Holocellulose nano composite fiber and preparation method thereof

A nano-composite fiber, cellulose fiber technology, applied in cellulose/protein conjugated man-made filament, fiber processing, spinning solution preparation, etc., can solve the problem of unstable dispersion, decreased physical properties of composite products, and difficult nano-materials. Dispersion evenly and other problems, to achieve the effect of improving dispersion stability, improving fiber quality, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of cellulose nanocrystalline viscose fiber:

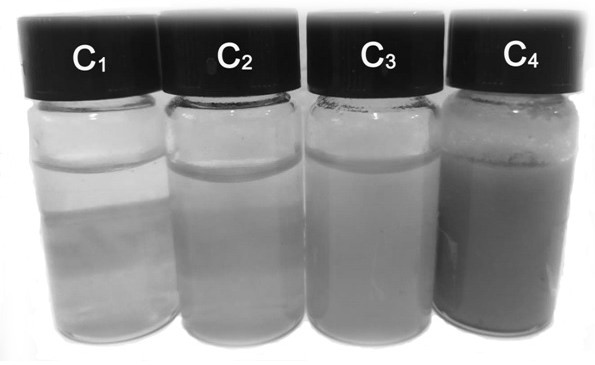

[0029] (1) First, sieve the microcrystalline cellulose derived from wood pulp (greater than 400 mesh) to remove large particles. Mix the sieved microcrystalline cellulose with water and disperse into a suspension with a solid content of 2%.

[0030] (2) Grind the above suspension with a colloid mill for 8 hours. During this period, tighten the stator every 20 minutes until the distance between the rotor and the stator reaches the minimum value.

[0031] (3) Separate the above milled suspension with a centrifuge to obtain a supernatant containing cellulose nanocrystals. The speed of the centrifuge is 4000 rpm. The length of the separated cellulose nanocrystals is 223 ± 100nm, and the diameter It is 29±8nm, and the aspect ratio is 8.

[0032] (4) Concentrating the above cellulose nanocrystal supernatant under vacuum conditions at 60° C. to obtain a supernatant with 5% solid content of cellulose nanocrystals.

[00...

Embodiment 2

[0037] Preparation of cellulose nanocrystalline viscose fiber:

[0038] (1) First, sieve the microcrystalline cellulose derived from wood pulp (greater than 400 mesh) to remove large particles. Mix the sieved microcrystalline cellulose with water and disperse into a suspension with a solid content of 2%.

[0039] (2) Grind the above suspension with a colloid mill for 8 hours. During this period, tighten the stator every 20 minutes until the distance between the rotor and the stator reaches the minimum value.

[0040] (3) Separating the above milled suspension with a centrifuge to obtain a supernatant containing cellulose nanocrystals, the speed of the centrifuge is 3000 rpm, the length of the separated cellulose nanocrystals is 271 ± 124nm, and the diameter is 31±9nm, aspect ratio is 9.

[0041] (4) Concentrating the above cellulose nanocrystal supernatant under vacuum conditions at 60° C. to obtain a supernatant with 5% solid content of cellulose nanocrystals.

[0042] (5)...

Embodiment 3

[0046] Preparation of cellulose nanocrystalline viscose fiber:

[0047] (1) First, sieve the microcrystalline cellulose derived from wood pulp (greater than 400 mesh) to remove large particles. Mix the sieved microcrystalline cellulose with water and disperse into a suspension with a solid content of 2%.

[0048] (2) Grind the above suspension with a colloid mill for 8 hours. During this period, tighten the stator every 20 minutes until the distance between the rotor and the stator reaches the minimum value.

[0049] (3) Separating the above milled suspension with a centrifuge to obtain a supernatant containing cellulose nanocrystals, the speed of the centrifuge is 2000 rpm, the length of the separated cellulose nanocrystals is 366 ± 171nm, and the diameter is 35±9nm, aspect ratio is 10.

[0050] (4) Concentrating the above cellulose nanocrystal supernatant under vacuum conditions at 60° C. to obtain a supernatant with 5% solid content of cellulose nanocrystals.

[0051] (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com