Iron and steel metallurgical furnace

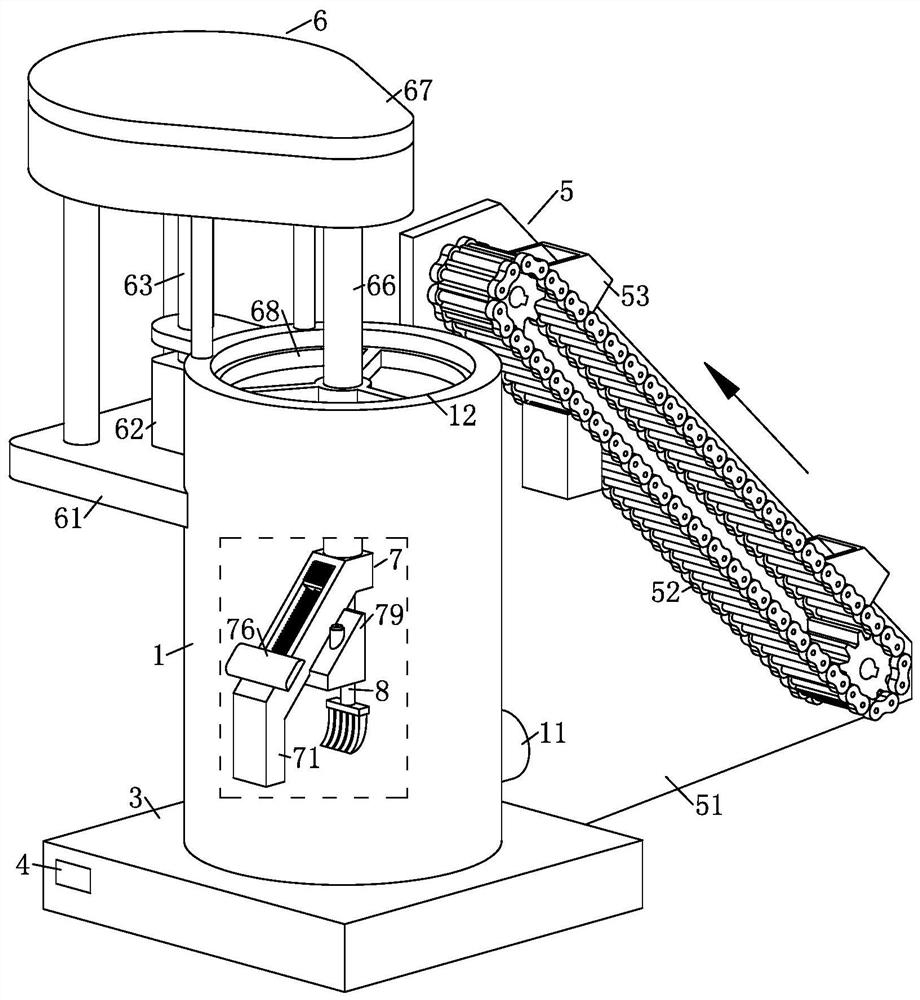

A technology for iron and steel metallurgy and furnace shell, applied in the field of iron and steel metallurgy furnaces, can solve the problems of continuous smelting due to wrong feeding, reduced melting efficiency of long steel bars, damage to refractory layers, etc., and achieves the effect of ensuring normal use, improving melting efficiency and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

