Artistic coating and preparation method thereof

An art paint and mixing technology, applied in the field of paint, can solve the problems of stain resistance, poor adhesion, difficult construction, etc., and achieve the effect of maintaining basic performance, easy operation, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Further, a kind of preparation method of art paint, comprises the following steps:

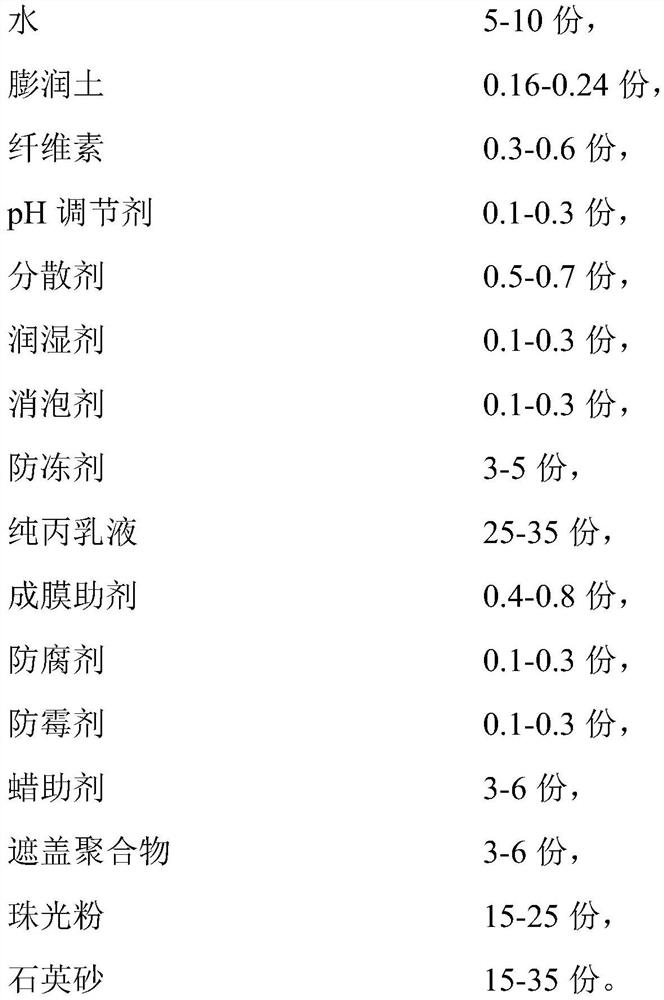

[0025] Provided according to the above art paint: water, bentonite, cellulose, pH adjuster, dispersant, wetting agent, defoamer, antifreeze, pure acrylic emulsion, film-forming aids, preservatives, antifungal agents, wax additives , covering polymer, pearlescent powder and quartz sand;

[0026] mixing the bentonite, the cellulose and the water, performing a first mixing treatment to obtain a first mixing;

[0027] The pH regulator, the dispersant, the wetting agent, the defoamer, the antifreeze, the pure acrylic emulsion, the film-forming aid, the preservative, the antifreeze The mildew agent and the wax additive are mixed with the first mixed material, and the second mixed material is processed to obtain the second mixed material;

[0028] The covering polymer, the pearl powder and the quartz sand are mixed with the second mixture, and a third mixture treatment is performed to obtain...

Embodiment 1

[0064] The present embodiment provides a kind of artistic paint, is made up of the component shown in following table 1:

[0065] Table 1

[0066]

[0067]

[0068] The preparation method of above-mentioned artistic paint comprises the following steps:

[0069] (1) Water is added to the reaction vessel, and at a rotating speed of 300 rpm, bentonite pre-dissolved slurry (a product obtained by high-speed dispersion of bentonite in water for 30 minutes, with a bentonite content of 2%) and cellulose are successively added, and dispersed for 5 minutes;

[0070] (2) Adjust the rotation speed to 800rpm, and put in pH regulator, dispersant, wetting agent, defoamer, antifreeze, emulsion, film-forming aid, preservative, anti-fungal agent and wax additive in sequence. Increase the rotation speed and disperse for 20 minutes;

[0071] (3) At a rotating speed of 500rpm, add covering polymer, pearl powder and quartz sand in sequence, adjust the rotating speed according to the stirrin...

Embodiment 2

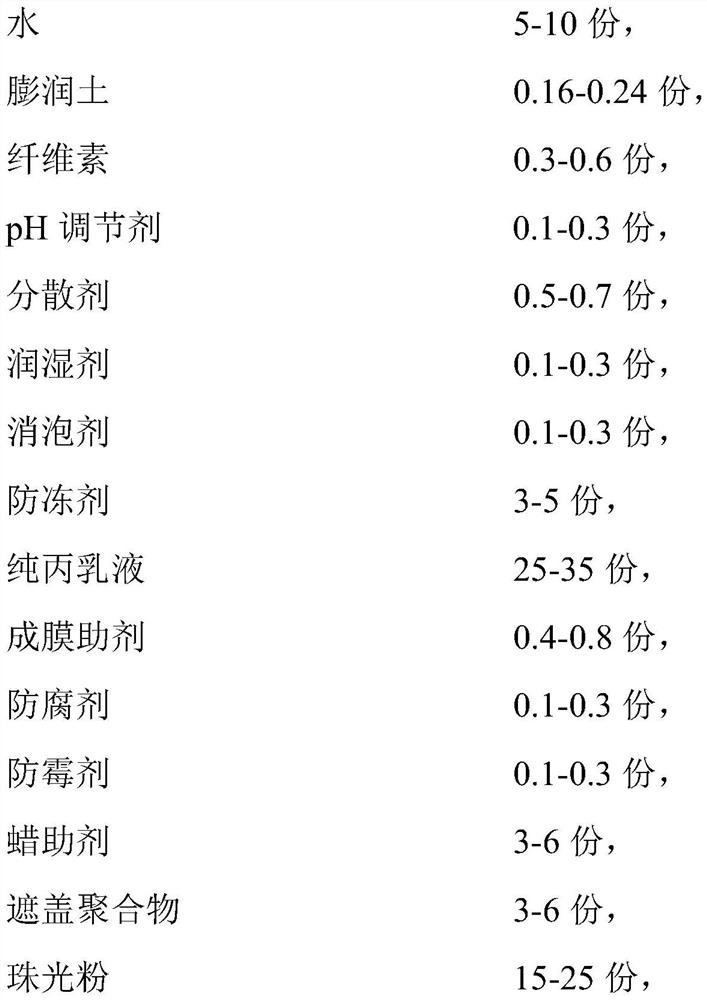

[0073] The present embodiment provides a kind of artistic paint, is made up of the component shown in following table 2:

[0074] Table 2

[0075]

[0076] The preparation method of above-mentioned artistic paint comprises the following steps:

[0077] (1) Water is added to the reaction vessel, and at a rotating speed of 400rpm, bentonite predissolved slurry (a product obtained by high-speed dispersion of bentonite in water for 30 minutes, with a bentonite content of 2%) and cellulose are successively added, and dispersed for 5 minutes;

[0078] (2) Adjust the rotation speed to 900rpm, and put in pH regulator, dispersant, wetting agent, defoamer, antifreeze, emulsion, film-forming aid, preservative, anti-fungal agent and wax additive in sequence. Increase the rotation speed and disperse for 25 minutes;

[0079] (3) At a rotating speed of 600rpm, add covering polymer, pearl powder and quartz sand in sequence, adjust the rotating speed according to the stirring state, stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com