Special material for preparing full-biodegradable mulching film, full-biodegradable mulching film prepared from special material and preparation method of mulching film

A degradable mulch film and all-biological technology, applied in the field of fully biodegradable agricultural films, can solve the problems of poor compatibility, poor weather resistance of products, and failure to meet production needs, etc., to achieve the effect of meeting the growth cycle, easy industrial production, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

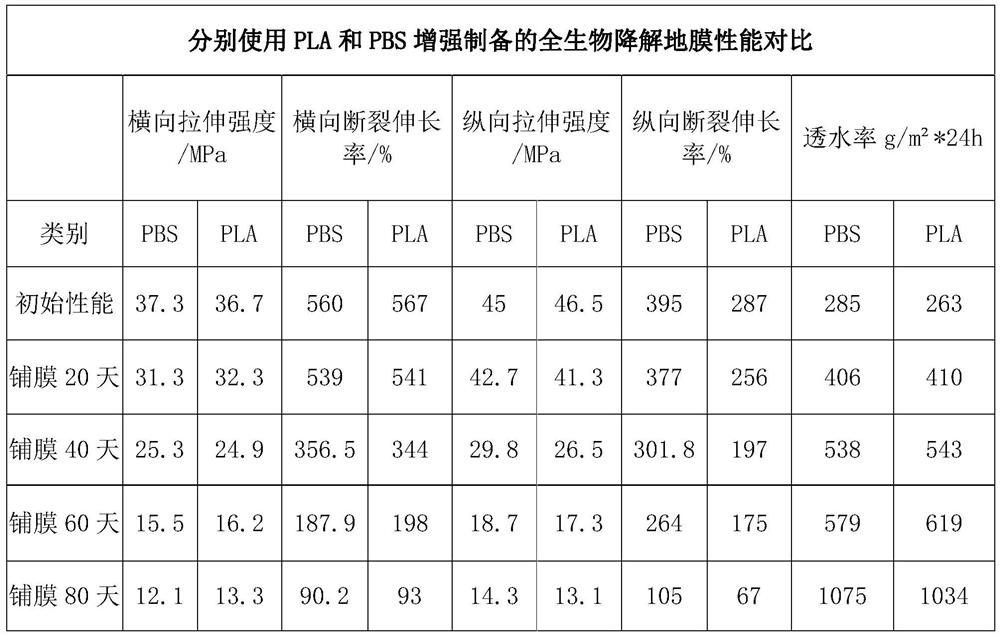

Embodiment 1

[0070] Example 1: This example discloses a method for preparing a fully biodegradable mulch film. The preparation method is as follows:

[0071] 1. Synthesis of fully biodegradable plastic film modifier

[0072] (1) Heat treatment of talc powder and nano-active calcium carbonate: bake talc powder and activated calcium carbonate at 105°C for 3 hours, then cool down to 58°C for 2 hours.

[0073] (2) Make black masterbatch: black masterbatch is extruded and granulated according to the ratio of carbon black and PBAT at 1:6.

[0074] (3) Heat drying and dehydration: heat drying PBAT, PPC, and color masterbatch at 58°C for 3 hours.

[0075] (4) Material mixing: 63.1 parts by weight of PBAT, 15 parts by weight of PBS, 3 parts by weight of PPC, 3 parts by weight of talcum powder, 5 parts by weight of nano-active calcium carbonate, 1 part by weight of liquid paraffin, 0.5 parts by weight of antioxidant 168, 6 parts by weight of black masterbatch, 0.6 parts by weight of UV326, 0.7 par...

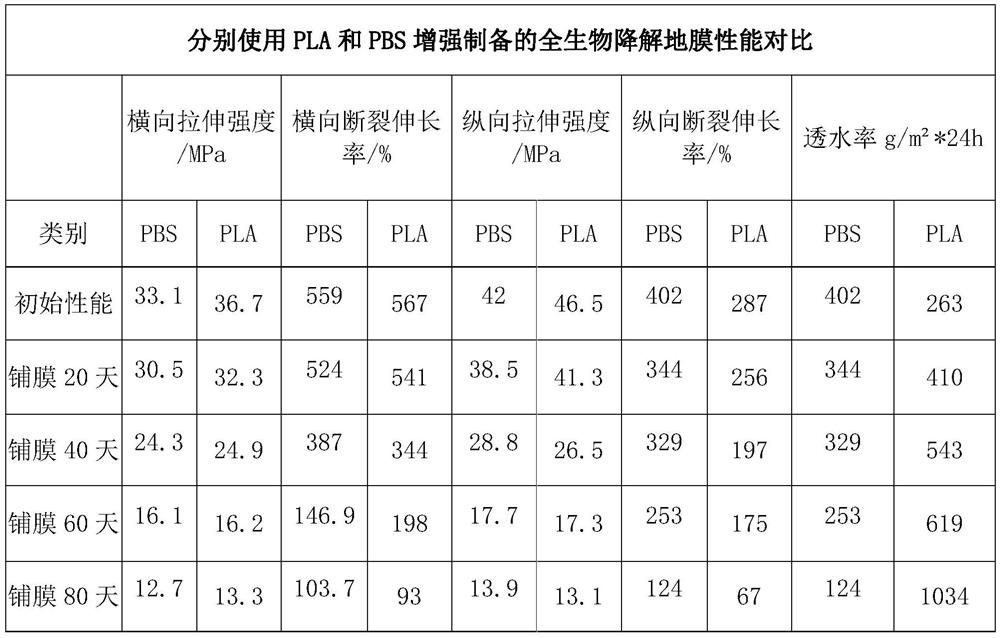

Embodiment 2

[0082] Example 2: This example discloses a method for preparing a fully biodegradable mulch film. The preparation method is as follows:

