An electric forklift driving wheel

A technology for electric forklifts and driving wheels, which is applied to power units, motion deposits, vehicle components, etc., can solve the problems of high maintenance costs, shortened service life of driving wheels, and easily damaged power control wires, so as to reduce the maintenance process and improve the use. Long life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

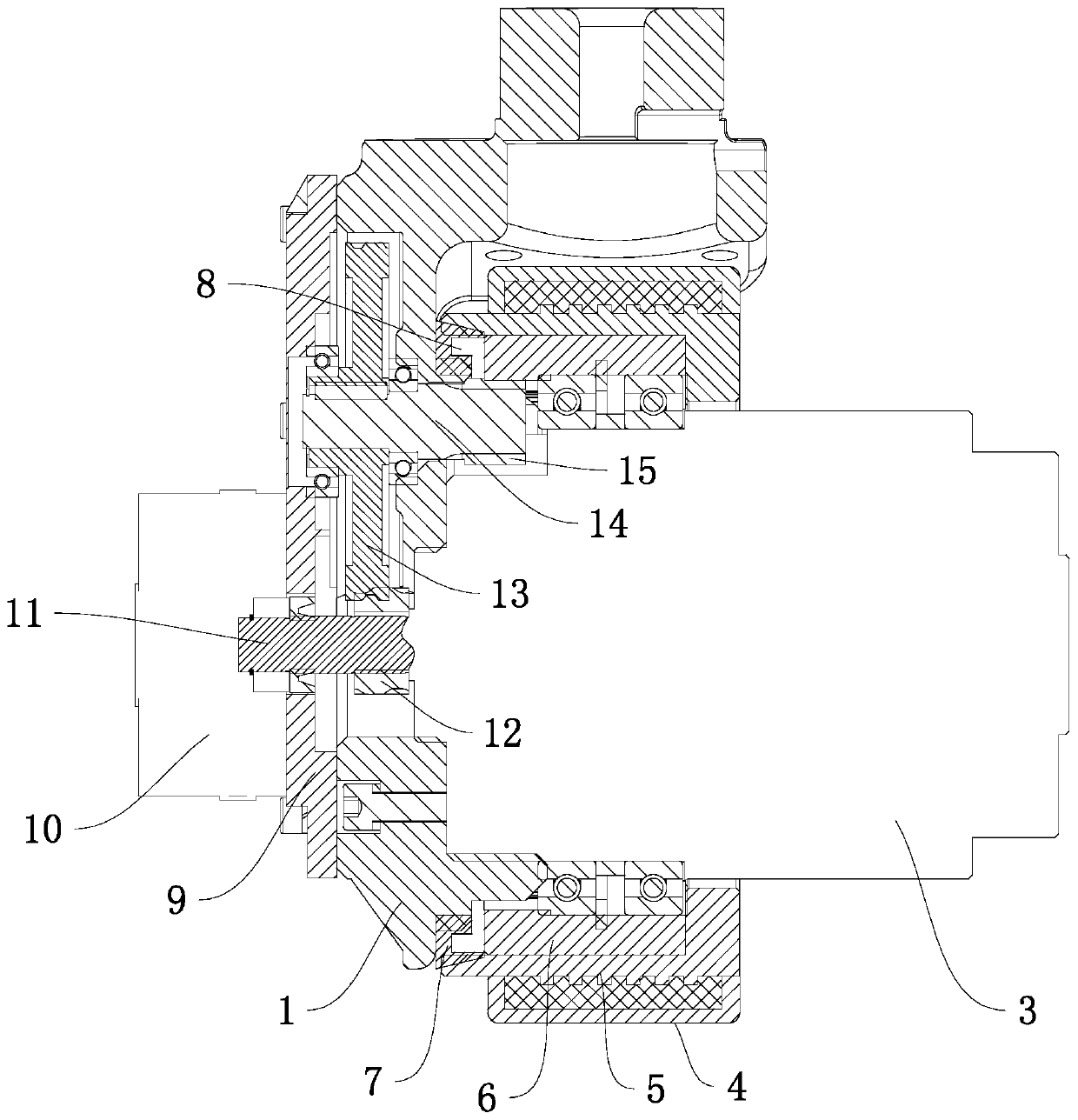

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

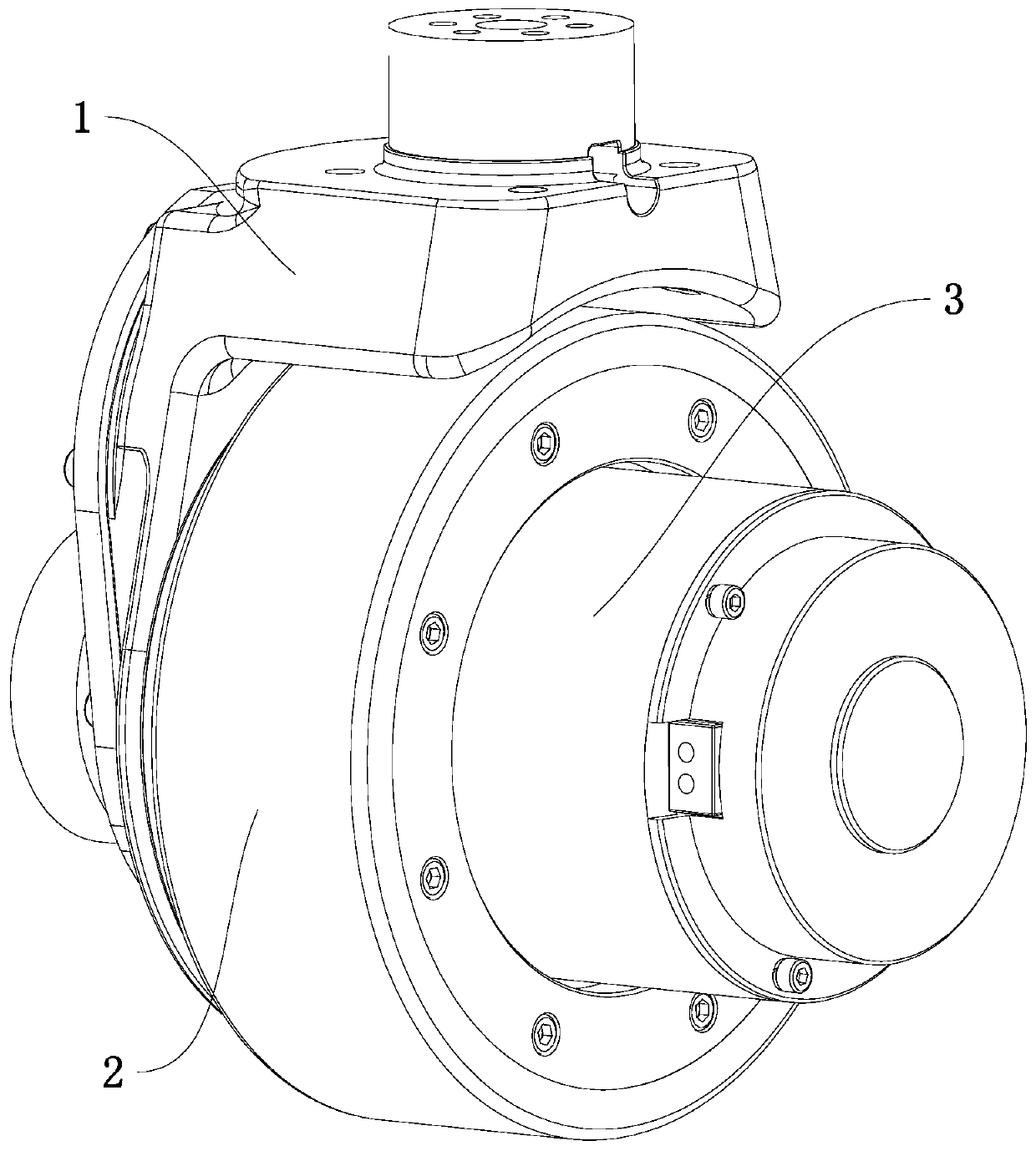

[0052] refer to Figure 1-Figure 6 Shown is a driving wheel of an electric forklift disclosed by the present invention, which includes a driving bracket 1 , a driving motor 3 mounted on the driving bracket 1 , a transmission assembly, and a rubberized wheel assembly 2 rotatably connected to the outer ring of the driving motor 3 .

[0053] The drive bracket 1 includes an integrally cast mounting portion 101 and a connecting portion vertically connected to the top of the mounting portion 101 and perpendicular to the mounting portion 101. The connecting portion includes a transverse plate 102 and a hollow connecting column 103 perpendicular to the top of the transverse plate 102. The column 103 is a cylinder with a central through hole 112. The side wall of the transverse plate 102 is provided with a threading through hole 108 communicating with the inner cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com