Flexible low-frequency wave-absorbing plate and preparation method thereof

A flexible, low-frequency technology, applied in the field of flexible low-frequency wave-absorbing sheets and its preparation, can solve the problems of unsuitable promotion and application, high cost, narrow absorption bandwidth, etc., and achieve industrial application, high production efficiency, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

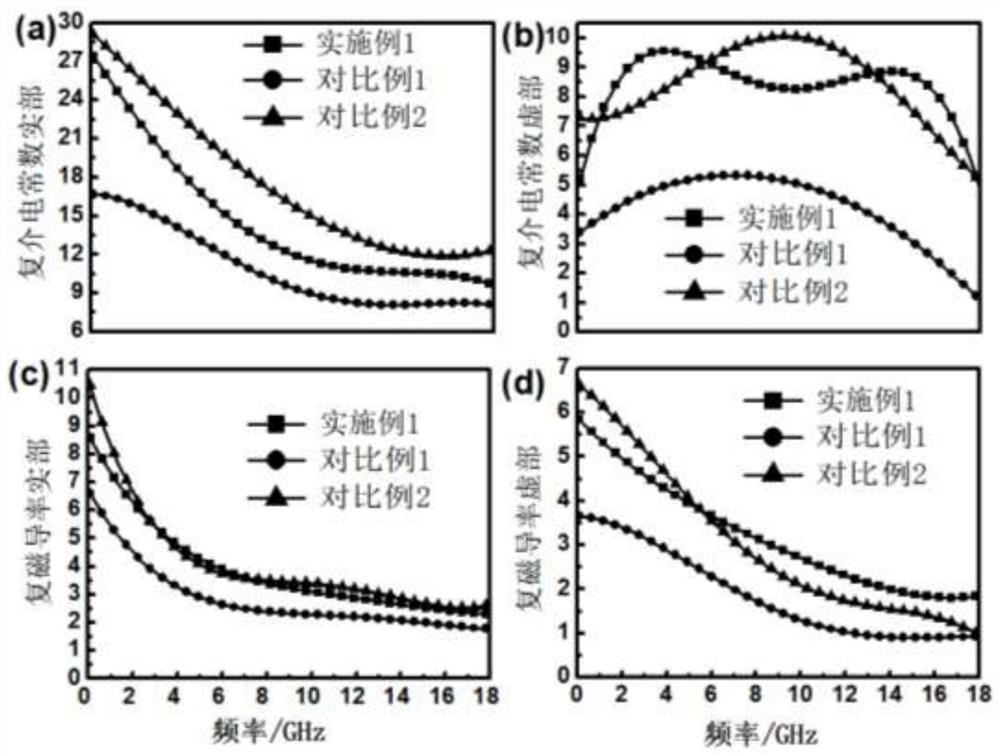

Embodiment 1

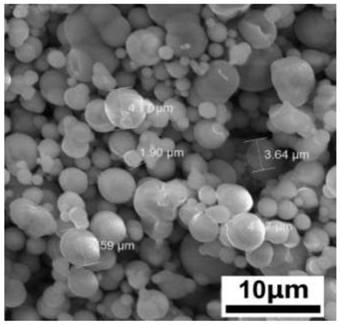

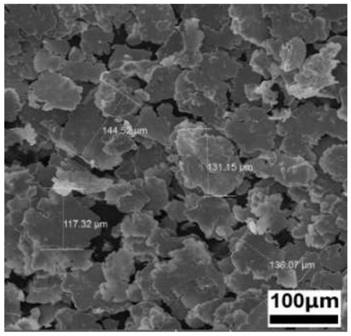

[0029] In the flexible low-frequency wave-absorbing sheet of this embodiment, the rubber is polyurethane elastomer, and the functional additives filled include flame retardant, wetting and dispersing agent, vulcanizing agent and plasticizer. The first and third layers of rubber films are filled with D50= 3.27μm spherical nickel carbonyl magnetic powder with a thickness of 0.3mm, the second and fourth layers of rubber film are filled with two-dimensional flake FeCoZr magnetic powder with D50=126.81μm and the thickness is 0.2mm, the total thickness of the flexible low-frequency wave absorbing sheet is 1.0mm.

[0030] The preparation method of the flexible low-frequency wave-absorbing sheet comprises the following steps:

[0031] (1) Mix 0.5kg polyurethane rubber particles, 0.1kg flame retardant, 0.02kg wetting and dispersing agent, 0.02kg

[0032] Vulcanizing agent, 0.01kg plasticizer and 3.0kg are evenly divided into two parts, one part is added with spherical nickel carbonyl ...

Embodiment 2

[0043] In this embodiment, the rubber is nitrile rubber elastomer, and the functional additives filled include flame retardant, wetting and dispersing agent, leveling agent and vulcanizing agent. μm and 2.39μm spherical FeCo magnetic powder and FeNi magnetic powder and the thickness of both layers is 0.35mm, the second and fourth layers of rubber film are filled with flake FeNiMo magnetic powder and flake FeSiCr magnetic powder with D50 of 118.34μm and 109.26μm respectively and two layers The thickness is 0.3mm, and the total thickness of the flexible low-frequency wave-absorbing sheet is 1.3mm.

[0044] The preparation method of the above-mentioned flexible low-frequency wave-absorbing sheet comprises the following steps:

[0045] (1) Divide 0.7kg of nitrile rubber particles, 0.15kg of flame retardant, 0.02kg of wetting and dispersing agent, 0.01kg of leveling agent and 0.03kg of vulcanizing agent into two, and add 1.5kg of spherical FeCo magnetic powder, 1.0 kg spherical Fe...

Embodiment 3

[0052] In this embodiment, the rubber is EPDM elastomer, and the functional additives and powders filled include flame retardant, wetting and dispersing agent, leveling agent and vulcanizing agent, and the first and third layers of rubber films are filled with Spherical nickel carbonyl powder with particle size D50 of 4.02μm and both layers of thickness are 0.5mm, the second and fourth layers of rubber film are filled with flaky FeSi with D50 of 97.68μm and both layers of thickness are 0.25mm, flexible low frequency absorbing sheet The total thickness is 1.5mm.

[0053] The preparation method of the above-mentioned flexible low-frequency wave-absorbing sheet comprises the following steps:

[0054] (1) Divide 0.6kg of nitrile rubber granules, 0.15kg of flame retardant, 0.03kg of wetting and dispersing agent, 0.01kg of leveling agent and 0.03kg of vulcanizing agent into two, and add 2.5kg of spherical nickel carbonyl powder to one part, Add 1.0 kg of two-dimensional flake FeSi ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com