[0083] 1. Synthesis of fully biodegradable plastic film modifier

[0084] (1) Heat treatment of talc powder and nano-active calcium carbonate: bake talc powder and activated calcium carbonate at 105°C for 3 hours, then cool down to 58°C for 2 hours.

[0085] (2) Make black masterbatch: black masterbatch is extruded and granulated according to the ratio of carbon black and PBAT at 1:6.

[0086] (3) Heat drying and dehydration: heat drying PBAT, PPC, and color masterbatch at 58°C for 3 hours.

[0087] (4) Material mixing: 68.1 parts by weight of PBAT, 10 parts by weight of PBS, 3 parts by weight of PPC, 3 parts by weight of talcum powder, 5 parts by weight of nano-active calcium carbonate, 1 part by weight of liquid paraffin, 0.5 parts by weight of antioxidant 168, 6 parts by weight of black masterbatch, 0.6 parts by weight of UV326, 0.7 par...

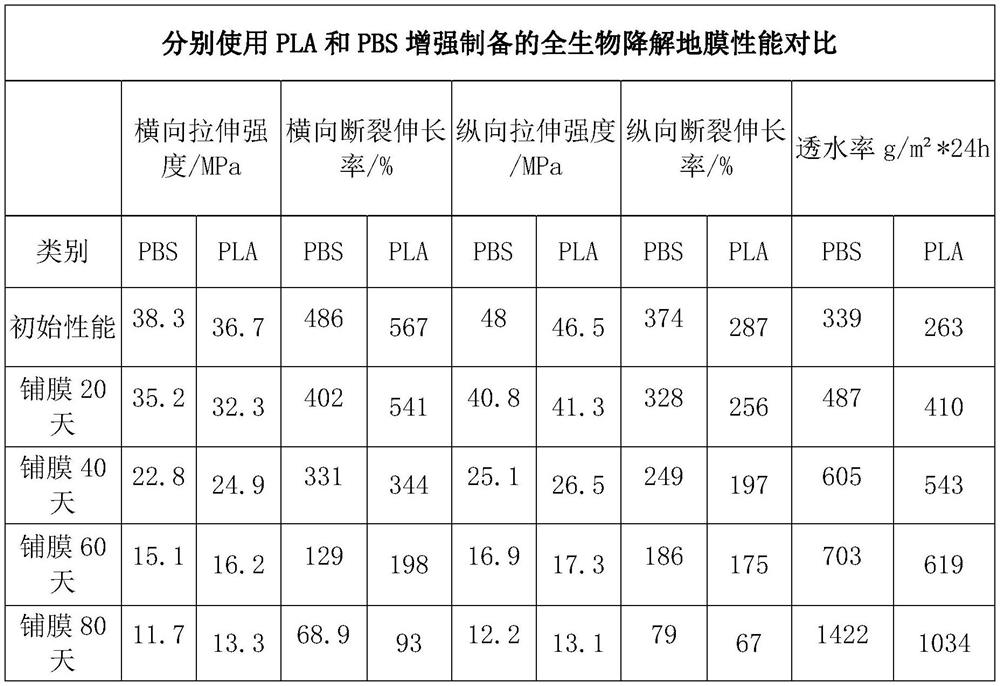

Embodiment 3

[0094] Embodiment 3: A kind of preparation method of fully biodegradable plastic film, preparation method is as follows:

[0095] 1. Synthesis of fully biodegradable plastic film modifier

[0096] (1) Heat treatment of talc powder and nano-active calcium carbonate: bake talc powder and activated calcium carbonate at 105°C for 3 hours, then cool down to 58°C for 2 hours.

[0097] (2) Make black masterbatch: black masterbatch is extruded and granulated according to the ratio of carbon black and PBAT at 1:6.

[0098] (3) Heat drying and dehydration: heat drying PBAT, PPC, and color masterbatch at 58°C for 3 hours.

[0099] (4) Material mixing: 58.1 parts by weight of PBAT, 20 parts by weight of PBS, 3 parts by weight of PPC, 3 parts by weight of talcum powder, 5 parts by weight of nano-active calcium carbonate, 1 part by weight of liquid paraffin, 0.5 parts by weight of antioxidant 168, 6 parts by weight of black masterbatch, 0.6 parts by weight of UV326, 0.7 parts by weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com