Material distributing mechanism of LED light splitting machine

A technology of a material separation mechanism and a spectroscope, which is used in sorting and other directions, can solve the problems of loss of parts such as the rotating shaft drive motor of the material separation head, unstable operation of the equipment, complicated installation structure, etc. The effect of stable operation and simple installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the embodiment of the invention is not limited thereto.

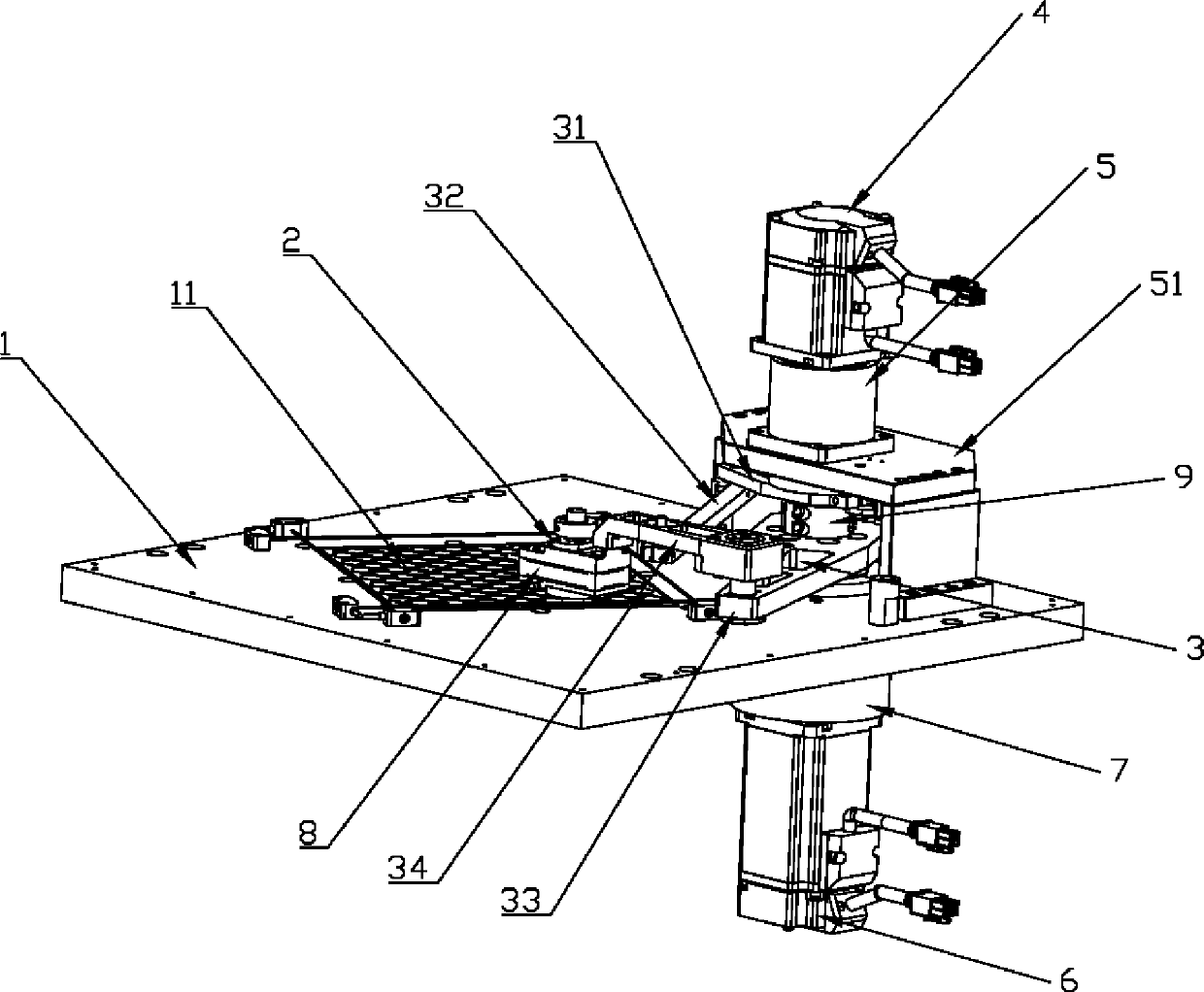

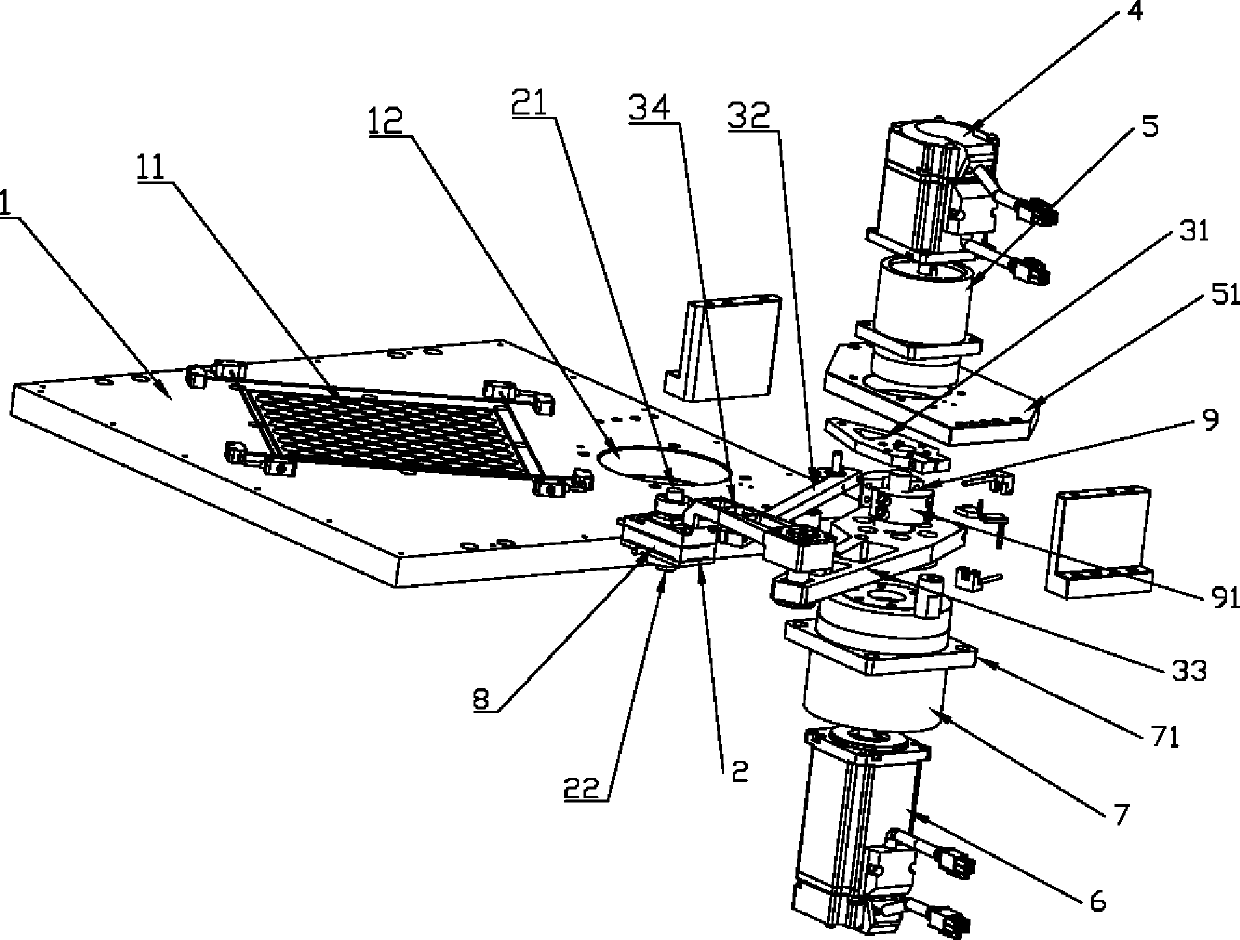

[0035] The specific embodiment of the material distributing mechanism of the invented LED spectrometer is as follows: figure 1 and figure 2 As shown, the material distribution bottom plate 1 is included, and the material distribution bottom plate 1 is provided with a plurality of material distribution holes 11, and each material distribution hole 11 is connected to a correspondingly classified material holding pipe;

[0036] The distributing mechanism also includes a four-bar mechanism 3, a distributing head device 2 connected to the four-bar mechanism 3, and a driving device that drives the four-bar mechanism 3 to move on the XY plane on the material distribution base plate 1, see figure 1 As shown, the XY plane is figure 1 The plane where the middle distribution hole 1 is located.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com