An assembled pocket grass-planting concrete prefabricated component and construction method

A technology of prefabricated components and construction methods, applied in botany equipment and methods, manufacturing tools, site preparation methods, etc., can solve the problems of difficult on-site preparation of grass-planted concrete, easy erosion of surface soil, and unstable structure, etc., and achieve relief Difficulty in later maintenance, convenient construction, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

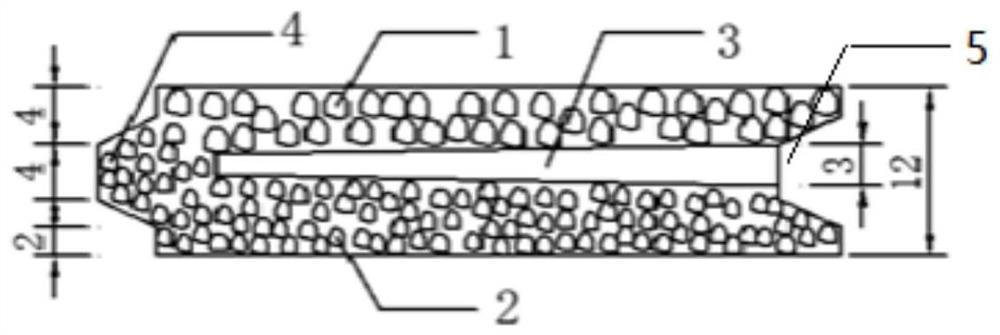

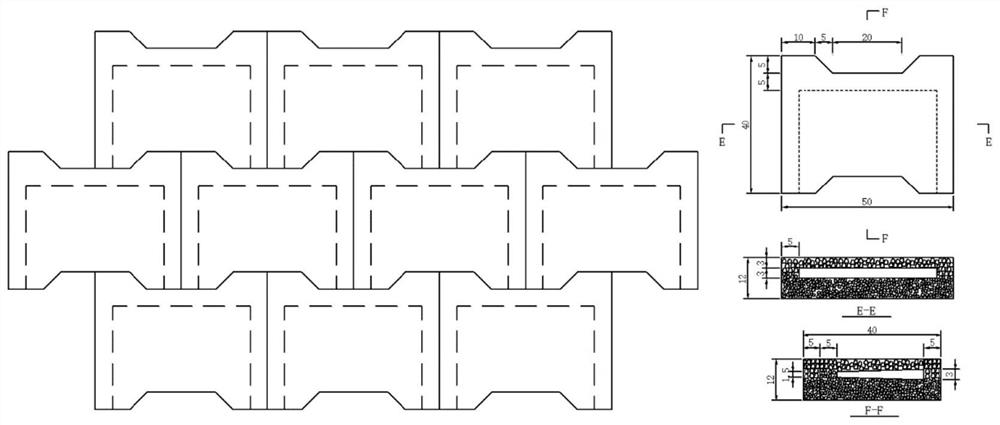

[0045] (1) An I-shaped prefabricated pocket grass-planting concrete prefabricated component is composed:

[0046] The upper layer of grass-planted concrete aggregate is made of ceramsite thermal insulation, moisturizing and heat-insulating material, the lower layer of grass-planted concrete aggregate is selected from artificial crushed stone, and the grass seeds filled in the planting bag are long fibrous vetiver grass seeds.

[0047]According to the root growth law and engineering strength requirements, the total thickness of the prefabricated pocket grass-planting concrete is 10-12cm, which is divided into 3 layers. 4-8cm.

[0048] The porosity of the grass-planted concrete on the upper layer is controlled at 30%, using 25-30mm ceramsite, and the porosity of the lower layer concrete is controlled at 20-25%, using artificial gravel of 15-25mm. The mix ratio of the grass-planted concrete on the upper layer is prepared from the following raw materials in parts by weight: 974 p...

Embodiment 2

[0060] (1) An I-shaped prefabricated pocket grass-planting concrete prefabricated component is composed:

[0061] The upper layer of grass-planting concrete aggregate is made of coral stone thermal insulation, moisture-proof and heat-insulating material, and the lower layer of grass-planted concrete aggregate is selected from pebble.

