High-temperature-resistant testing equipment suitable for silicone sealant

A silicone sealant and testing equipment technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as single high temperature simulation, inability to further simulate the external environment, and failure to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

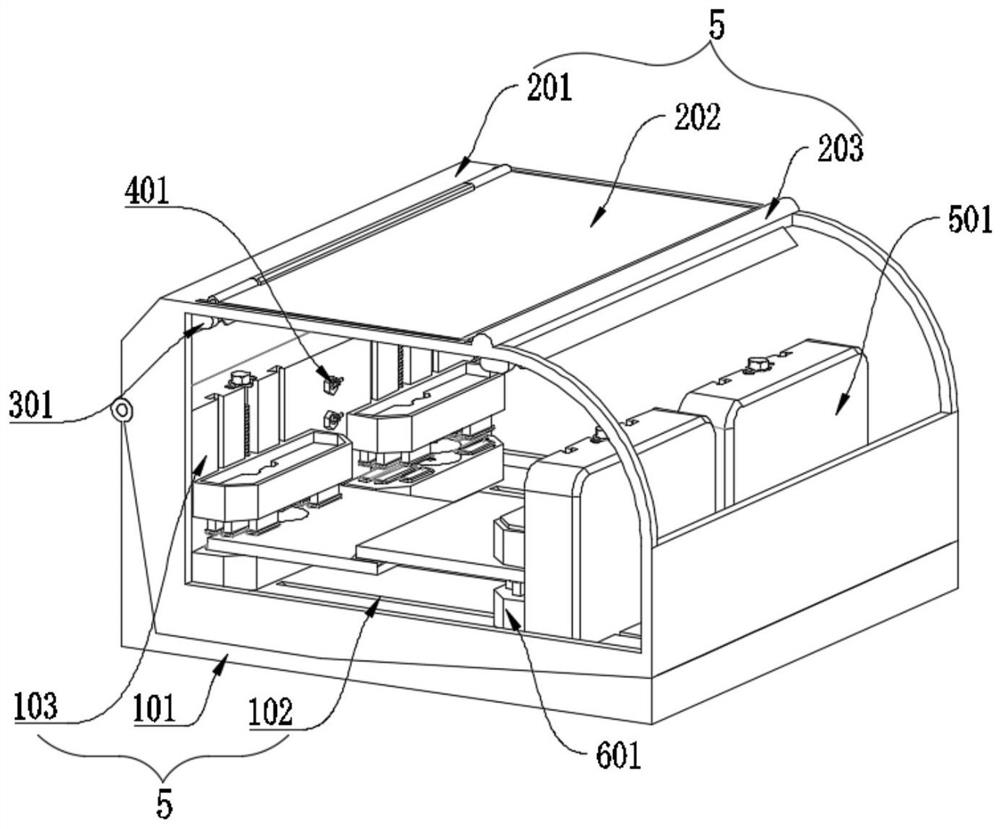

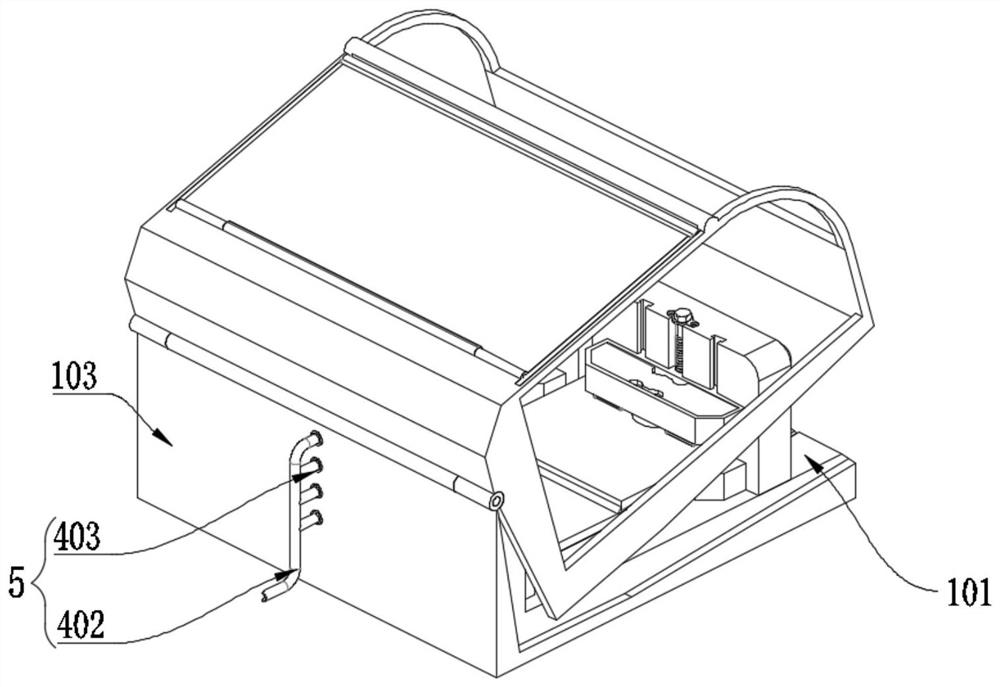

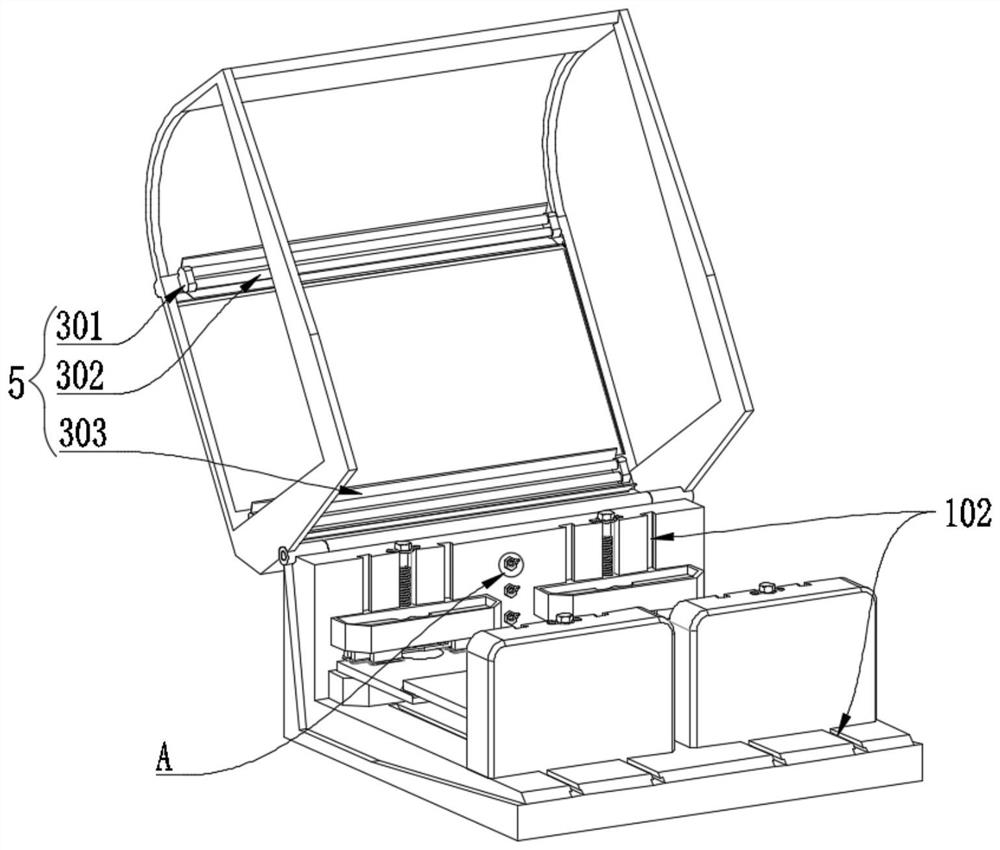

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034]The invention provides a high-temperature-resistant performance testing device suitable for silicone sealants, including an installation structure 1; a protective structure 2 is installed on the installation structure 1, and a heating structure 3 is arranged on the inner end surface of the protective structure 2; the installation structure 1 The middle position is provided with a spraying structure 4, and the sliding structure 5 is installed on the installation structure 1; the clamping structure 6 is installed on the sliding structure 5; The right end is fixed with a mounting riser 103, the mounting riser 103 and the mounting riser 103 are perpendicular to each other, and the mounting plate 101 and the mounting riser 103 form an L-shaped structure, and the mounting plate 101 is provided with four sliding grooves 102, One group of sliding structures 5 is installed on every two groups of sliding grooves 102, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com