Heat treatment device and heat treatment method for complex contour bellows

A technology of heat treatment device and bellows, which is applied in heat treatment furnace, heat treatment equipment, heat treatment process control and other directions, can solve the problems of high manufacturing cost of copying coil, stress concentration at wave crest, uneven hardening layer, etc. Low maintenance costs and the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

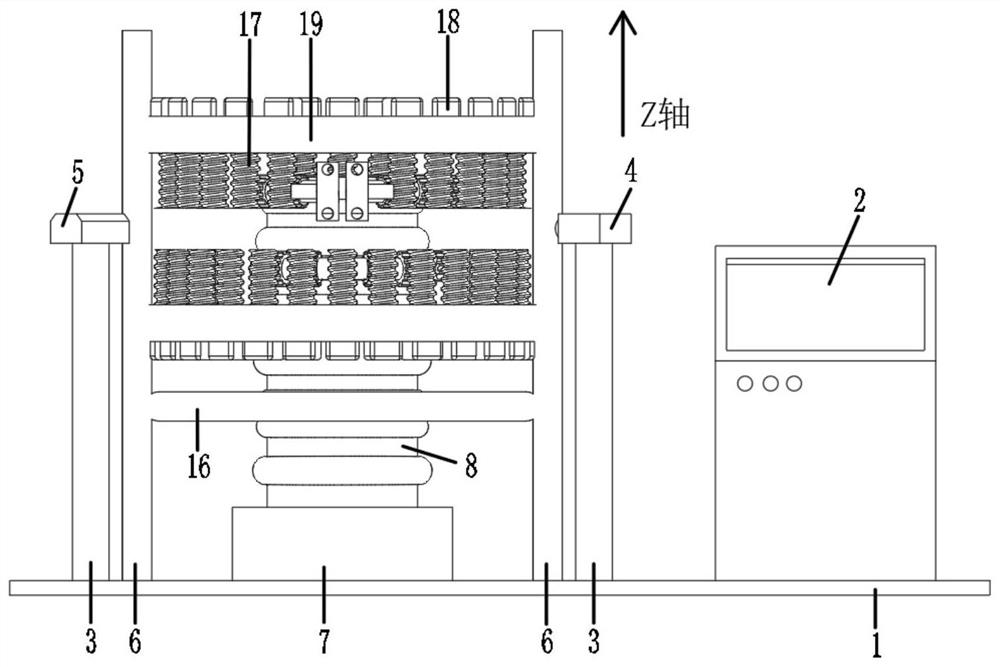

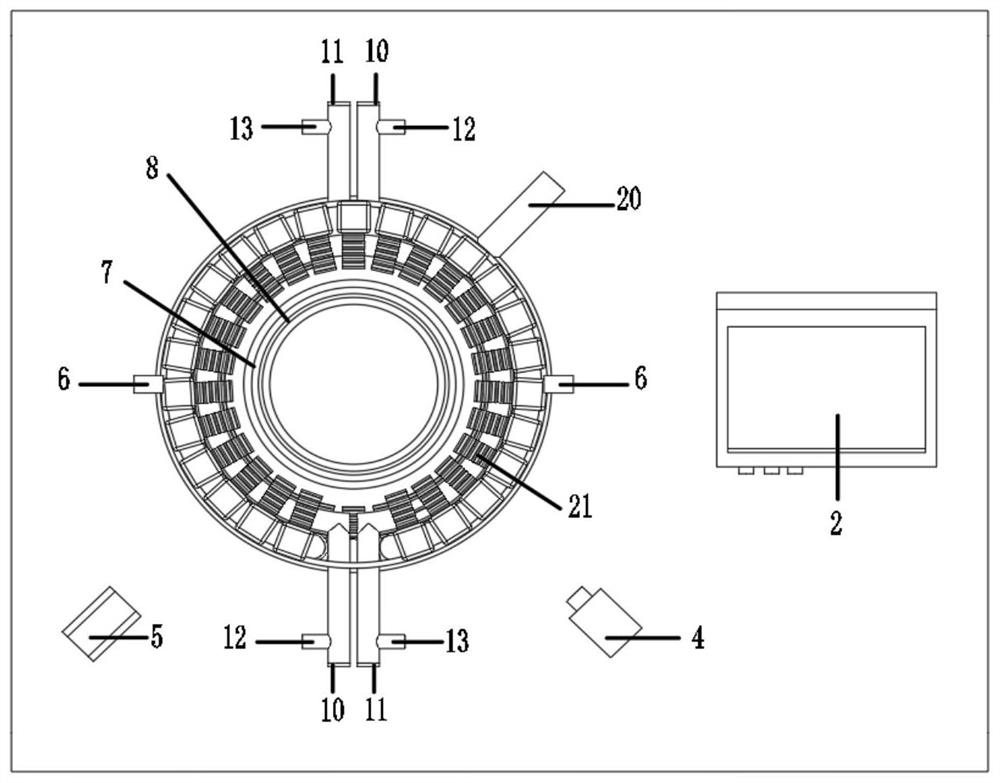

[0041] Heat treatment unit for bellows with complex contours, e.g. figure 1 As shown, it includes an induction heating mechanism, a quenching cooling unit