Machining process of low-deformation aluminum alloy welding aviation part

A processing technology, aluminum alloy technology, applied in welding accessories, metal processing equipment, welding equipment and other directions, can solve problems such as insufficient, deformation and sealing of parts, and achieve the effect of avoiding blackening, good sealing, and avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

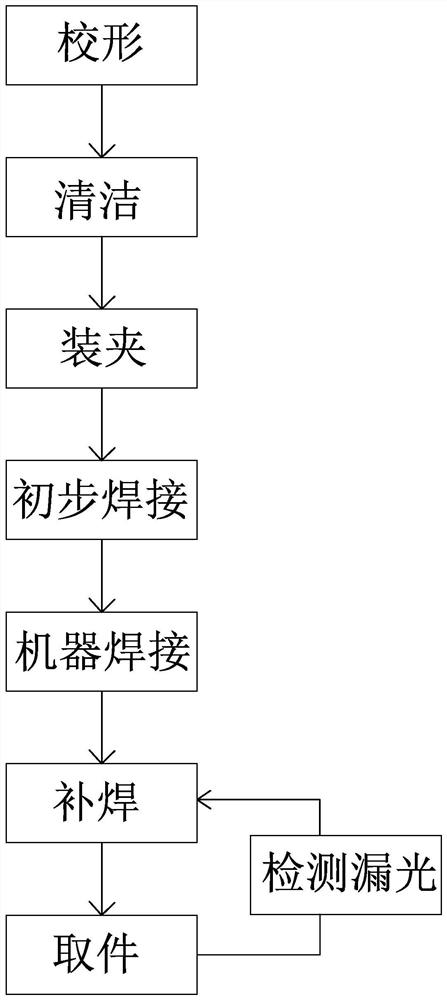

[0024] Such as figure 1 As shown, a low deformation aluminum alloy welding aviation parts processing technology, including the following steps:

[0025] S1. Shaping: Use a scraper or file to remove the burrs on the four sides of the cover and the box body, and use a small hammer to knock the four sides of the cover inward to make it slightly bend inward into an arc, and shape the four rounded corners of the cover and the box body to The transition is consistent, with no dislocation;

[0026] S2. Cleaning: Use acetone to wipe the lid and the box body to be welded clean;

[0027] S3. Clamping: Put the box body and cover into the tooling. After the box body and cover are placed in place, make the box body stretch from the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com