Propylene polymerization catalyst system and application thereof

A propylene polymerization and catalyst technology, which is applied in the application field of preparing high-rigidity heat-resistant polypropylene, can solve the problem of low-standard polypropylene, and achieve good rigidity-toughness balance, good economic promotion value, and good rigidity-toughness balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

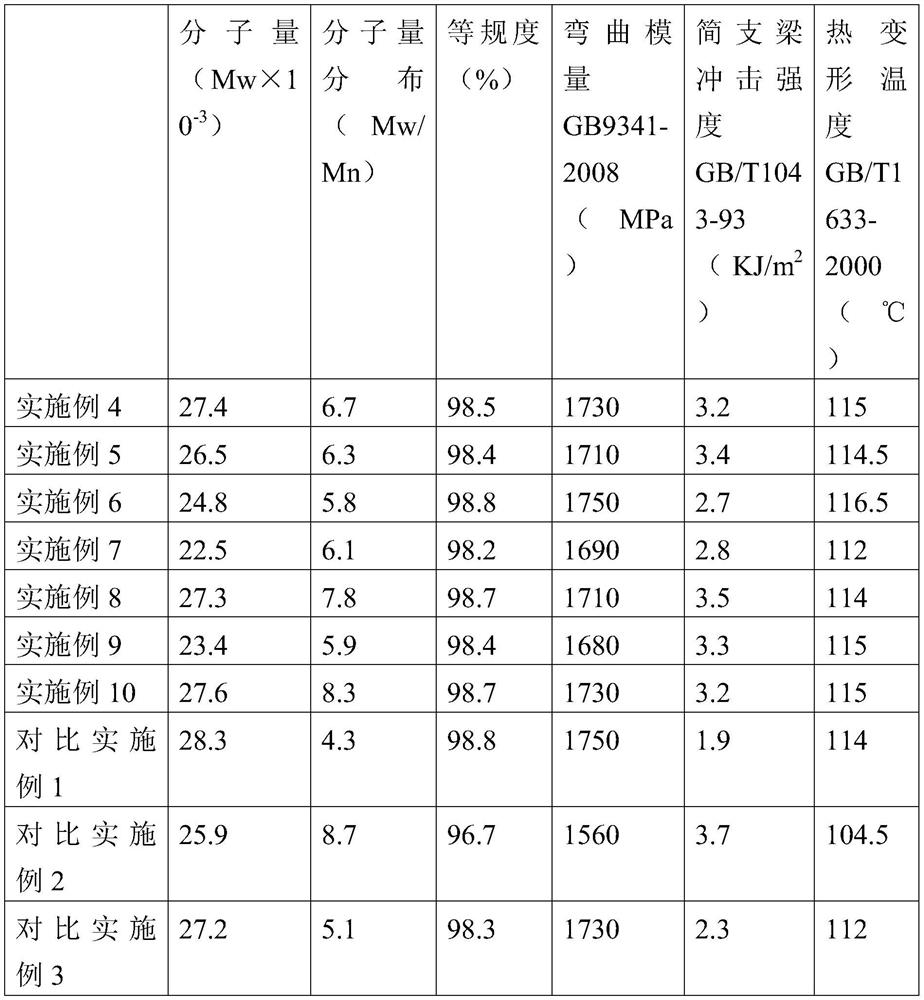

Examples

Embodiment 1

[0026] Solid component (A) is the preparation of main catalyst:

[0027] Under the protection of nitrogen, in a 500ml four-port glass reactor, at 0°C, first add 250ml of titanium tetrachloride, and then add 10g of magnesium chloride alcoholate (MgCl 2 *2.8C 2 h 5 OH) was added dropwise to the cooled titanium tetrachloride, and after the dropwise addition was completed, the temperature was raised to 120° C. to react for a predetermined time, left to stand, and suction filtered. After cooling down to room temperature, add 250ml of titanium tetrachloride, then raise the temperature to 100°C and add 2.05g (about 7.4 mmol) of diisobutyl phthalate (DIBP) as an internal electron donor, and react at this temperature for 1h. Raise the temperature to 120°C to react for a period of time, let stand, wash with toluene and n-hexane several times, and dry in vacuum to obtain free-flowing catalyst particles cat-1. Titanium content of solid catalyst component: 3.2%, ester content 12.7%.

Embodiment 2

[0029] Solid component (A) is the preparation of main catalyst:

[0030] Under the protection of nitrogen, in a 500ml four-port glass reactor, at 0 ° C, first add 250ml of titanium tetrachloride, and in the case of stirring, add 10g of magnesium chloride alcoholate carrier (MgCl 2 *2.8C 2 h 5 OH) was added dropwise to the cooled titanium tetrachloride, and after the dropwise addition was completed, the temperature was raised to 120° C. to react for a predetermined time, left to stand, and suction filtered. After cooling down to room temperature, add 250ml of titanium tetrachloride, then raise the temperature to 100°C and add 2.10g of di-n-butyl phthalate (DNBP) internal electron donor, react at this temperature for 1 hour, then raise the temperature to 120°C for a period of reaction time, let it stand, washed several times with toluene and n-hexane, and vacuum dried to obtain free-flowing catalyst particles cat-2. Titanium content of solid catalyst component: 2.8%, ester co...

Embodiment 3

[0032] Preparation of di-n-butyl 2-cyano-2,3-dimethylsuccinate:

[0033] Use S N 2 coupling for preparation, the preparation method can refer to the method used in CN1240729C.

[0034] Add 157 mmol 2-cyanopropionic acid to freshly prepared lithium diisopropylamide solution (41 mL, 314 mmol diisopropylamine and 126 mL of BuLi (2.5M in hexane; 314 mmol) and 1 L of tetrahydrofuran at 0 °C THF). The mixture was stirred at 0°C for 15 minutes and then stirred at 45°C for 4 hours, while in another reactor, 14.1ml (157mmol) of 2-bromopropionic acid and 28g (157mmol) of hexamethylphosphoryl A mixture of triamine HMPA was added to a suspension of 3.8 g (157 mmol) NaH in 500 mL THF while controlling gas evolution. After the addition, the mixture was stirred at 0°C for 15 minutes, then added to the above mixture of 2-cyanopropionate lithium salt at 0°C, and then stirred at 35°C for 2 hours. The mixture was rapidly cooled with 150 mL of NaCl-saturated 1 N HCl solution. The mixture was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com