assembly, a rotating lifting platform, a control unit assembly and a bottom plate 1, and the induction heating mechanism, a quenching cooling unit assembly, a rotating lifting platform and a bottom plate 1 are installed sequentially from top to bottom.

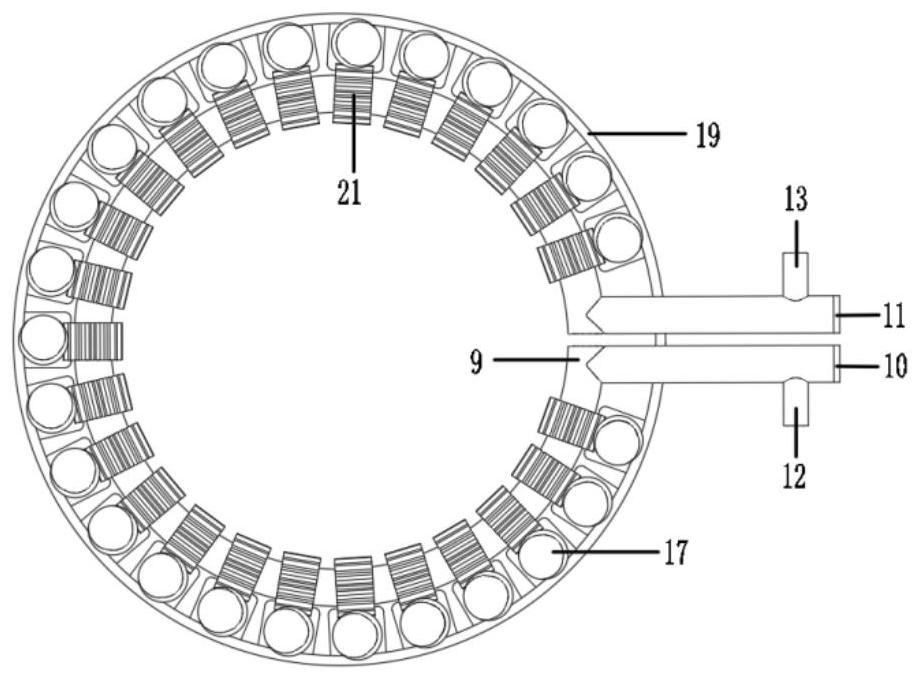

[0042] The induction heating mechanism includes a primary induction heating mechanism and a secondary induction heating mechanism, specifically including a fixed ring 19 , a servo motor 18 , a worm 17 , a circular induction coil 9 , a fixed column 6 and a male and female worm wheel 21 . The lower end of the fixed column 6 is fixedly connected to the upper surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com