A kind of rare earth red pigment and preparation method thereof

A red pigment and rare earth technology, applied in the direction of fibrous fillers, etc., can solve the problems of deterioration, color loss, instability, etc., and achieve the effect of low equipment requirements, easy industrial production, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention also relates to the preparation method of the above-mentioned rare earth red pigment, comprising the following steps:

[0029] (1) dissolving the soluble rare earth salt, soluble iron salt and soluble aluminum salt in water, adding a precipitating agent under stirring conditions, and standing still after stirring to obtain a suspension;

[0030] In one embodiment of the present invention, the stirring reaction time is 10-30 minutes, and the standing time is 1-3 hours. In order to completely precipitate the ions in the soluble metal salt, an excess amount of precipitant should be added in this step.

[0031] (2) solid-liquid separation is carried out to the suspension, and the solid phase is washed and dried to obtain a precipitate;

[0032] In one embodiment of the present invention, after the suspension is suction-filtered under reduced pressure, the obtained solid phase is washed with deionized water, ethanol, and deionized wat...

Embodiment 1

[0036] A red pigment doped with rare earth ions. The raw materials include, by weight, 5 parts of cerium nitrate, 30 parts of iron nitrate, 10 parts of aluminum nitrate and 30 parts of sodium hydroxide.

[0037] The rare earth red pigment is prepared by a liquid phase method, which specifically includes the following steps:

[0038] (1) dissolving cerium nitrate, ferric nitrate and aluminum nitrate in water, adding sodium hydroxide under stirring condition, stirring and reacting for 15 minutes and then standing for 2 hours to obtain a suspension;

[0039] (2) After the suspension is filtered under reduced pressure, the obtained solid phase is washed with deionized water, ethanol, and deionized water successively, and then vacuum-dried and ground to obtain a precipitate;

[0040] (3) calcining the precipitate at 800° C. for 60 min to obtain the rare earth red pigment.

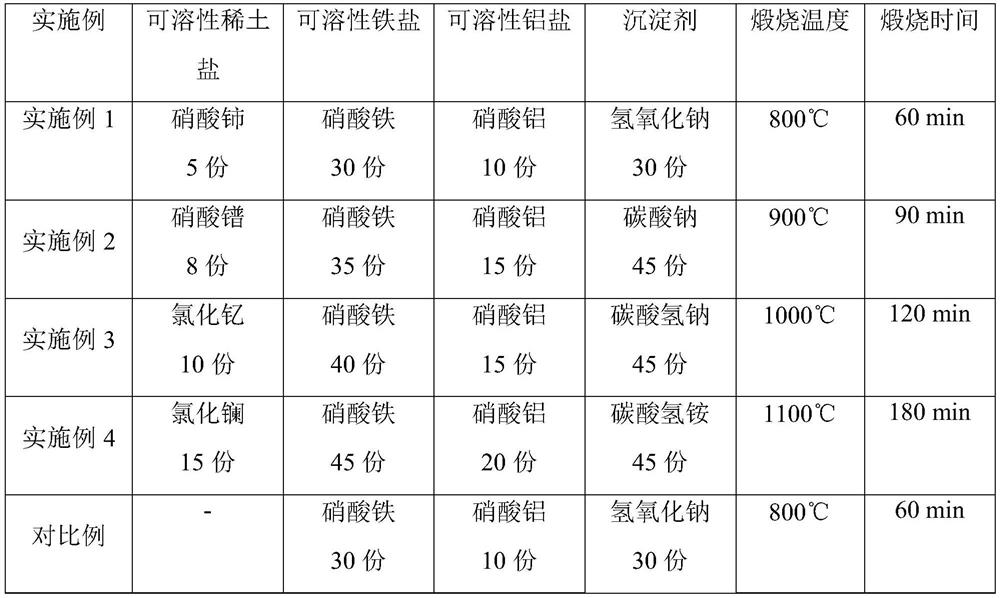

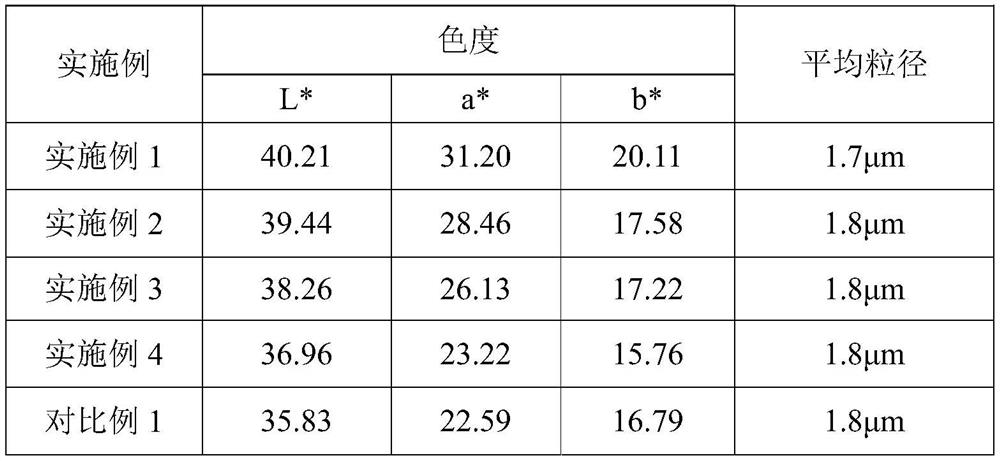

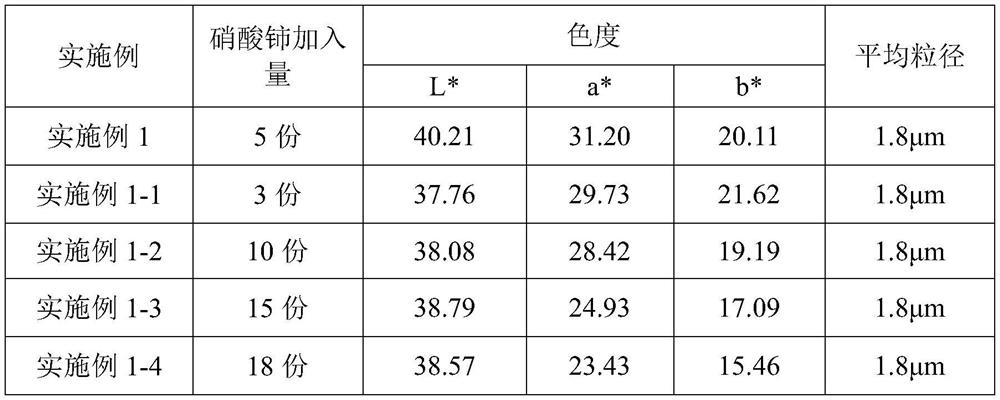

[0041] The raw material components and calcination conditions in Examples 2-4 and Comparative Example were c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com