 are wound on the core column in opposite directions to form a first The arm inner layer coil 111 and the second arm inner layer coil 121, the first arm coil 11 and the second arm coil 12 are cross-transposed at the middle position in the height of the core column and raised to the outer layer for windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com