Fabricated building external wall heat preservation device

A technology for building exterior walls and thermal insulation devices, applied in building thermal insulation materials, thermal insulation, construction and other directions, can solve the problems of easy heat loss and poor thermal insulation effect of buildings, and achieve the effects of good thermal insulation effect, improved thermal insulation effect, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

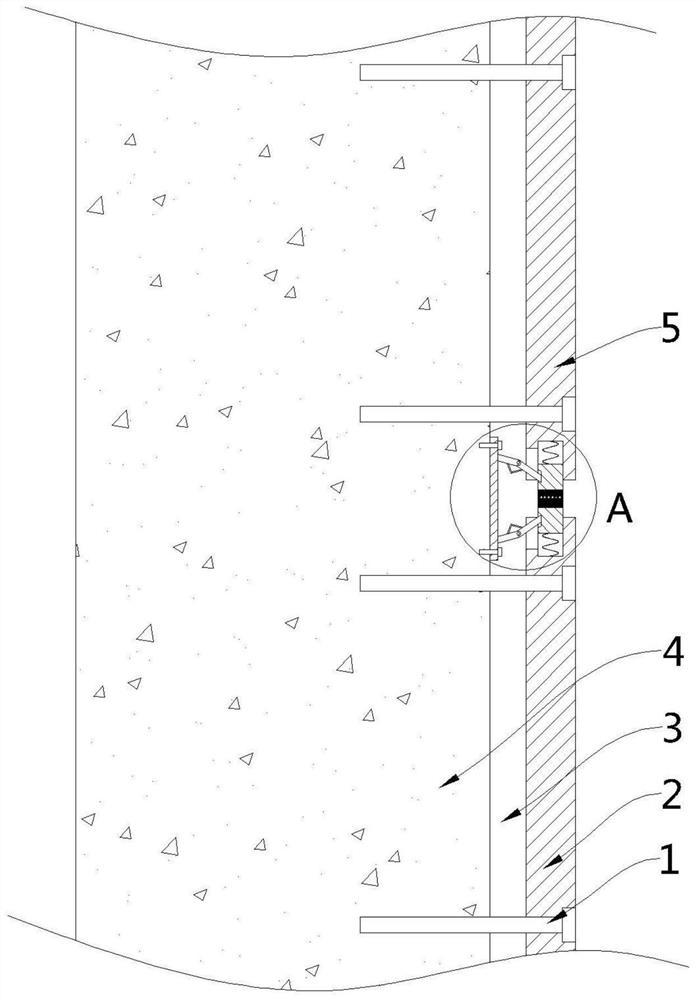

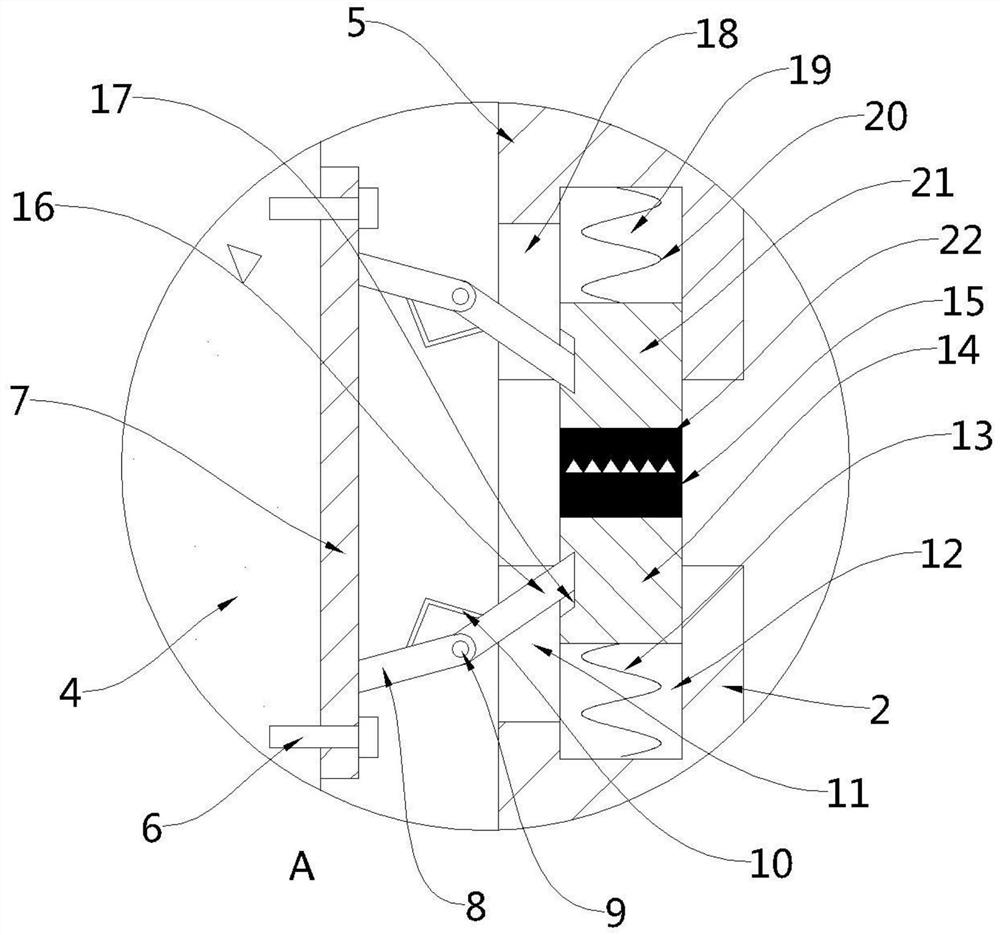

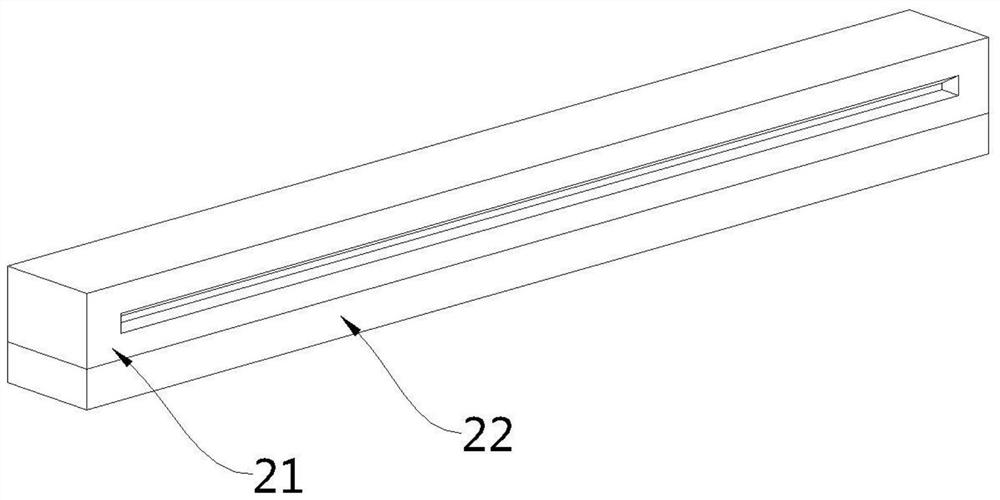

[0024] see Figure 1-3 , this embodiment provides a prefabricated building exterior wall thermal insulation device, including a wall 4, a second thermal insulation wall panel 5 and a first thermal insulation wall connected up and down on the side wall of the wall 4 by first bolts 1 plate 2, the first sealing assembly is movably installed on the side of the first thermal insulation wall panel 2 facing the second thermal insulation wall panel 5, and the second sealing assembly is movably installed on the side of the second thermal insulation wall panel 5 facing the first thermal insulation wall panel 2 The sealing assembly, specifically, the first sealing assembly includes a first cavity 12 opened on the side wall of the first thermal insulation wallboard 2 and a first cavity 12 connected inside the first cavity 12 through a first elastic body 13 A support plate 14, one end of the first support plate 14 extends to the outside of the first thermal insulation wall panel 2 and is f...

Embodiment 2

[0035] see figure 1 , a prefabricated building exterior wall insulation device, compared with Embodiment 1 in this embodiment, an insulation layer 3 is also provided between the first insulation wall panel 2 and the second insulation wall panel 5 and the wall body 4 , the thermal insulation layer 3 is made of thermal insulation material, such as thermal insulation cotton.

[0036] The embodiment of the present invention has the advantages of convenient installation and good thermal insulation effect. Compared with the prior art, the gap between adjacent thermal insulation wall panels can be greatly reduced, thereby preventing the internal heat of the building from being thermally insulated from two adjacent groups. Loss between the wallboards; by fixing the first thermal insulation wallboard 2 and the second thermal insulation wallboard 5 to the side wall of the wall body 4 through the first bolt 1 respectively, in the process of tightening the first bolt 1, the first thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com