Tilted axial array circumferential eccentric eddy current probe and method for detection of small-diameter pipes

A technology of eddy current probe and small-diameter tube, which is applied in the field of electromagnetic non-destructive testing probe, can solve the problems of high cost, low probe resolution, missed detection, etc., and achieve the effect of improving work efficiency, high detection ability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

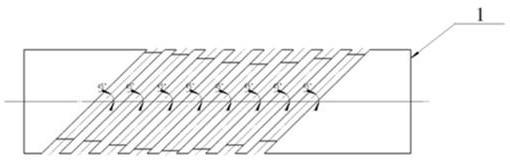

[0024] As shown in Figure 1, this embodiment is an inclined axial array circumferential eccentric eddy current probe for detection of small-diameter pipes. The enameled wire from mm to 0.1mm is wound on the skeleton 1 and spirally wound to 200 to 600 turns to form independent coils 2. The axial distance between all coils 2 is 2mm, and the axial height of the coils is 3mm.

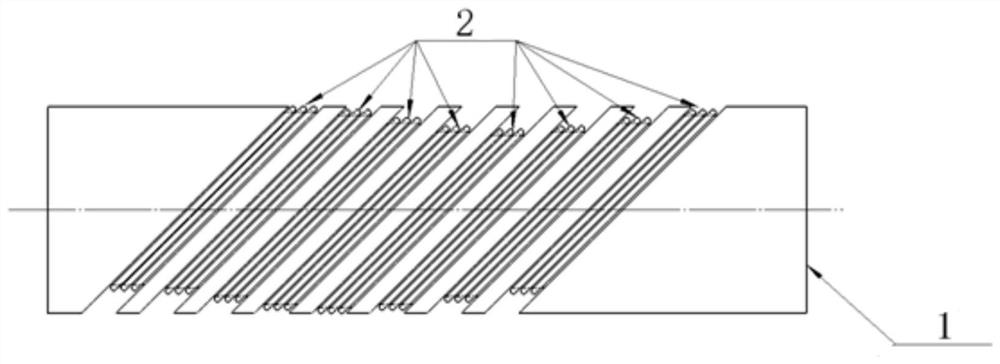

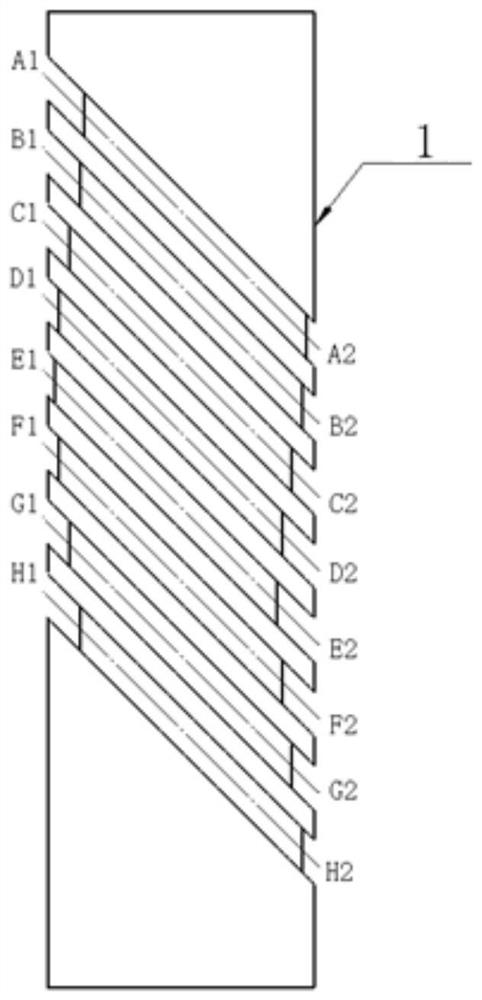

[0025] Such as Figure 2a and Figure 2b As shown, the cylindrical frame 1 of the inclined axial array circumferential eccentric eddy current probe has a groove structure for winding the coil 2, the angle between the groove section and the probe axis is 45°, and the inclination directions of all the grooves are consistent, as shown in Figure 3a As shown, set the axis of all coils 2 to have an eccentric distance of 1mm from the axis of the probe; Figure 3b , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com