A spring feeding device of a universal head assembly machine

A technology of feeding device and head group, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of not being able to ensure that the puller spring is accurately dropped, and achieve the effect of saving equipment production costs and ensuring synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the utility model is described below with reference to accompanying drawing. In order to fully understand the utility model, many details are described below, but for those skilled in the art, the utility model can be realized without these details. Known components, methods and processes will not be described in detail below.

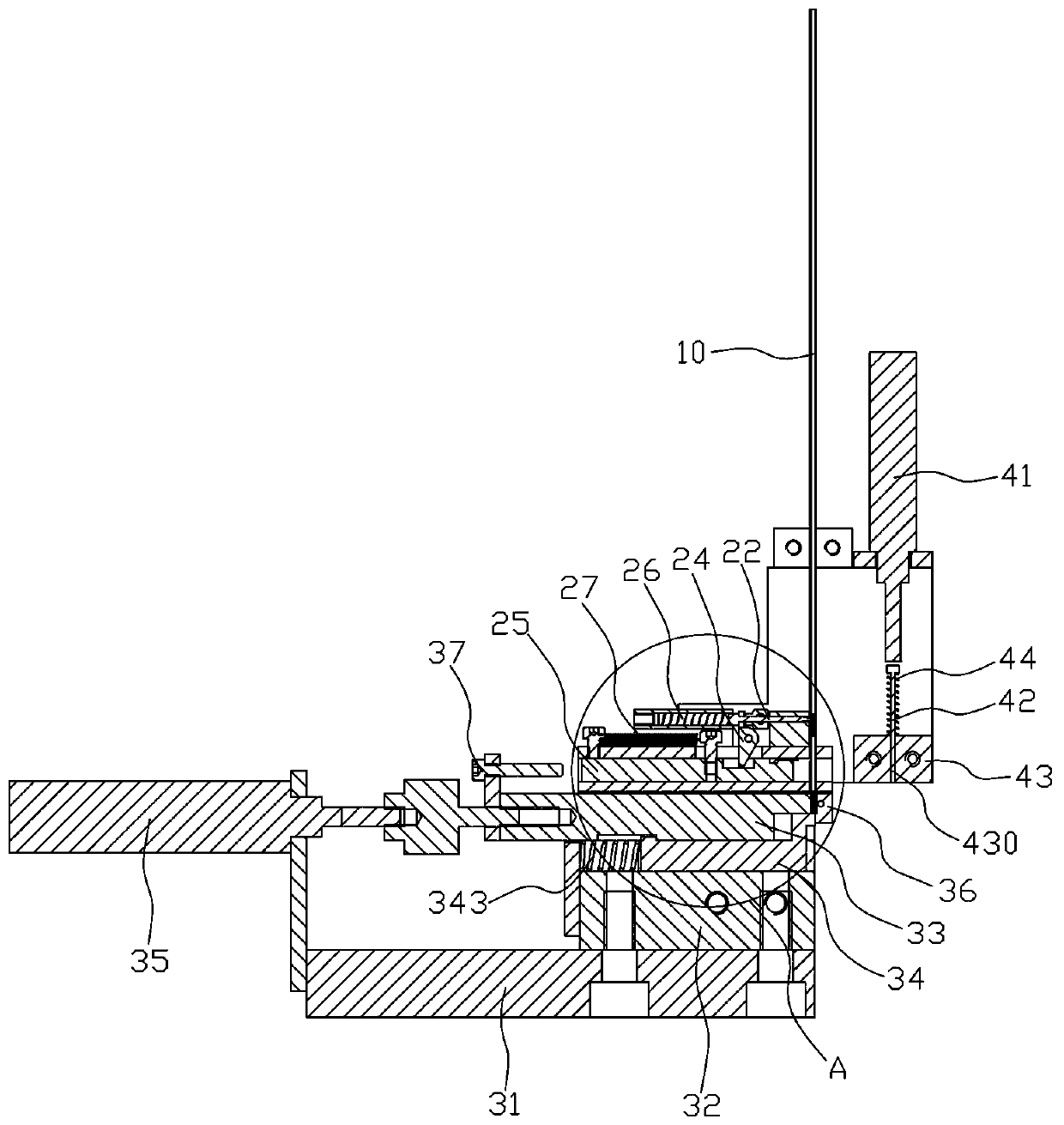

