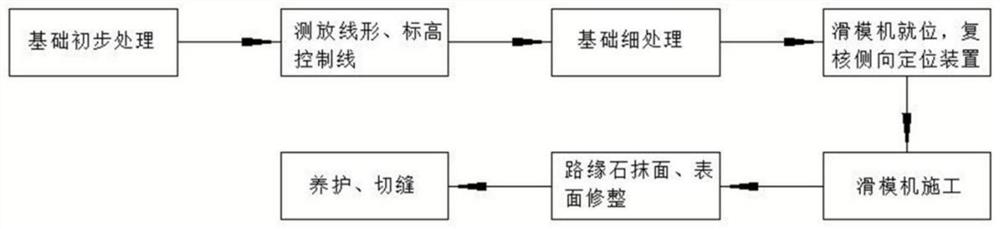

Kerb slip form construction process

A construction technology and curb technology, applied in the field of curb slipform construction technology, can solve the problems of prefabricated site occupation, long construction time, high construction cost, etc., and achieve the effects of improved construction efficiency, reduced construction consumables, and strong anti-collision ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

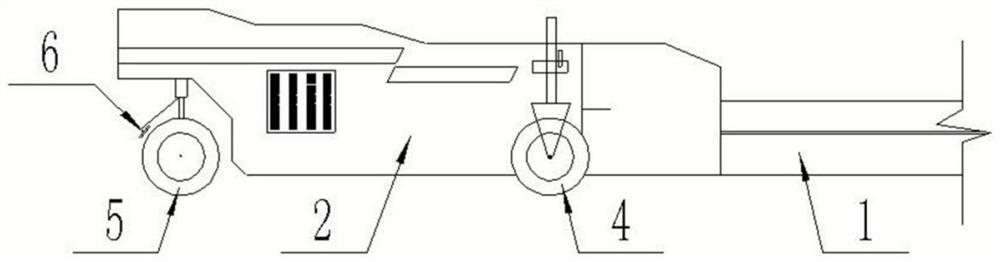

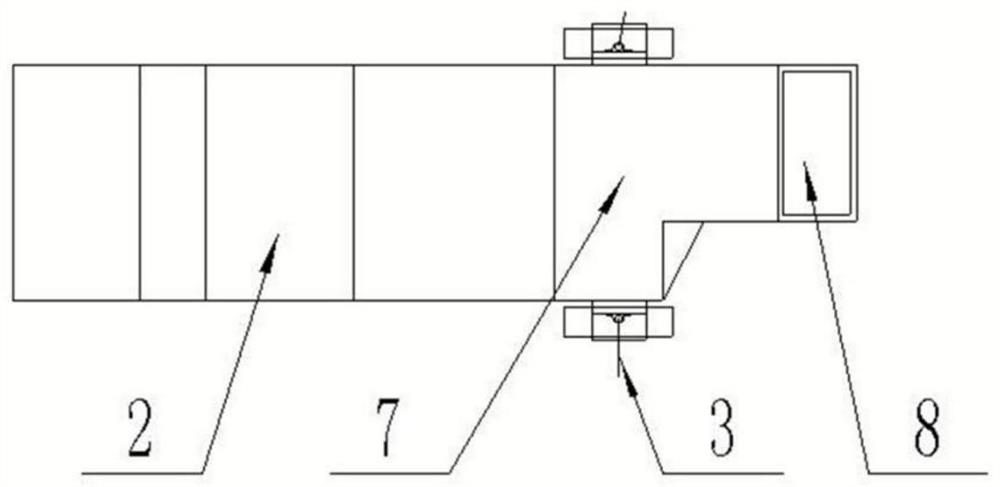

[0036] Such as Figure 1 to Figure 3 Shown, a kind of curb slipform construction technology, concrete steps are:

[0037] S1. Basic preliminary treatment

[0038] First, check the foundation within the walking range of the curb 1 and the sliding form machine 2, process the elevation, and compact it to provide conditions for the measurement and setting out;

[0039] S2, measurement and release alignment, elevation control line

[0040] Measure and set out the alignment and elevation control lines at positions of equal distance outside the curb 1, set a steel bar every 5m in the straight line section, and determine the distance between two adjacent steel bar bars in the arc section according to the radian; After the steel bars are installed, measure and place the elevation control line of the curb 1 on the steel bars, and the elevation of the top of the curb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com