Returning extensible system used for impact crusher

An impact crusher and material return technology, applied in grain processing and other directions, can solve the problems of low transportation efficiency, inconvenient transportation operations, and cumbersome operations, so as to improve efficiency, ensure work stability and reliable bearing effect, The effect of ensuring compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] For ease of understanding, here in conjunction with accompanying drawing, the concrete structure of the present invention and working mode are further described as follows:

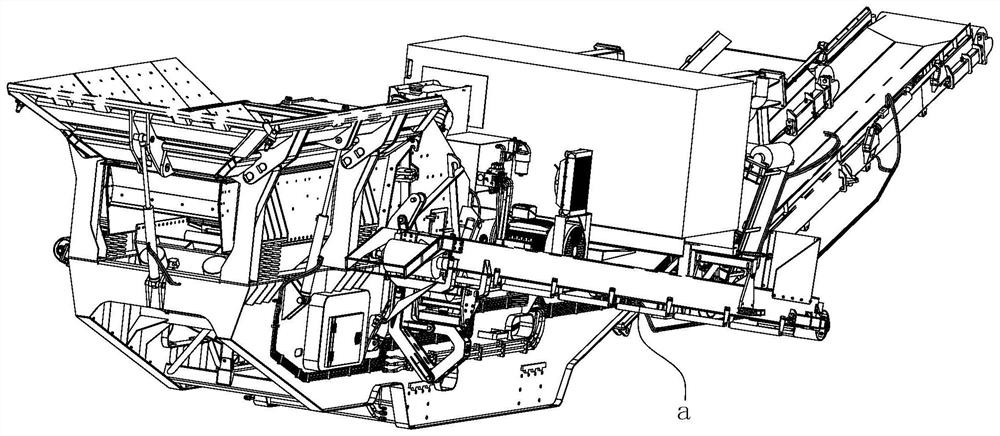

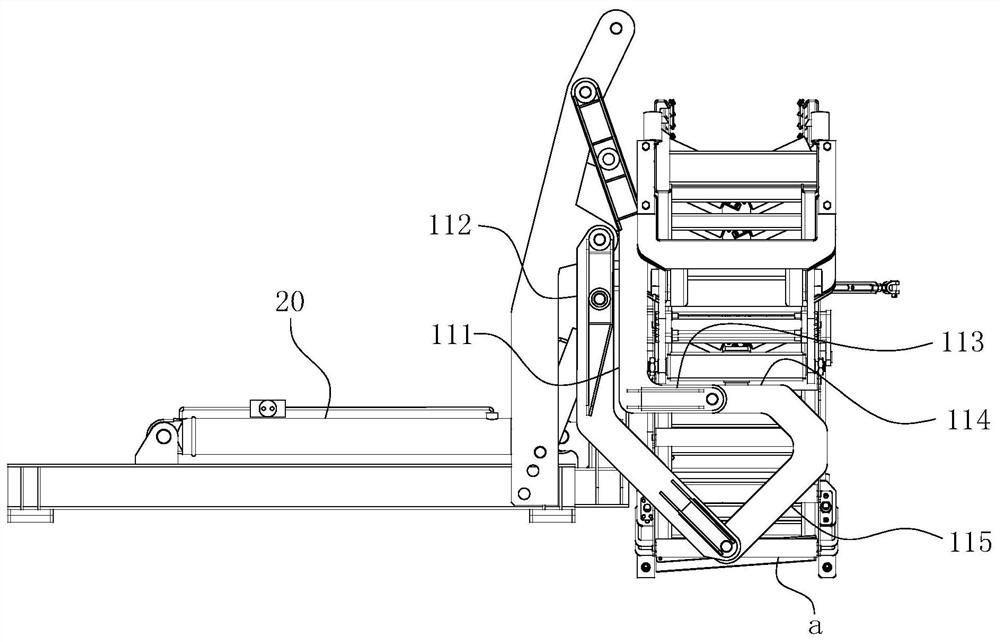

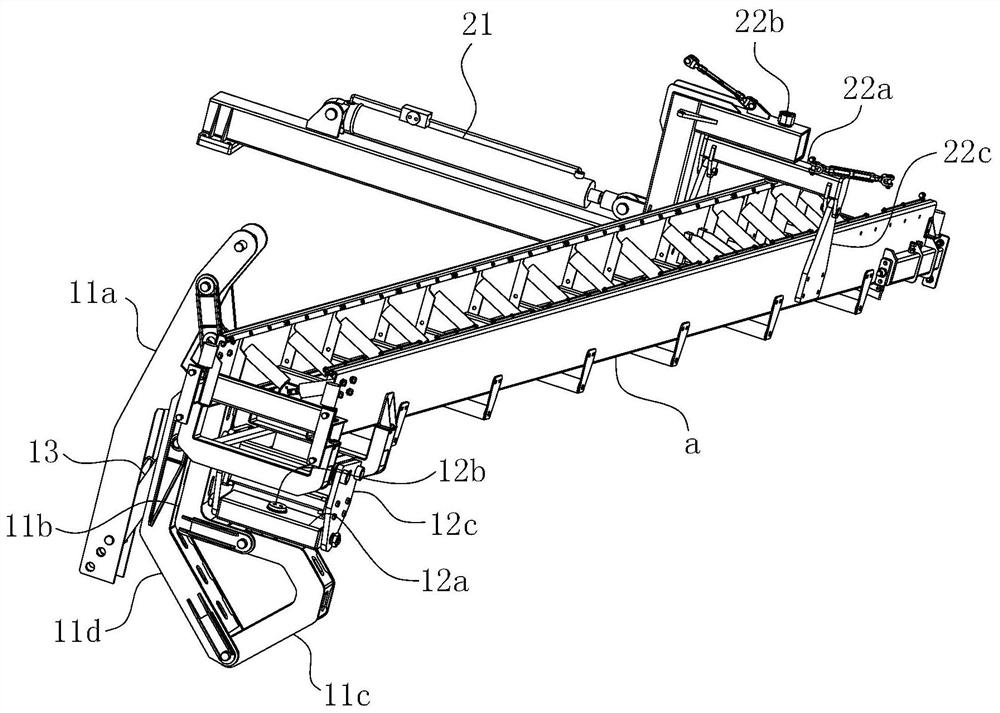

[0045] The specific structure of the present invention refers to Figure 1-10 As shown, its main components include two major parts, the head lifting device 10 and the tail end telescoping device 20, wherein:

[0046] Head Lifting Device 10

[0047] The head-end lifting device 10 is arranged at the head end of the returning material conveying frame a, and its function is to lift the returning material conveying frame to obliquely upward lifting force, and realize timely retraction and reset effect. The specific location is as Figure 1-10 shown.

[0048] The head lifting device 10 is composed of two parts, a four-link jacking assembly 11 and a head support assembly 12 . The four-link jacking assembly 11 is a variant structure based on the traditional four-link, including a first link 11a fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com