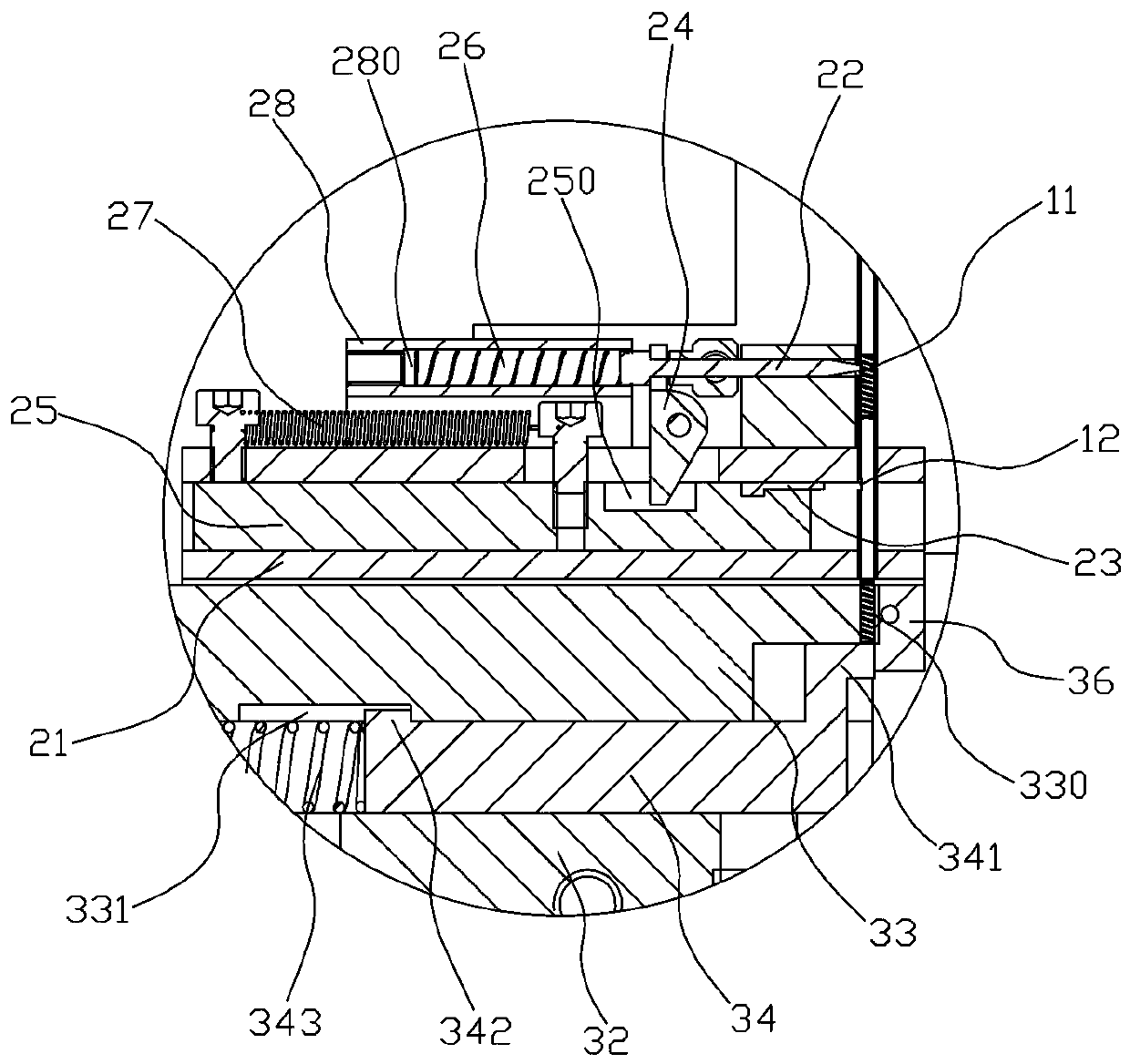

[0025] A spring feeding device of a universal head assembly machine, refer to Figure 1 to Figure 3 , including a spring track 10, a material distribution mechanism 20, a horizontal pushing mechanism 30 and a vertical pushing mechanism 40. Distributing mechanism 20 comprises guide seat 21, thimble 22, support sheet 23, material distribution pendulum block 24 and material distribution push block 25, and the bottom of spring rail 10 is provided with thimble hole 11 and support hole 12, and on described guide seat 21 A guide groove is provided, and the described material distribution push block 25 is slidably arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com