All-glass heat pipe medium-temperature evacuated solar collecting pipe

An all-glass, heat-collecting tube technology, which is applied to solar collectors, solar collector safety, solar collector components, etc., can solve the problems of low-efficiency anti-freezing of heat-collecting tubes, so as to improve the effective heat gain and reduce the Adhesion, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

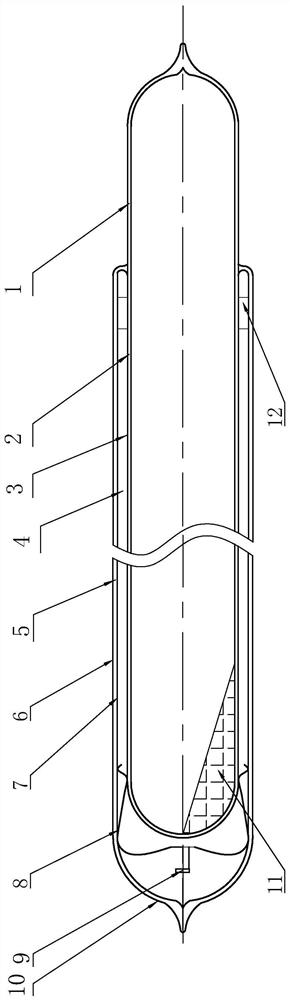

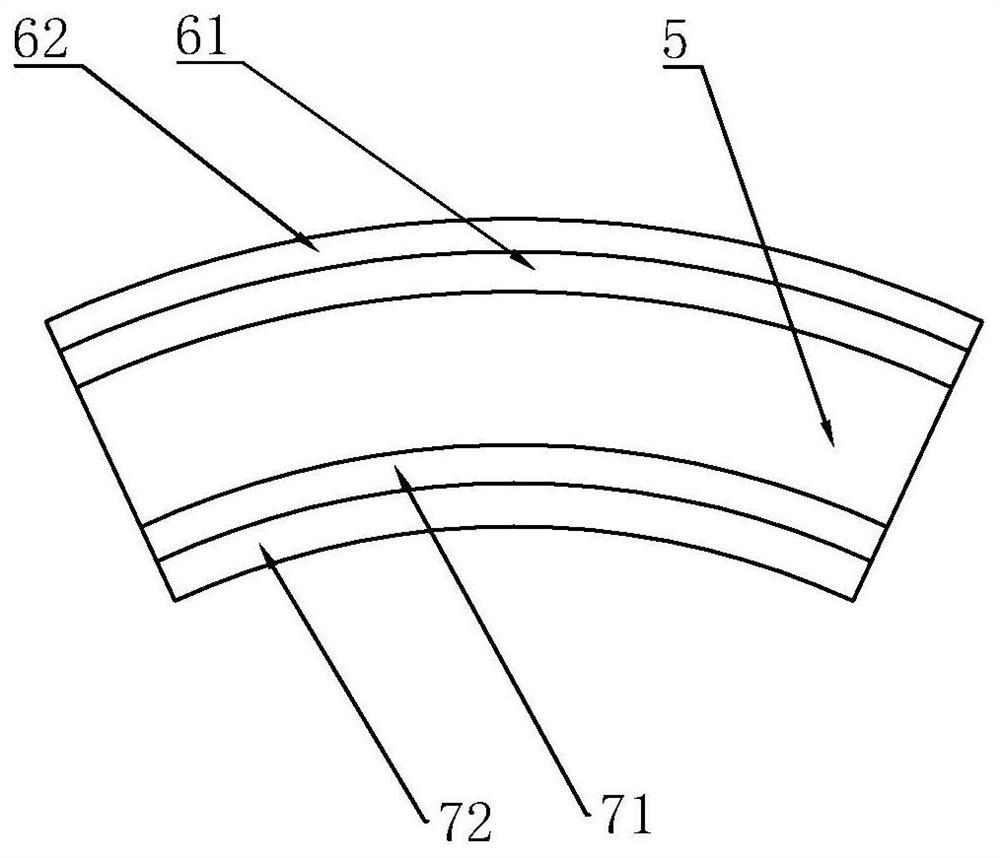

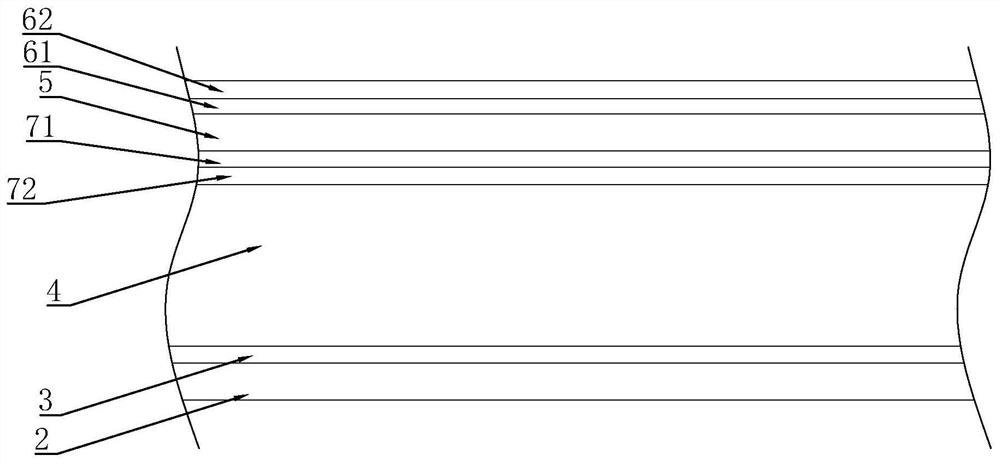

[0024] Such as figure 1 As shown, the present invention provides a kind of all-glass heat pipe medium-temperature vacuum solar heat collector, which mainly includes a cover glass tube 5, an inner glass tube 2 and a condensation section 1, wherein:

[0025] The inner glass tube 2 is located in the cover glass tube 5 and arranged coaxially with the cover glass tube 5 . The round head of the inner glass tube 2 and the round head of the cover glass tube 5 are in the same direction, and are supported and fixed by the rear support member 8 . The opening of the inner glass tube 2 is in the same direction as the opening of the cover glass tube 5, and is supported and fixed by the front support member 12;

[0026] The opening of the inner glass tube 2 and the opening of the cover glass tube 5 and the condensing section 1 realize three-tube fusion sealing butt joint (or, when the inner glass tube 2 and the condensing section 1 are integral structures, the overall structure of the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com