A vibration buffer limit device

A technology of limit device and limit hole, which is applied in the direction of non-rotational vibration suppression, brake type, mechanical equipment, etc., can solve the problems of lack of protection, buffer device can not limit and adjust, etc., and achieve large operation and maintenance space , stable vibration and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

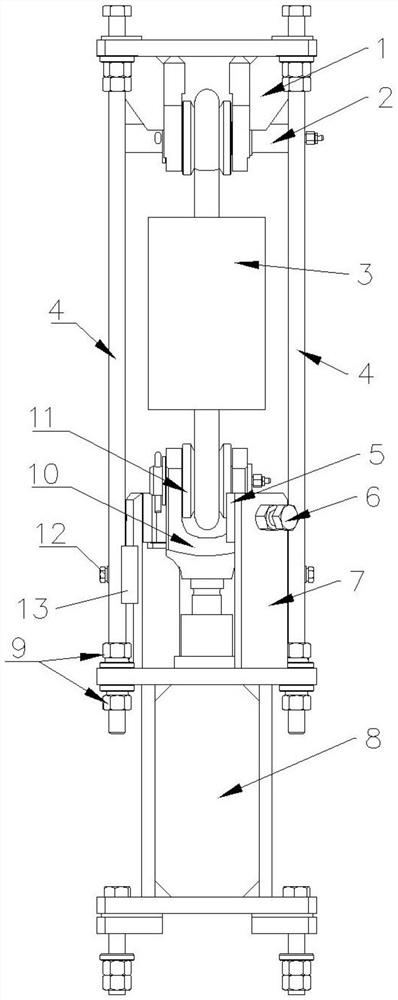

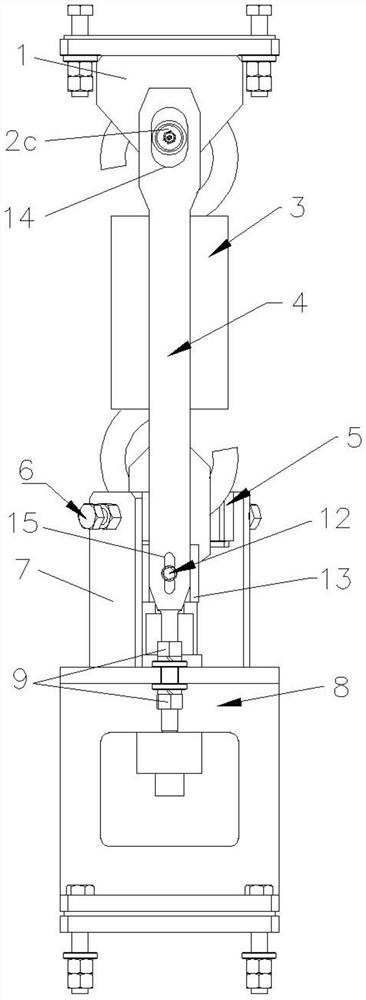

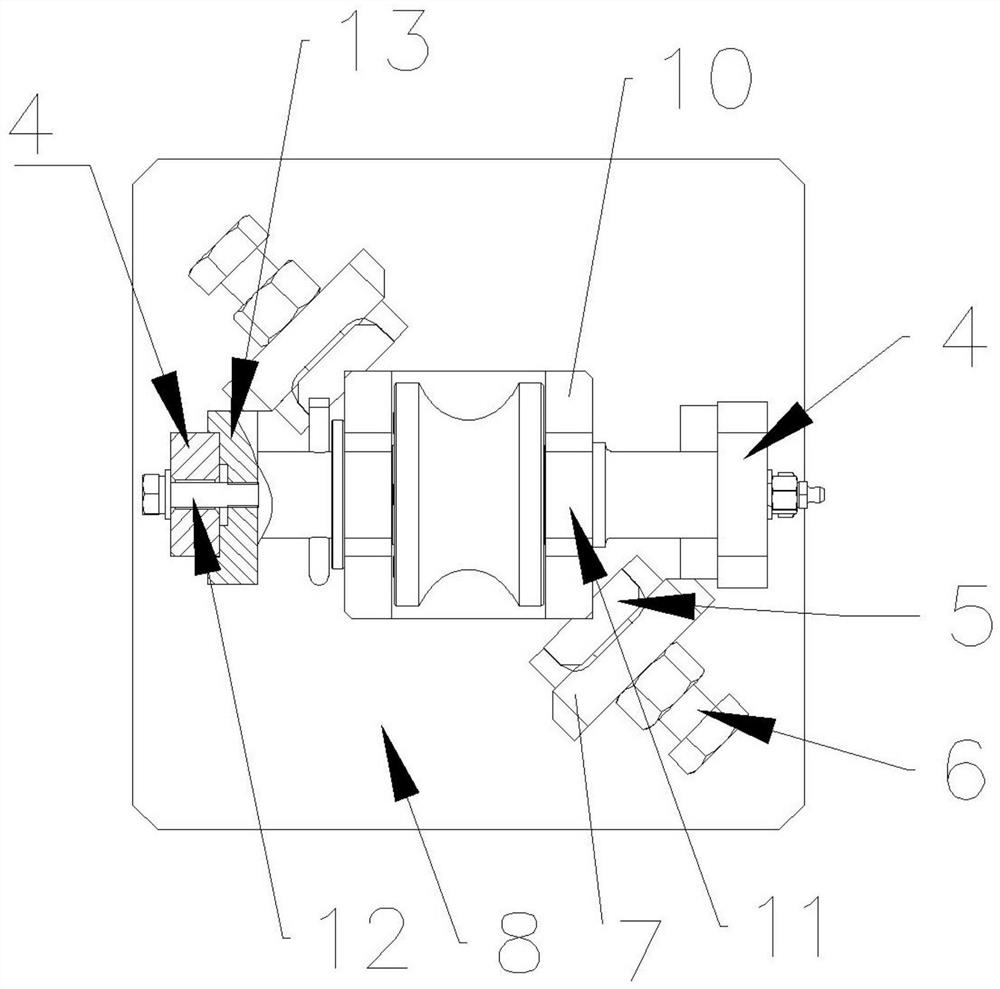

[0021] as attached Figure 1-5 As shown, a vibration buffer limit device includes a buffer connection frame 1 and a buffer connection seat 8, an upper roller assembly 2 is arranged on the lower part of the buffer connection frame 1, a roller mounting frame 10 is arranged on the upper part of the buffer connection seat 8, and a roller mounting frame 10 is arranged on The lower roller assembly 11, the two sides between the buffer connection frame 1 and the buffer connection seat 8 are respectively provided with vertical limiting plates 4, the upper part of the limiting plate 4 is provided with a vertical first limiting hole 14, and the upper roller assembly 2 has The upper roller 2a and the upper roller shaft 2c, the two ends of the upper roller shaft 2c are respectively located in the corresponding first limit hole 14 and can move up and down along the first limit hole 14, the lower roller assembly 11 has a lower roller, an upper roller 2a A bumper 3 is set between the lower ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com