A fully automatic plastic box washing and drying machine

A fully automated, drying machine technology, applied in the direction of dryers, drying, local mixing dryers, etc., can solve problems such as trouble, poor effect, waste of water resources, etc., to achieve the goal of reducing waste, good effect, and saving heat energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

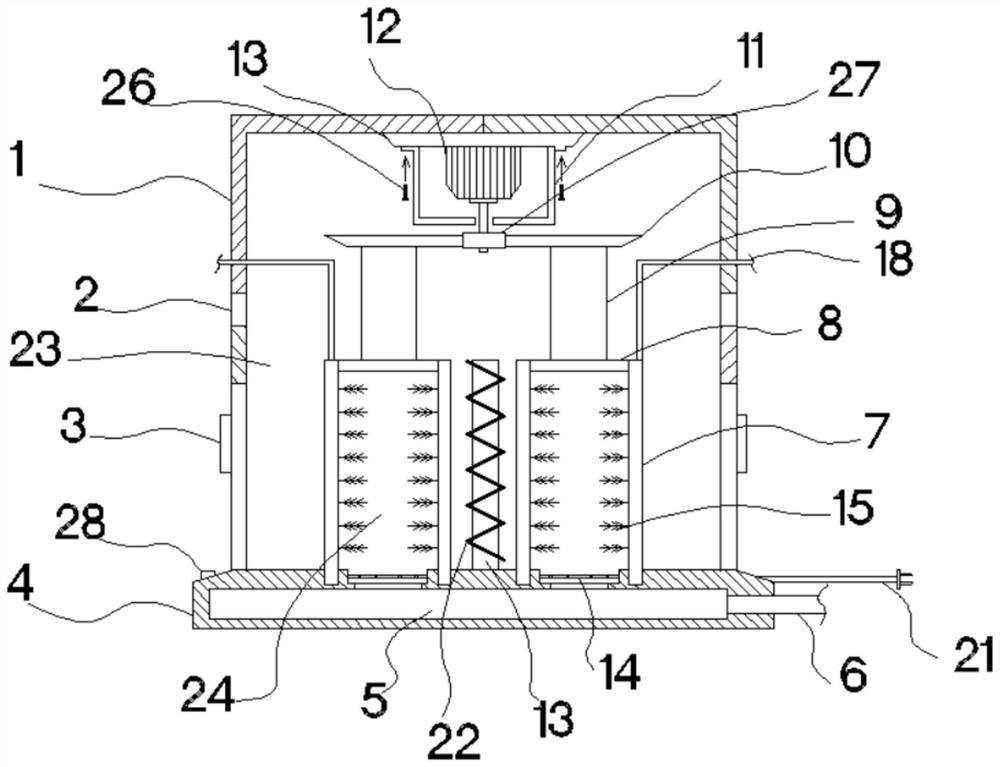

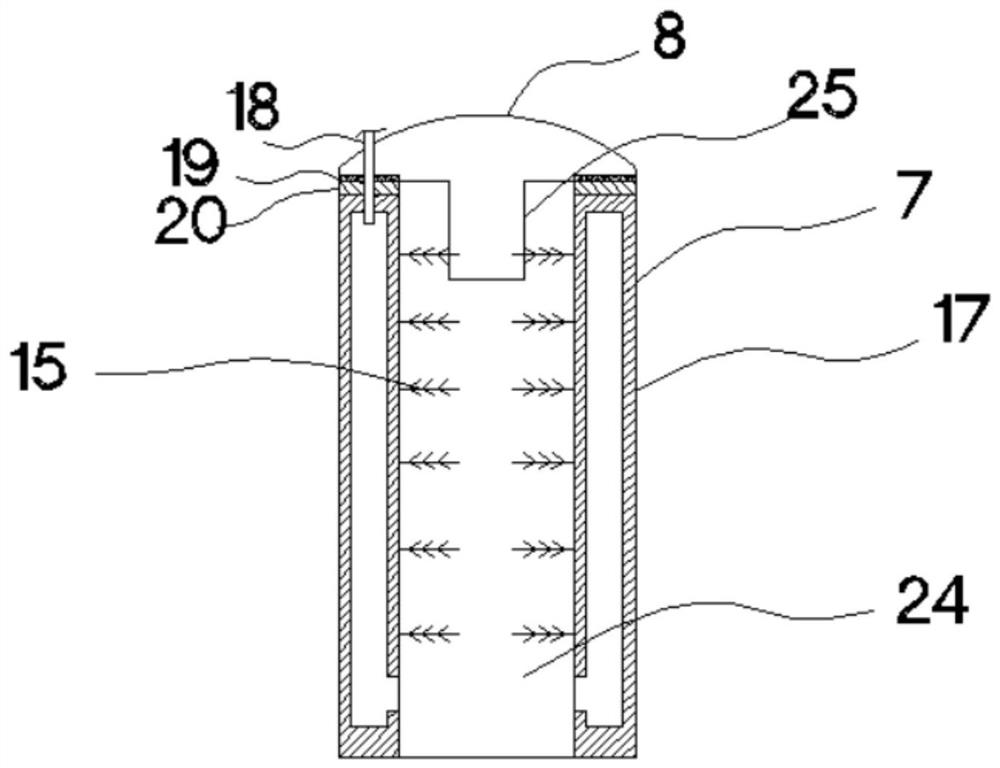

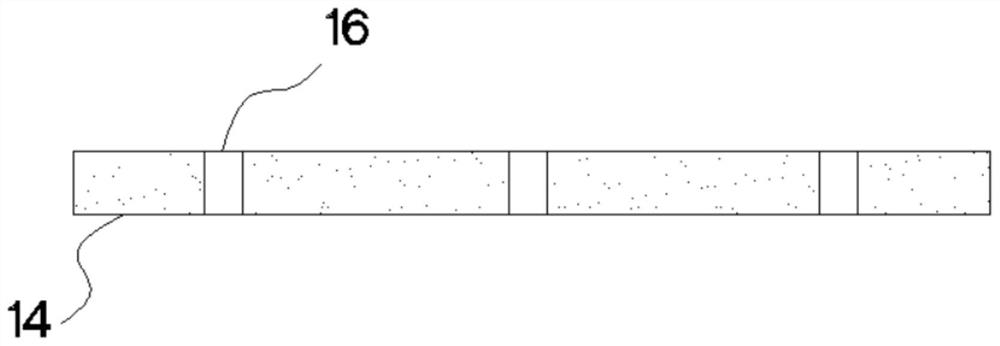

[0034] Such as figure 1 , figure 2 , image 3Shown, comprise a body 1, the bottom of body 1 is provided with a base 4; Body 1 is provided with a washing and drying cavity 23; It is distributed in a circular structure; a circular sleeve 7 is inserted and fixed in the annular slots, a hollow part 24 is provided in the center of the circular sleeve 7, and an annular water storage chamber 17 is arranged in the circular sleeve; A hard scraping hair 15 can be bonded and fixed with strong waterproof glue; the groove bottom of the annular slot is provided with a recess, and an elastic metal plate 14 is welded and fixed in the recess, and some rubber blocks can be placed on the bottom of the elastic metal plate for support, so that the elastic The metal plate is not easy to be pressed down, and the elastic metal plate 14 is provided with a plurality of micropores 16; the opening at the top of the round sleeve 7 is covered by a rubber cover 8, and a magnetic layer 19 is bonded and fi...

Embodiment 2

