Center-rod-adjustable high-temperature and high-pressure dyeing machine and using method thereof

A high-temperature, high-pressure and adjustable technology, applied in textile processing machine accessories, textile and papermaking, textile material processing, etc. Reduce the amount of dye liquor used, easy to operate, and the effect of uniform dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

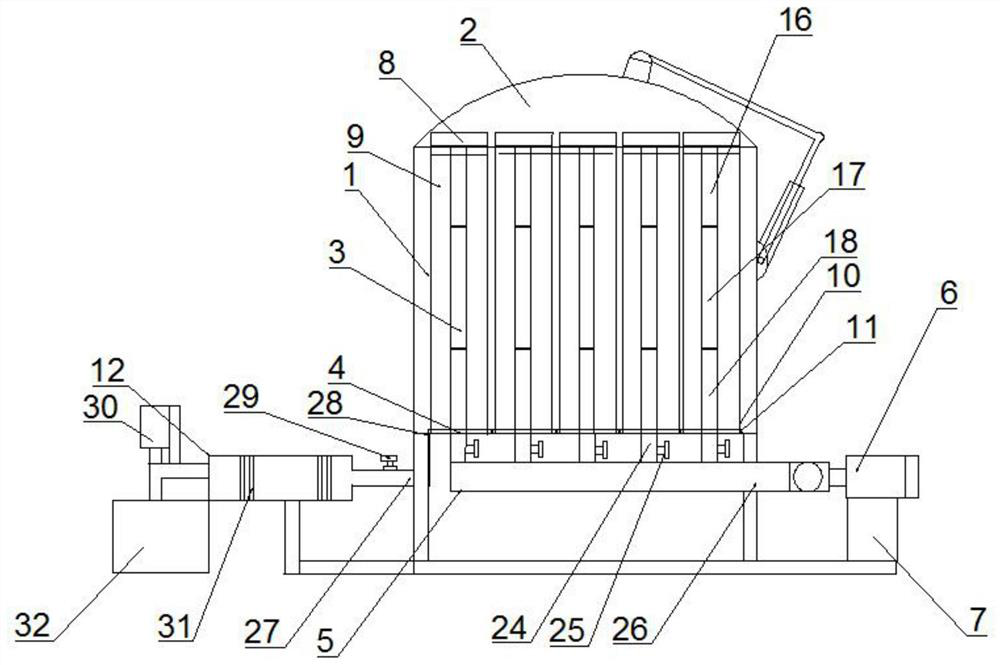

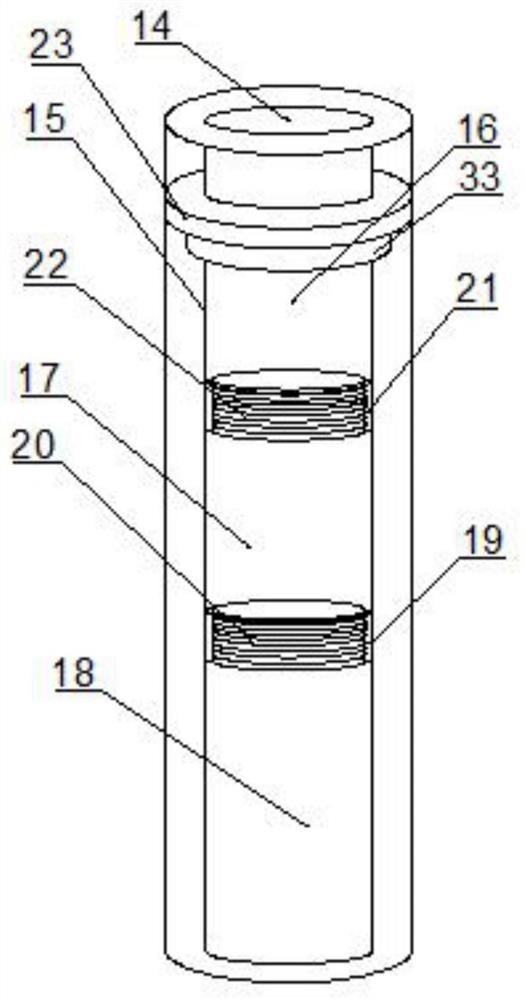

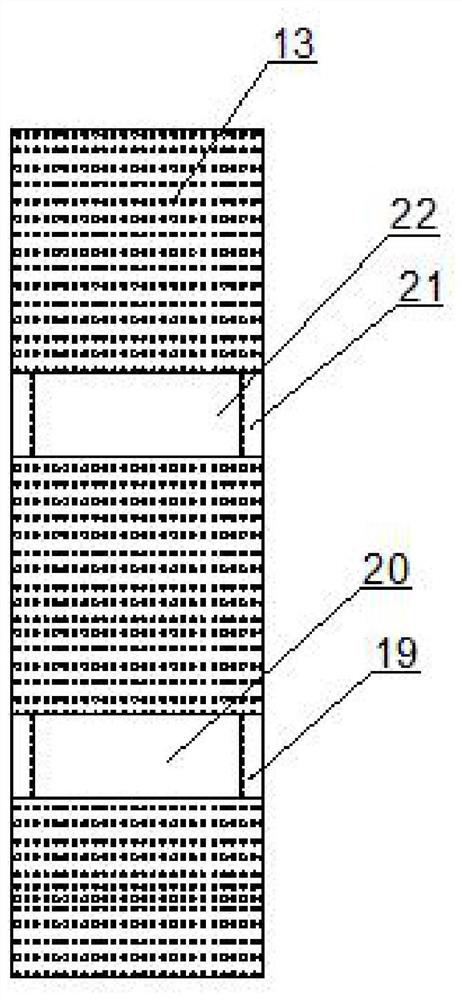

[0028]A high-temperature and high-pressure dyeing machine with an adjustable central rod, including a high-pressure cylinder 1 and a cylinder head 2, a plurality of adjustable dyeing cylinders 3 are installed in the high-pressure cylinder 1, and the adjustable dyeing cylinders 3 are welded to the bottom of the high-pressure cylinder 1 On the end face 10, a plurality of circulation holes 4 are arranged on the bottom end surface 10, and the circulation holes 4 communicate with the inner hole of the adjusting dyeing cylinder 3, and the lower ends of the plurality of circulation holes 4 are connected with the circulation device 5, so that The circulation device 5 is connected to the circulation pump 6, the circulation pump 6 is fixed on the support 7 at the lower end of the high-pressure cylinder 1, the cylinder head 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com