Photoelectric detector and preparation method thereof

A photodetector and metal electrode technology, applied in the field of photoelectric detection, can solve the problems that the detection accuracy cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

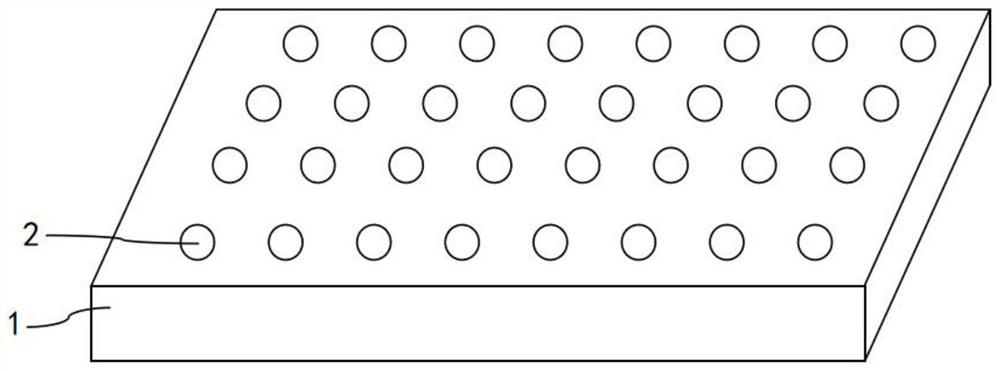

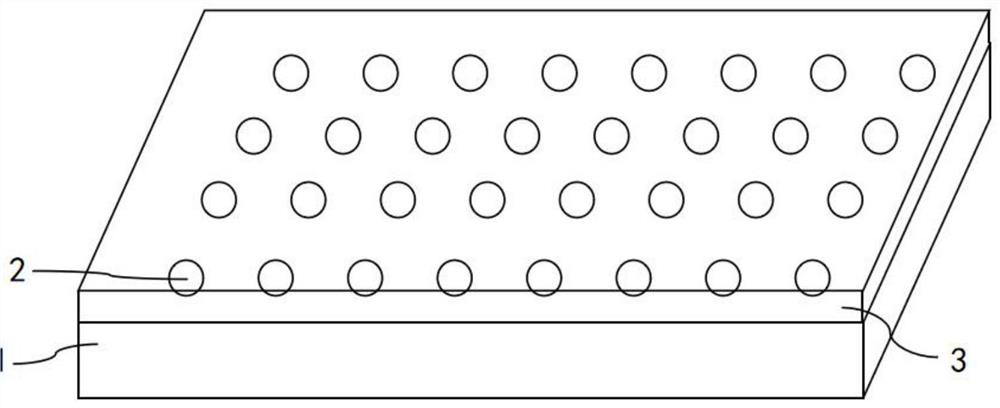

[0056] The photodetector in the present invention includes the following parts: substrate 1, metal nanoparticle layer 2, metal seed layer 3, metal nanowire array 4, insulating material 5, first metal electrode 6 and second metal electrode 7 .

[0057] Such as Figure 1-Figure 8 It is a schematic diagram of the positional relationship among the layers of the photodetector in Example 1 of the present invention during preparation. to combine Figure 1-Figure 8 , the specific preparation process of the photodetector in Embodiment 1 of the present invention is:

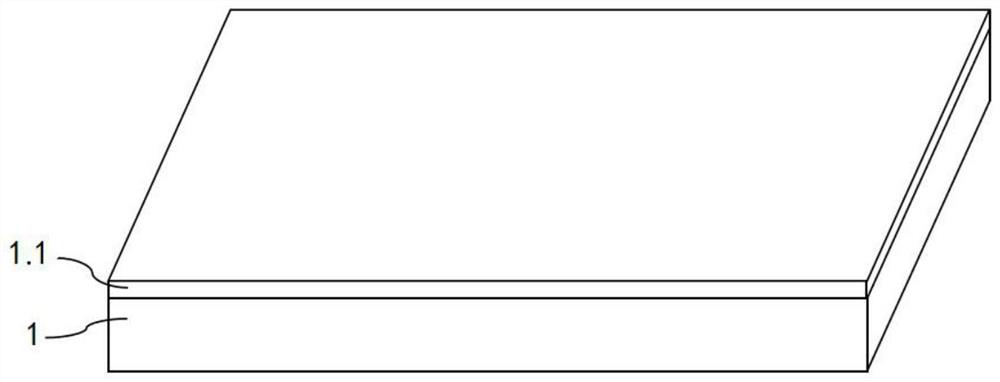

[0058] First, one side of the substrate 1 is polished, and a metal thin film layer 1.1 is deposited on the polished surface, and the metal thin film layer 1.1 completely covers the polished surface of the substrate 1; 1 Metal thin film layer on the polished surface 1.1 Perform rapid annealing treatment; set annealing conditions including annealing temperature, annealing time and annealing gas atmosphere.

[0059] Where...

Embodiment 2

[0068] Single-sided polished P-type silicon with a resistivity of 1-40Ω·cm, a thickness of 725μm, and a crystal orientation of is selected as the substrate 1, and the size of the substrate 1 can be adjusted arbitrarily according to requirements.

[0069] Configure NH 4 F, H 2 A mixed solution of O and HF, where NH 4 F is 40g, H 2 O is 60ml, and HF is 18ml; the silicon wafer is soaked in the prepared solution for 40-60s to remove silicon dioxide formed by oxidation on the surface of the silicon substrate 1 . After the immersion is complete, take out the silicon wafer, rinse it repeatedly with ultrapure water for 3 to 5 times, and then use air to dry the residual liquid on the surface; put the dried silicon wafer into acetone, isopropanol and ultrapure water successively Ultrasonic cleaning is performed for 5-10 minutes, and the residual liquid on the surface needs to be blown dry by air before putting in; finally, the silicon wafer is taken out and blown dry by air; the gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com