[0048] Such as figure 1 , figure 2 , image 3 Shown, comprise a body 1, the bottom of body 1 is provided with a base 4; Body 1 is provided with a washing and drying cavity 23; It is distributed in a circular structure; a circular sleeve 7 is inserted and fixed in the annular slots, a hollow part 24 is provided in the center of the circular sleeve 7, and an annular water storage chamber 17 is arranged in the circular sleeve; A hard scraping hair 15 can be bonded and fixed with strong waterproof glue; the groove bottom of the annular slot is provided with a recess, and an elastic metal plate 14 is welded and fixed in the recess, and some rubber blocks can be placed on the bottom of the elastic metal plate for support, so that the elastic The metal plate is not easy to be pressed down, and the elastic metal plate 14 is provided with a plurality of micropores 16; the opening at the top of the round sleeve 7 is covered by a rubber cover 8, and a magnetic layer 19 is bonded and f...

Embodiment 3

[0064] Such as figure 1 , figure 2 , image 3Shown, comprise a body 1, the bottom of body 1 is provided with a base 4; Body 1 is provided with a washing and drying cavity 23; It is distributed in a circular structure; a circular sleeve 7 is inserted and fixed in the annular slots, a hollow part 24 is provided in the center of the circular sleeve 7, and an annular water storage chamber 17 is arranged in the circular sleeve; A hard scraping hair 15 can be bonded and fixed with strong waterproof glue; the groove bottom of the annular slot is provided with a recess, and an elastic metal plate 14 is welded and fixed in the recess, and some rubber blocks can be placed on the bottom of the elastic metal plate for support, so that the elastic The metal plate is not easy to be pressed down, and the elastic metal plate 14 is provided with a plurality of micropores 16; the opening at the top of the round sleeve 7 is covered by a rubber cover 8, and a magnetic layer 19 is bonded and fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com