Telescopic flying-dust-free ash discharging device

A kind of ash unloading device, telescopic technology, applied in the field of retractable dust-free ash unloading device, can solve the problems of short service life, poor dust suppression effect, environmental pollution, etc., achieve low production cost, convenient production and installation, reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the examples.

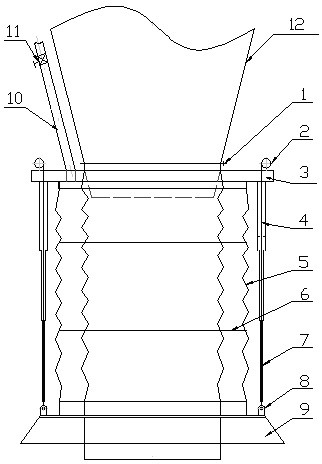

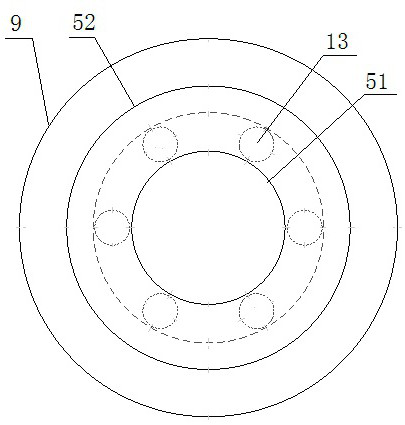

[0025] The invention discloses a retractable dust-free ash unloading device, see figure 1 , figure 2 , including flange 1, winch 2, upper platform 3, steel wire rope 4, nylon cloth 5, skeleton 6, telescopic rod 7, lifting lug 8, dust cover 9, dust removal pipe 10, flange 1 is installed on the upper platform 3, and the method The blue 1 is connected with the raw material hopper 12; a hoist 2 is installed on both sides of the upper platform 3, and a dust removal pipe 10 is installed on the upper platform 3 between one hoist 2 and the raw material hopper 12; The bottom of 3 is equipped with telescopic rod 7 and nylon cloth 5, and telescopic rod 7 is positioned at upper platform 3 both sides and cooperates with the wire rope 4 of hoist 2, and the wire rope 4 of hoist 2 is positioned at telescopic rod 7; Nylon cloth 5 circumferential direction is arranged on the top Below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com