A kind of preparation method of iron oxide photoanode with oxalic acid and tetrabutyl titanate acting together

A tetrabutyl titanate, co-acting technology, applied in the field of preparation of iron oxide photoanode, can solve the problems of small hole diffusion length, complicated operation, slow surface reaction rate, etc., to improve photoelectric performance and simple operation steps , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

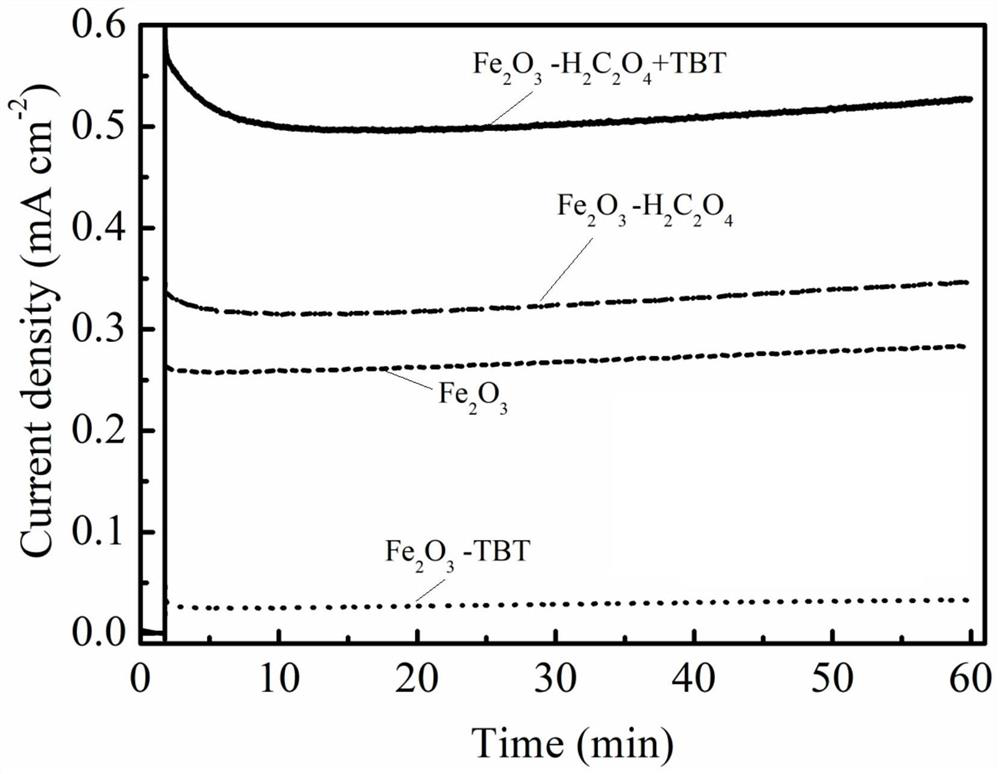

Embodiment 1

[0022] α-Fe 2 o 3 The preparation method of the photoanode is as follows:

[0023] (1) Clean the FTO substrate with detergent, deionized water, acetone and ethanol in an ultrasonic bath for 20 minutes, and then dry it with nitrogen flow. Then standard double electrodes were used, with FTO as the working electrode and platinum sheet as the counter electrode. 4 ·7H 2 O concentration is 36g·L -1 , (NH 4 ) 2 SO 4 The concentration is 22g·L -1 In the electrolytic solution, the Fe film formed on the surface of the FTO substrate was obtained by depositing at a current of 5mA for 180s by the constant current method.

[0024] (2) Wash the Fe film with ethanol, air-dry it, anneal it in argon at 750 °C for 10 min, and cool it naturally to room temperature at a heating rate of 10 °C / min to obtain α-Fe 2 o 3 Photoanode.

Embodiment 2

[0026] Fe 2 o 3 -H 2 C 2 o 4 The preparation method of photoanode comprises the steps:

[0027] (1) is consistent with step (1) in embodiment 1;

[0028] (2) with 50wt% H 2 O in 0.3mol / L oxalic acid ethanol solution soaked at 60°C for 20min to obtain FeC 2 o 4 membrane;

[0029] (3) FeC in step (2) 2 o 4 Membrane is washed with ethanol, after air drying, carries out annealing treatment, and the annealing treatment condition is identical with the step (2) in the specific example 1, namely annealing in argon at 750 DEG C for 10min, heating rate is 10 DEG C / min, naturally cooling to room temperature, Fe 2 o3 -H 2 C 2 o 4 Photoanode.

Embodiment 3

[0031] Fe 2 o 3 -The preparation method of TBT photoanode comprises the steps:

[0032] (1) is consistent with step (1) in embodiment 1;

[0033] (2) Immerse the Fe film prepared in step (1) in the mixed solution of tetrabutyl titanate ethanol solution and concentrated hydrochloric acid, soak for 30s, and perform ultrasonic treatment during the soaking process to ensure that tetrabutyl titanate is evenly attached to the surface of the Fe film. The concentration of tetrabutyl titanate ethanol solution is 0.01mol / L, the mass concentration of concentrated hydrochloric acid is 36%, the volume of ethanol in the mixed solution is 4.95mL, the volume of concentrated HCI is 42 μL, and the volume of tetrabutyl titanate is 17 μL.

[0034] (3) Washing the Fe film after soaking in step (2) with ethanol, after air drying, heat treatment, the heat treatment conditions are the same as the step (2) in Example 1, that is, annealing in argon for 10min at 750°C, The heating rate is 10°C / min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com