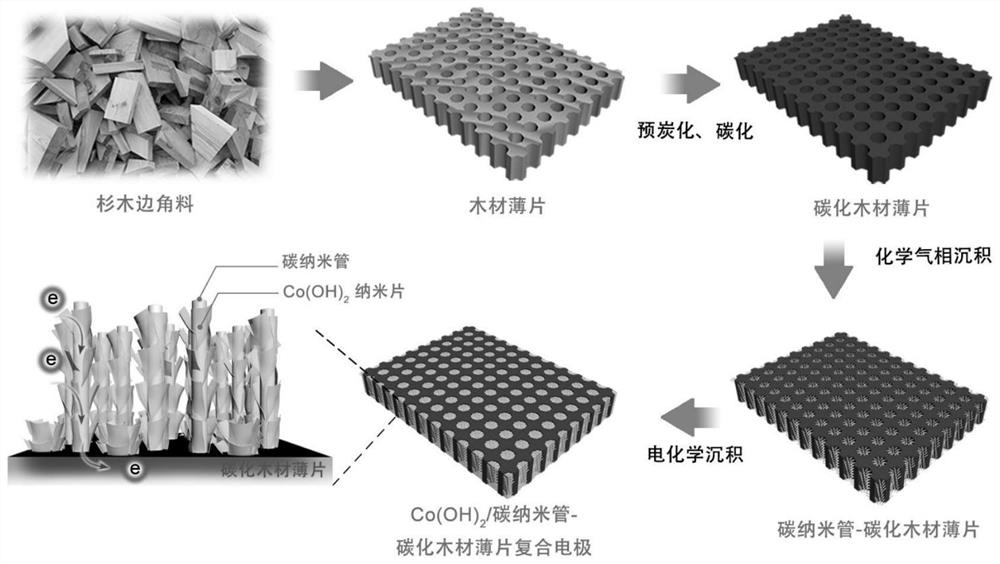

Electrode material based on multi-walled carbon nanotube-carbonized wood mixed support, preparation method thereof and supercapacitor

A technology of multi-walled carbon nanotubes and hybrid scaffolds, which can be used in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors, and can solve the problems of difficult structure modification of carbonized wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this embodiment, the preparation method of the electrode material based on the multi-walled carbon nanotube-carbonized wood hybrid support includes the following steps: 1) Preparation of MWCNT-CW support

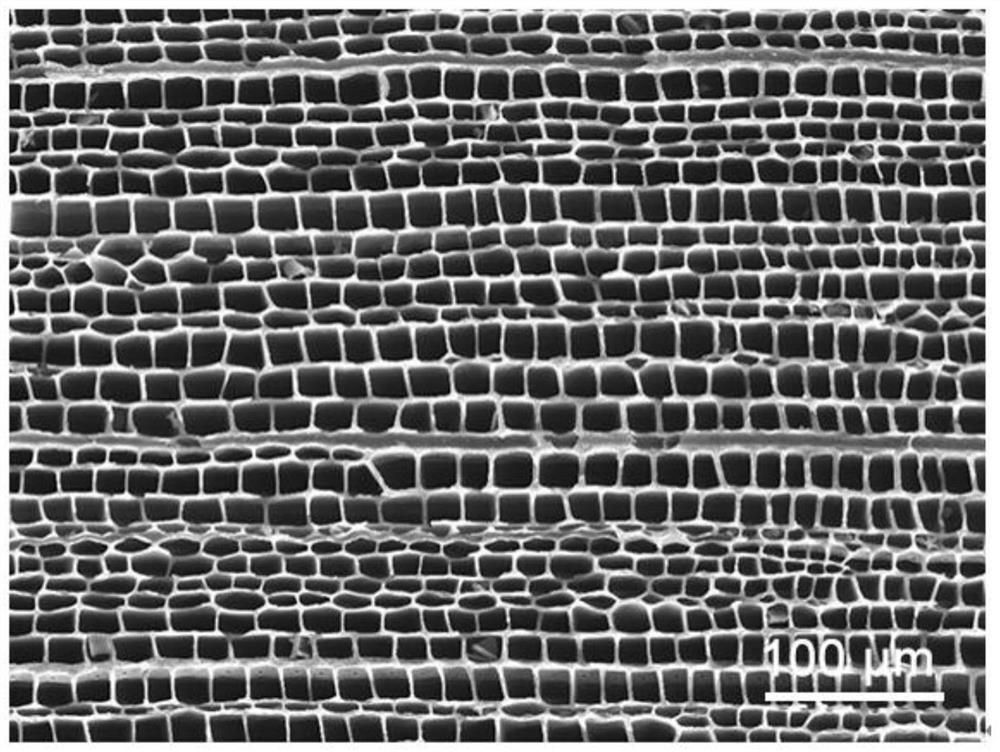

[0067] Chinese fir slices were purchased from Shaodong County, Hunan Province, China. After drying in a blast drying oven at 250°C for 6 hours for pre-carbonization, the wood chips were placed in a tube furnace and heated to 1000°C for 6h under the protection of Ar gas, and then carbonized with CO at 750°C. 2 (80sccm) gas activation for 10h. The activated carbonized wood is beaten into 0.5 mm thin slices with 2000 mesh sandpaper, washed with 6% HCl for 20 minutes, and then washed several times with deionized water until the cleaning solution becomes clear, and then placed in a blast drying oven at 80 ° C. dry. The obtained carbonized wood chips were heated at 90°C in Ni(NO 3 ) 2 solution (0.25mol / L) for 15 minutes, and then dried in air. The slices were then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com