Phase-change energy-storage temperature-regulating foam concrete and preparation method thereof

A technology of foam concrete and phase change energy storage, applied in the field of concrete, can solve the problems of low energy transfer efficiency, large ceramsite particles, leakage of phase change paraffin wax, etc., and achieve improved thermal insulation and energy saving effects, low cost, and fire safety performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

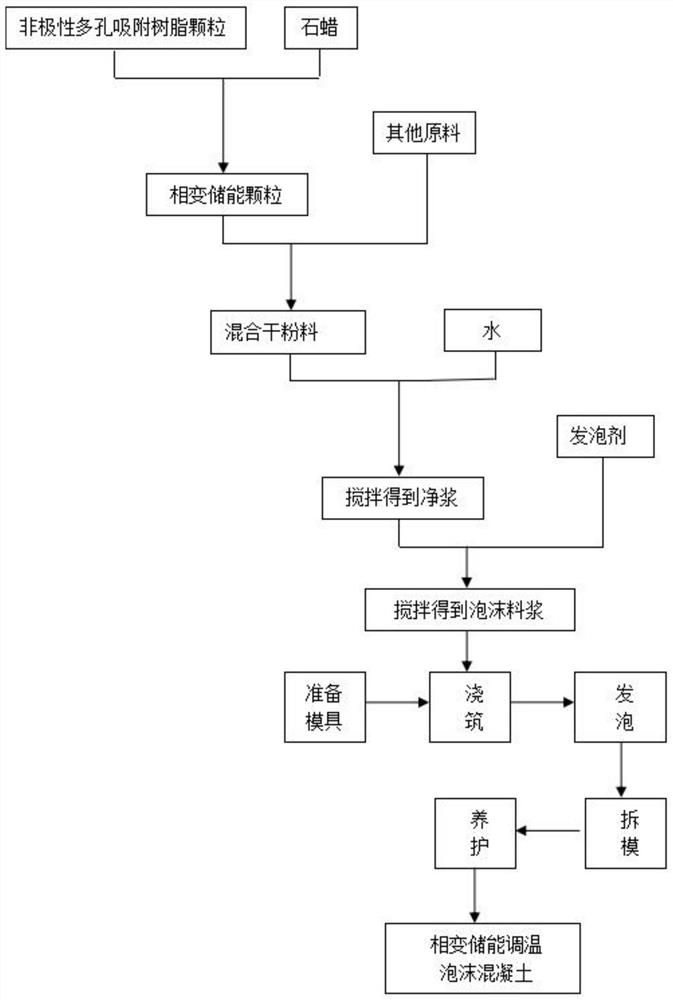

[0037] Embodiment 1, as figure 1 As shown, the phase change energy storage temperature-adjusting foam concrete in this embodiment includes 100 parts of phase change energy storage particles, 800 parts of ordinary silicon cement, 300 parts of filler, 5 parts of accelerator, 5 parts of fiber, and 1 part of coagulation regulator , 3 parts of foam stabilizer, 20 parts of waterproofing agent, 520 parts of water, 50 parts of foaming agent;

[0038] Its preparation method is as follows:

[0039] (1) Make the specific surface area 400~450m 2 / g of non-polar porous adsorption resin particles are dried at 100°C; at 50°C, the paraffin wax with a melting point of 40°C is first melted, and then the melted paraffin wax and the dried non-polar porous adsorption resin particles are Mix and stir at a mass ratio of 1.2:1 until the paraffin is completely absorbed to obtain phase change energy storage particles.

[0040] (2) 800 parts of weight of P.O42.5 ordinary silicate cement, 200 parts of...

Embodiment 2

[0043] Embodiment 2, as figure 1 As shown, the phase change energy storage temperature-adjusting foam concrete in this embodiment includes 300 parts of phase change energy storage particles, 900 parts of ordinary silicon cement, 100 parts of rapid hardening cement, 5 parts of accelerator, 5 parts of fiber, and 0.8 parts of tempering agent. Coagulant, 4 parts of foam stabilizer, 40 parts of waterproofing agent, 600 parts of water, 80 parts of foaming agent;

[0044] Its preparation method is as follows:

[0045] (1) Make the specific surface area 550 ~ 600m 2 The non-polar porous adsorption resin particles per gram were dried at 120°C; at 40°C, the paraffin wax with a melting point of 20°C was first melted, and then the melted paraffin and the dried non-polar porous adsorption resin particles were Mix and stir at a mass ratio of 1.7:1 until the paraffin is completely absorbed to obtain phase-change energy storage particles.

[0046] (2) 900 parts by weight of P·O42.5R ordina...

Embodiment 3

[0049] Embodiment 3, as figure 1 As shown, the phase change energy storage temperature-adjusting foam concrete in this embodiment includes 450 parts of phase change energy storage particles, 950 parts of ordinary silicon cement, 50 parts of rapid hardening cement, 8 parts of accelerator, 10 parts of fiber, and 0.6 parts of tempering agent. Coagulant, 4 parts of foam stabilizer, 30 parts of waterproofing agent, 480 parts of water, 45 parts of foaming agent;

[0050] Its preparation method is as follows:

[0051] (1) Make the specific surface area 550 ~ 600m 2 / g of non-polar porous adsorption resin particles were dried at 120°C; at 45°C, the paraffin wax with a melting point of 30°C was first melted, and then the melted paraffin wax and the dried non-polar porous adsorption resin particles were Mix and stir at a mass ratio of 1.7:1 until the paraffin is completely absorbed to obtain phase-change energy storage particles.

[0052] (2) 950 parts by weight of P·O52.5 ordinary s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com