In-situ biochar-soil mineral composite sample collection method

A technology for sample collection and biochar, which is applied in the fields of biochemical equipment and methods, biofuels, and sample preparation for testing, etc. The effect of small workload and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 prepares carbon film

[0022] The fired wheat straw charcoal (for the preparation method of biochar, please refer to the literature "Bao Lei et al., Research progress in the preparation and application of biochar materials, new chemical materials [J], 2019, 47(7): 54-59") Grind and pulverize evenly in a mortar, grind and pulverize, and pass through a 280-mesh sieve to obtain wheat straw biochar powder (hereinafter referred to as "charcoal powder").

[0023] Take 0.2g of charcoal powder and add 100 μL of 2% binder PVDF and 200 μL of solvent N-methylpyrrolidone into a mortar, mix to obtain a viscous coating, and spread the coating evenly on a surface 12 cm long and wide One side surface of 6cm graphite paper (base); after smearing, put the graphite paper in an oven at 85°C to dry for 1 hour, then put the graphite paper in an oven at 120°C to dry for 3 hours, take it out and cool to room temperature, After the paint dries, a coating is formed on the surface o...

Embodiment 2

[0029] Embodiment 2 Soil in-situ test

[0030] The present embodiment adopts the soil in-situ collection method, and the specific operation steps are as follows: dig a small rectangular ditch with a shovel or shovel according to the placement depth of the carbon film (slightly larger than the carbon film, if the burial depth exceeds the height of the carbon film, it can be placed in the soil layer surface markings).

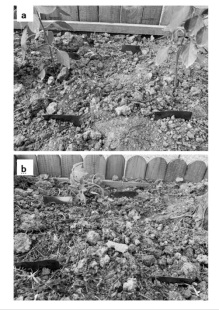

[0031] Insert the prepared carbon film vertically into the natural soil in the field, and at the same time ensure that the surface of the carbon film coating is in full contact with the soil. The soil must completely cover the surface of the carbon film so that the carbon film on the graphite paper is completely covered by the soil. The distance between each carbon film is about 10cm (such as figure 2 shown).

[0032] At installations 15d and 30d, the carbon film was carefully removed by digging a pit near the carbon film while pushing it sideways without rota...

Embodiment 3

[0048] Embodiment 3 binding agent screening test

[0049] In this example, the binder phenolic resin PF is used instead of the PVDF used in Example 1 to prepare a pure carbon-carbon membrane, and the rest of the preparation steps are the same as in Example 1.

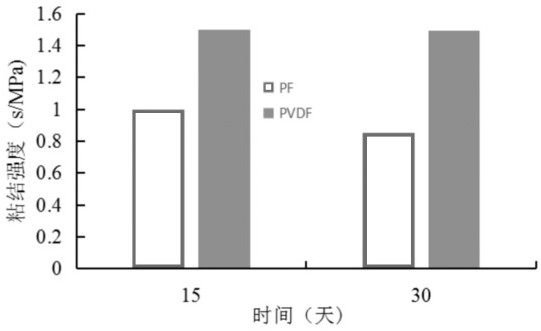

[0050] Detect the bond strength of coating and graphite paper after 15 days and 30 days respectively, and the method of bond strength detection can be found in literature (Zhang Feng et al. 2017, Influence of composition and heat treatment temperature on the bond performance of phenolic resin-based binder, Journal of Ceramics [ J], 38(5), 688-691). Test results such as image 3 shown.

[0051] Depend on image 3 It can be seen that with the prolongation of time, the bond strength of phenolic resin PF decreases, and a small part of carbon particles fall off after 30 days, which is not suitable for long-term field testing, while PVDF has strong adhesion and can prevent carbon particles for a long time. Grains fall off...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com