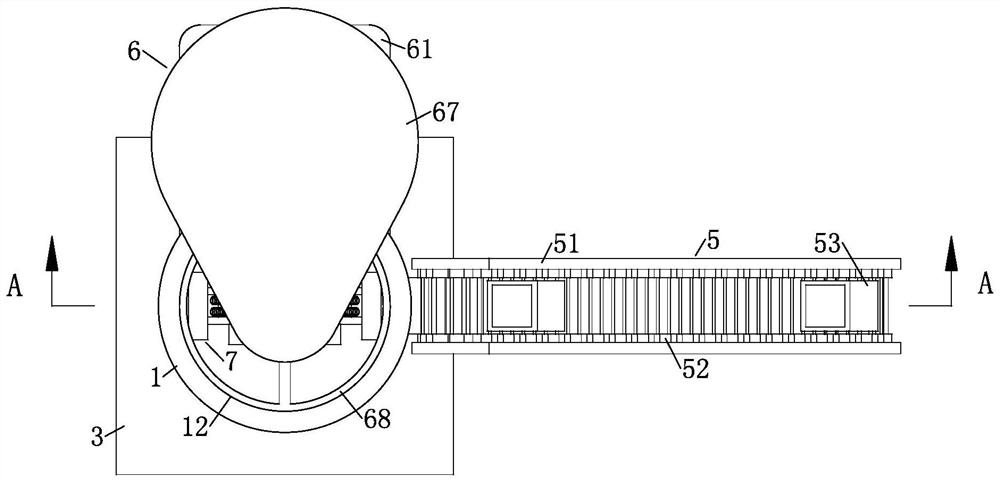

Examples

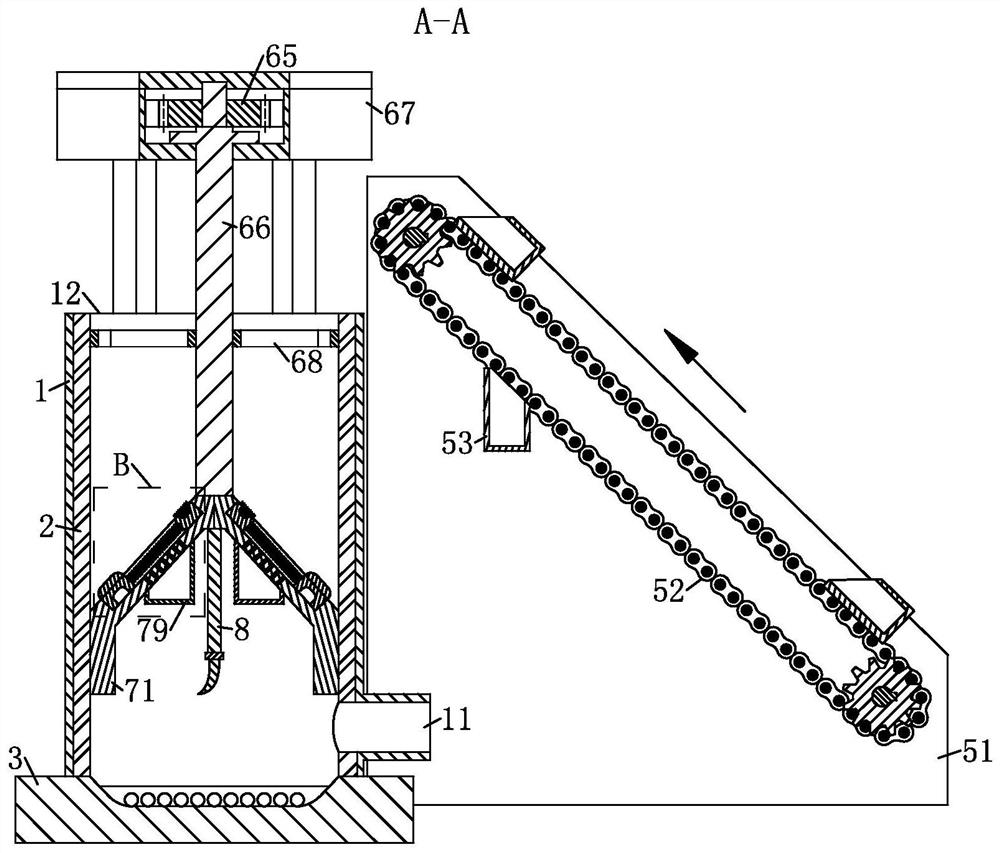

Embodiment approach

[0036] As an embodiment of the present invention, the inclined end of the distribution plate 71 is provided with a chute 72, and the chute 72 is provided with a No. 1 slider 73 and a No. 2 slider 74. The No. 1 slider 73 and No. 2 slide block 74 are slidably connected with chute 72, wherein No. 1 slide block 73 is located at the upper end of chute 72, No. 2 chute 72 is located at the lower end of chute 72, and between No. 1 chute 72 and No. 2 chute 72 There is a buffer spring 75 fixedly connected between them; when working, it is easy for the waste material to fall too fast and collide with the inner wall of the refractory layer 2, resulting in damage to the refractory layer 2; in order to solve this problem, the present invention is provided with a No. Slide block 73 and No. 2 slide block 74, when waste material falls and collides with No. 1 slide block 73, waste material promotes No. 1 slide block 73 compression buffer spring 75, under the effect of No. 1 slide block 73 and bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com