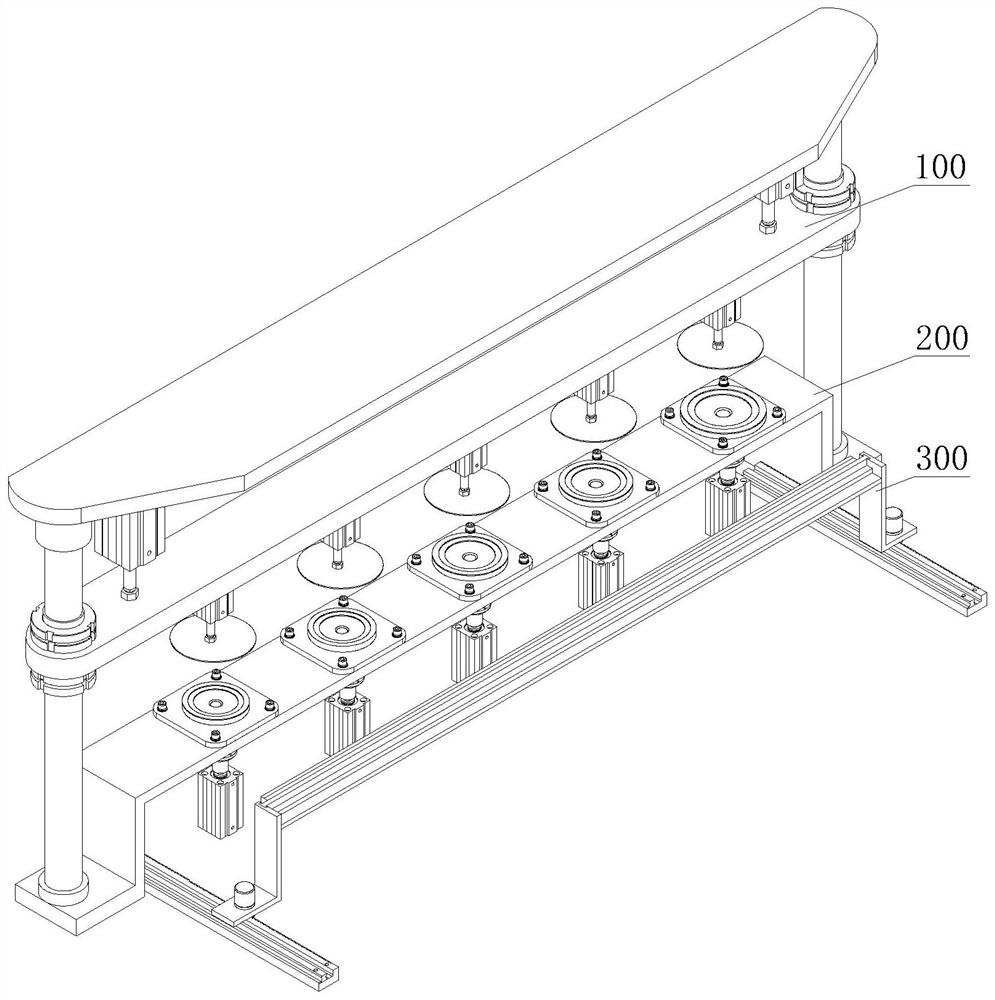

Lithium battery cap shell forming device and implementation method thereof

A molding device, lithium battery technology, applied in the direction of battery cover/end cover, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of prolonged processing cycle, waste of processing time, complicated processing procedures, etc., to improve processing quality, Reduced time to change processing equipment, ease of use and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0053] refer to Figure 10 , in order to better demonstrate the flow of the lithium battery cap shell forming device, this embodiment now proposes an implementation method of the lithium battery cap shell forming device, including the following steps:

[0054] S101: Feeding, put the flat material into the stepped groove 222 from the left side of the device, the flat material covers the light sensor 240; the light sensor 240 transmits the information to the controller through the wireless signal, and the controller sends an instruction after receiving the information The information starts to drive the air pump to run, and the light sensor 240 is used to sense and start the processing, with a high degree of automation;