[0062] According to the root growth law and engineering strength requirements, the total thickness of the prefabricated pocket grass-planting concrete is 10-12cm, which is divided into 3 layers. 4-8cm.

[0063] The porosity of the grass-planted concrete on the upper layer is controlled at 30%, using 25-30mm coral stone, and the porosity of the lower layer concrete is controlled at 20-25%, using 15-25mm pebbles. The mix ratio of the grass-planted concrete on the upper layer is prepared from the following raw materials in parts by weight: 974 parts of coarse aggregate, 68.8 parts of cement, 68.8 parts of sand, 0.13 parts of naphthalene-based supe...

Embodiment 3

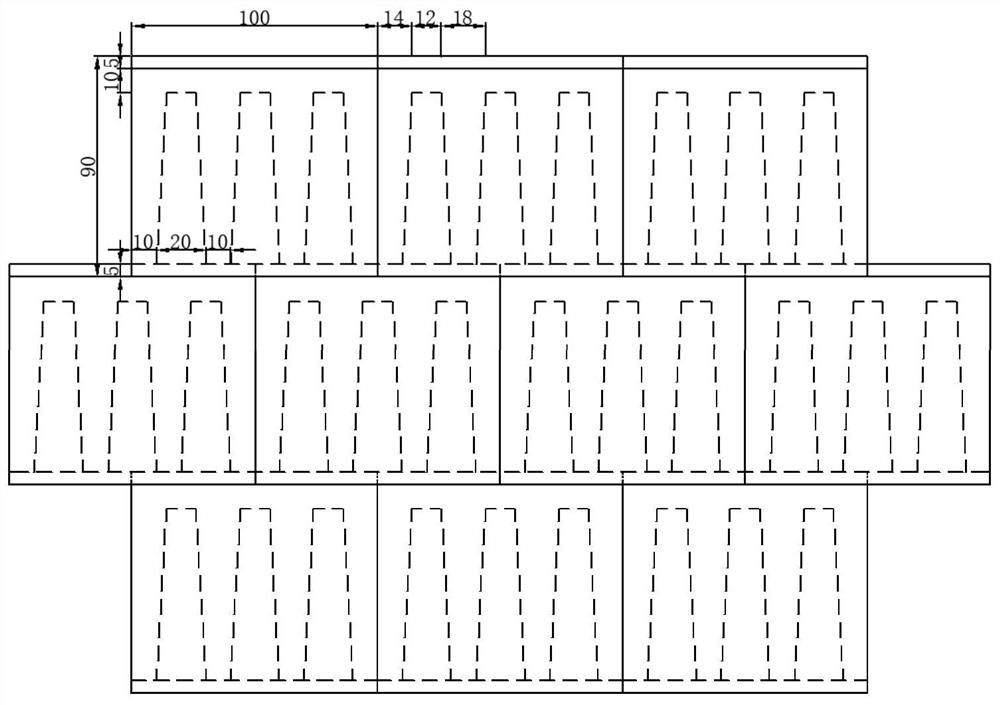

[0075] (1) A rectangular prefabricated pocket grass-planting concrete prefabricated component consists of:

[0076] The upper layer of grass-planted concrete aggregate is made of ceramsite thermal insulation, moisturizing and heat-insulating material, and different ecological color pigments are added.

[0077] According to the root growth law and engineering strength requirements, the total thickness of the prefabricated pocket grass-planting concrete is 10-12cm, which is divided into 3 layers. 4-8cm.

[0078] The porosity of the grass-planted concrete on the upper layer is controlled at 30%, using 25-30mm ceramsite, and the porosity of the lower layer concrete is controlled at 20-25%, using artificial gravel of 15-25mm. The mix ratio of the grass-planted concrete on the upper layer is prepared from the following raw materials in parts by weight: 974 parts of coarse aggregate, 68.8 parts of cement, 68.8 parts of sand, 0.13 parts of naphthalene-based superplasticizer, 3.4 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com