Method for detecting content of trace iron in quartz sand

A technology of trace iron and quartz sand, applied in the field of quartz sand treatment, can solve the problems of low accuracy, unfavorable determination of high-purity quartz sand, complicated process, etc., and achieves the effects of reducing measurement cost, accurate and rapid determination, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

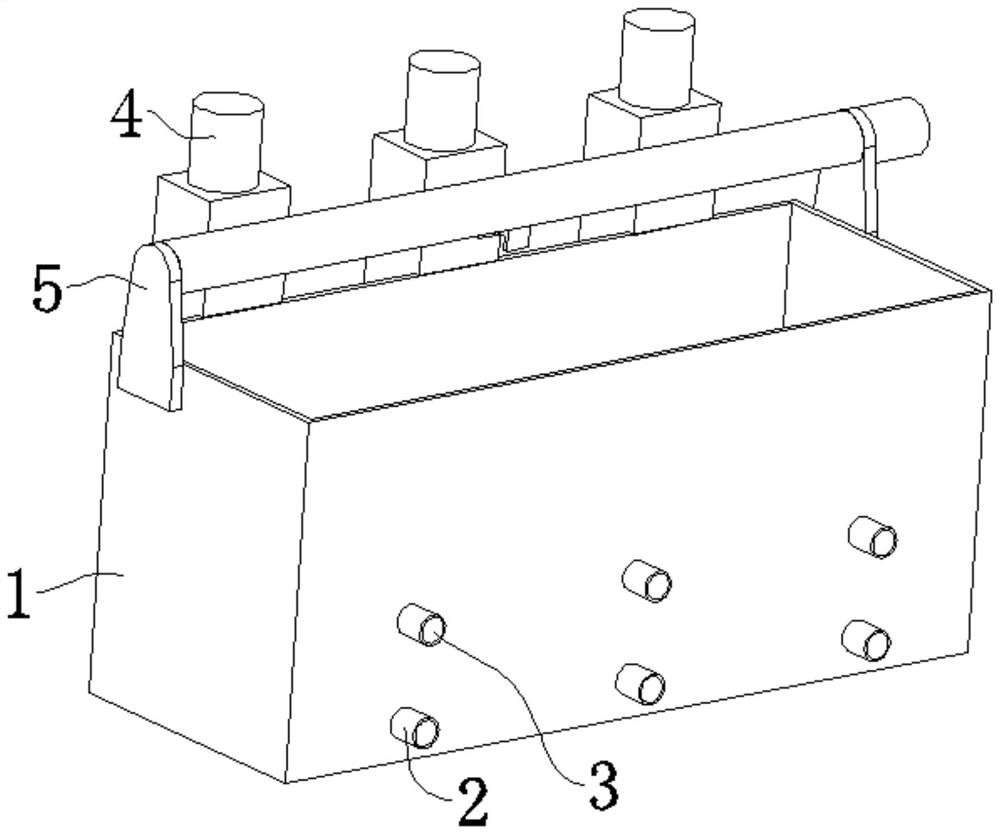

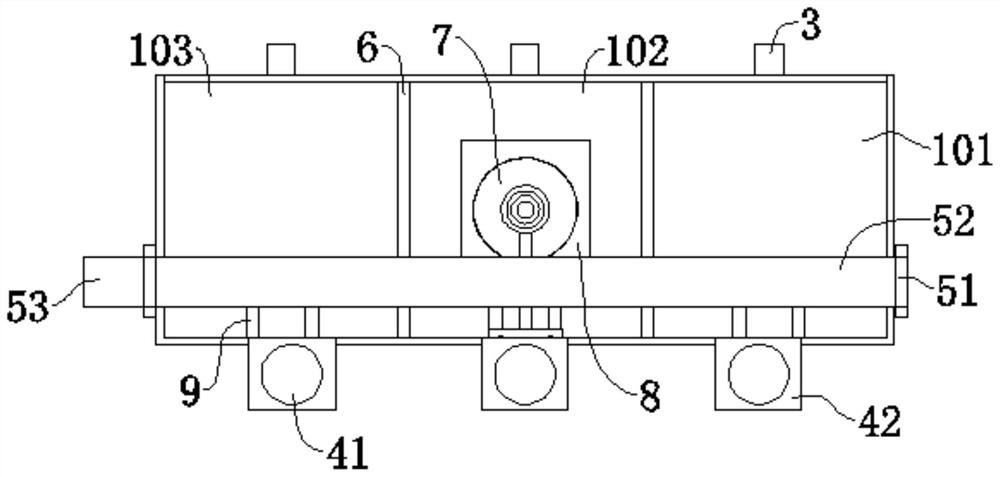

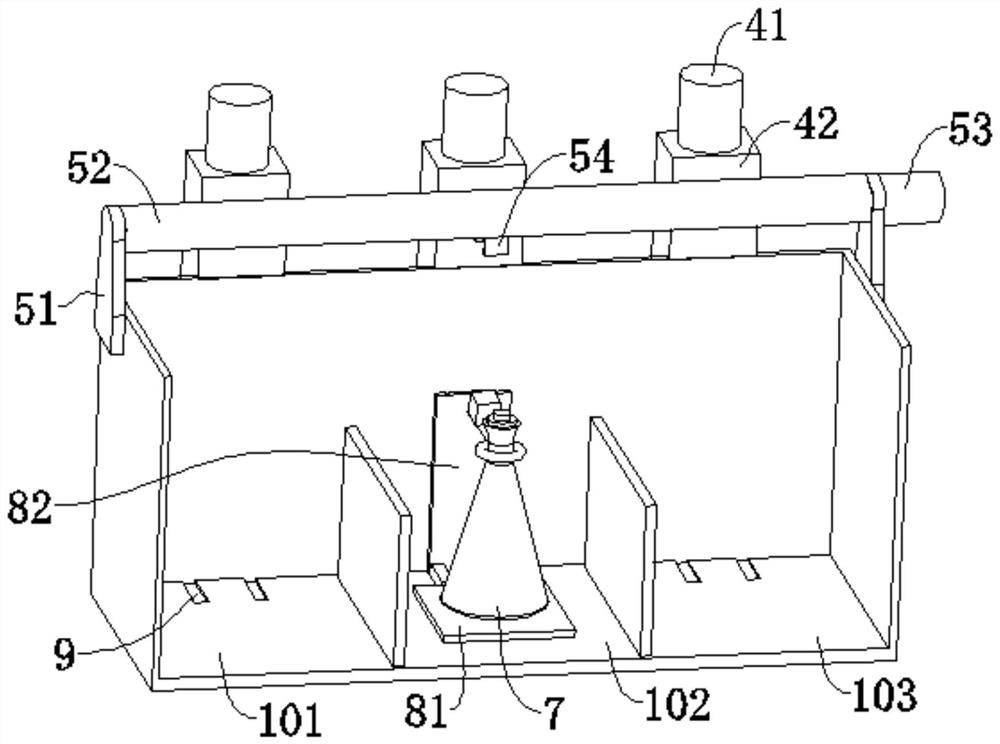

Image

Examples

Embodiment 1

[0043] Embodiment 1: a method for detecting trace iron content in quartz sand, comprising the following steps:

[0044] S1. Prepare the sample to be tested

[0045]Weigh 750 ± 5 mg of siliceous sandstone with an iron content below 0.05%, put it into a 50ml polytetrafluoroethylene bottle 7 resistant to high temperature and high pressure, add 5ml of concentrated hydrofluoric acid, tighten the bottle cap and put it in a microwave oven. After the siliceous sandstone is completely decomposed (about 25-30 minutes), it is taken out, and the sample to be tested is obtained after being cooled by a water cooling device.

[0046] Further preferably, the polytetrafluoroethylene bottle 7 can be a material bottle of various geometric shapes such as an Erlenmeyer flask and a flask.

[0047] Further preferably, during the heating process of the microwave oven, a medium-low fire is selected, and the emitted microwave intensity is 750W×33%.

[0048] S2, Fe reagent 2 preset

[0049] Preparati...

Embodiment 2

[0068] Embodiment 2: A method for detecting trace iron content in quartz sand. The difference from Embodiment 1 is that the siliceous sandstone weighs 380±5 mg, and the iron content is between 0.05-0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com