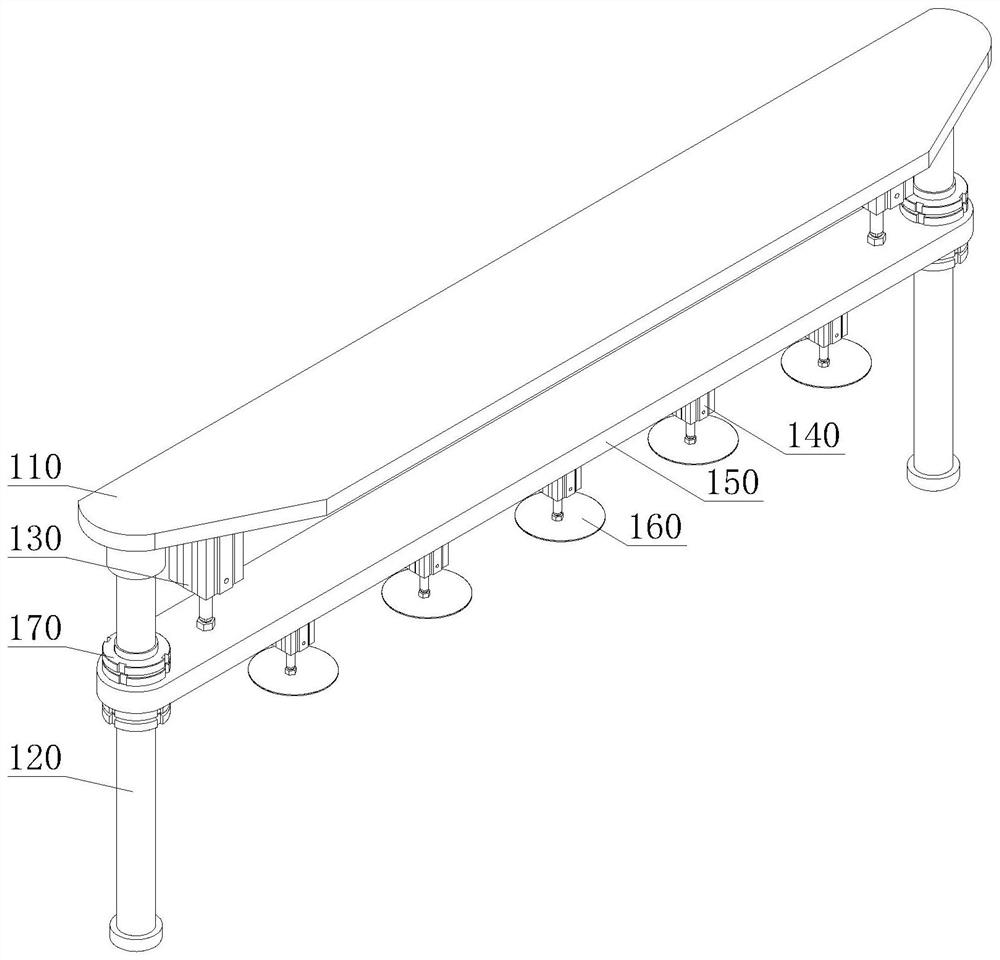

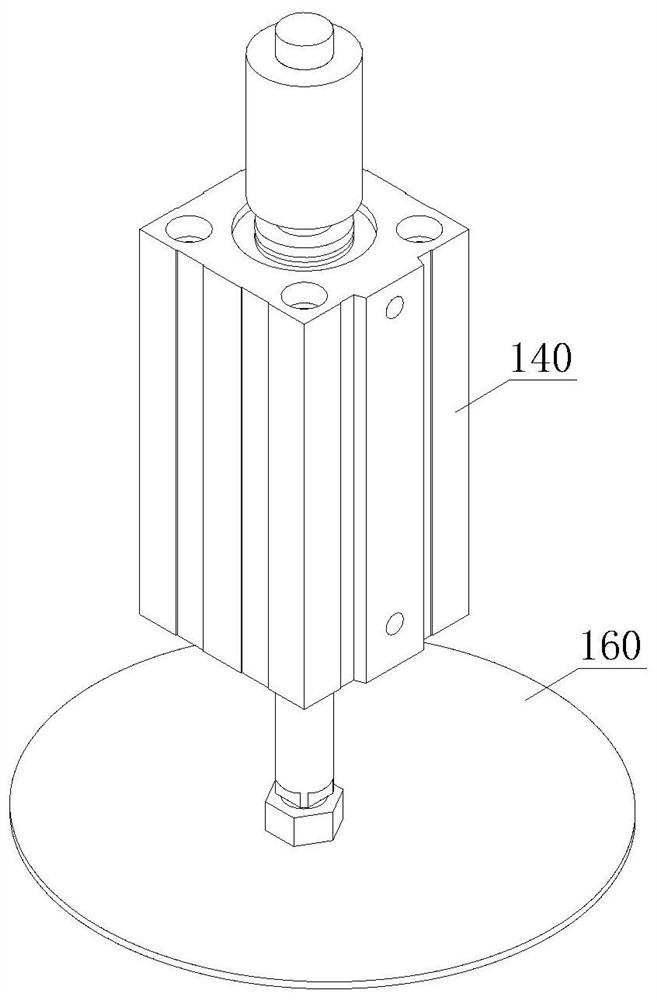

[0055] S102: Pressing and cutting, after the light sensor 240 detects that the raw material is in place, the air pump drives the main push cylinder assembly 130 to press down, and presses and cuts the raw material along the outer diameter of the stepped groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com