Method for identifying weathering oxidative deterioration degree of coking coal

A technology for oxidative metamorphism and coking coal, applied in coking ovens, material inspection products, instruments, etc., can solve the problems of small data changes, inability to accurately judge coking coal, and inability to determine the time of weathering and oxidative metamorphism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

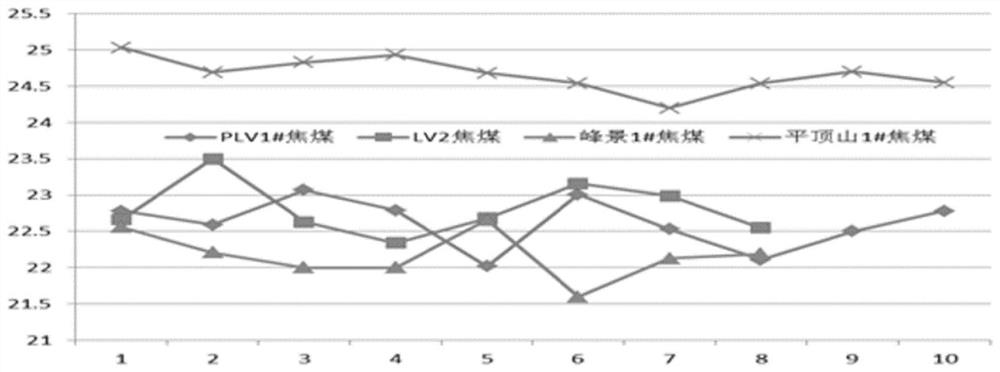

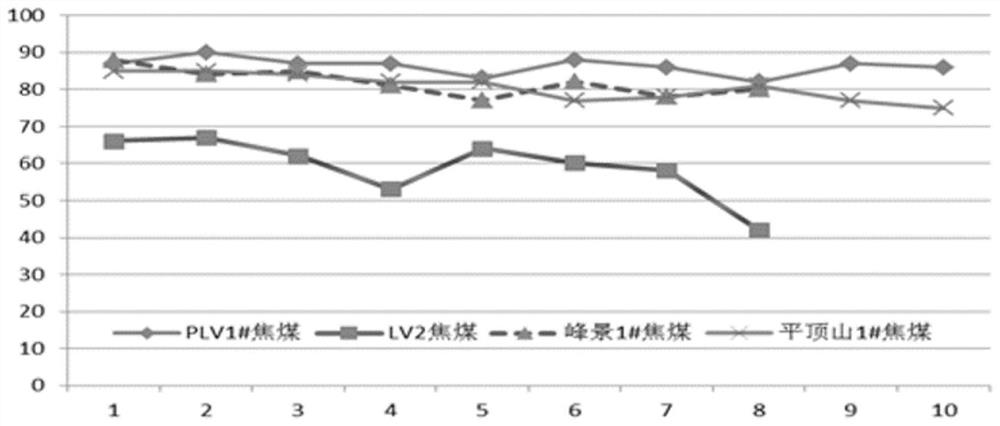

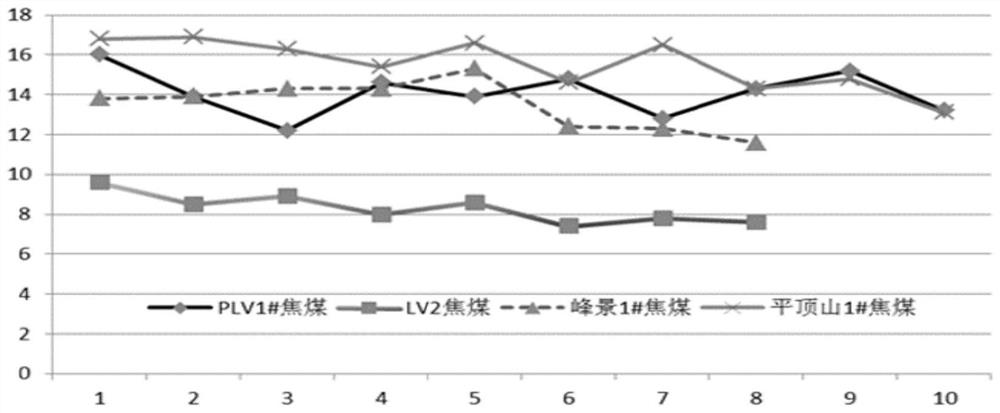

[0081] Australian PLV main coking coal, northern main coking coal, Australian Fengjing main coking coal and Australian LV coking coal were obtained as imported A coking coal, Shanxi coking coal, imported B coking coal, and imported C coking coal, and the coking coal was collected without weathering. The month is recorded as January, and then the coking coal is placed in the open air, and the maximum fluidity of the four groups of coking coal is collected every month (30 days), and the first to eleventh months of its weathering and oxidation are sequentially regarded as month 2 -December, the results are shown in Table 1.

[0082] Table 1 Statistical table of the change of coking coal's maximum fluidity with weathering time

[0083]

[0084]

[0085] According to Table 1, it can be seen that the rate of change of the maximum Gibbs flowability of imported A coking coal, Shanxi coking coal, and imported B coking coal is consistent with the identification method provided in ...

Embodiment 2

[0095] Shaoguan Iron and Steel of Baowu Group used a shipment of Australian "Gon" coking coal spot this year, which is a relatively top-level main coking coal among Australian main coking coals. However, during the blending process of Shaogang, it was found that this coal failed to play the role of the main coking coal. Although the appearance index was good, the coke strength support was weak. The comparison between the typical values of the main coal quality indicators of this coal (the typical value is the value of unweathered oxidative deterioration) and the actual indicators of the ship’s coal is shown in Table 2.

[0096] Among them, in Table 2, Vdaf: volatile matter on a dry ash-free basis, Ad: ash content, St.d: total sulfur on a dry basis, G: cohesion index, Y: maximum thickness of the colloidal layer, X: final shrinkage of the colloidal layer .

[0097] Table 2 Comparison of measured values and typical values of Gon coking coal

[0098]

[0099]

[0100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com