Aluminosilicate glass and strengthening method thereof

A kind of aluminosilicate glass and glass technology, which is applied in the field of glass preparation, can solve the problems of reduced crack growth resistance, low glass deformation resistance, and damage to electronic components, etc., and achieves small deformation, small thermal expansion coefficient, and enhanced mechanical strength. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

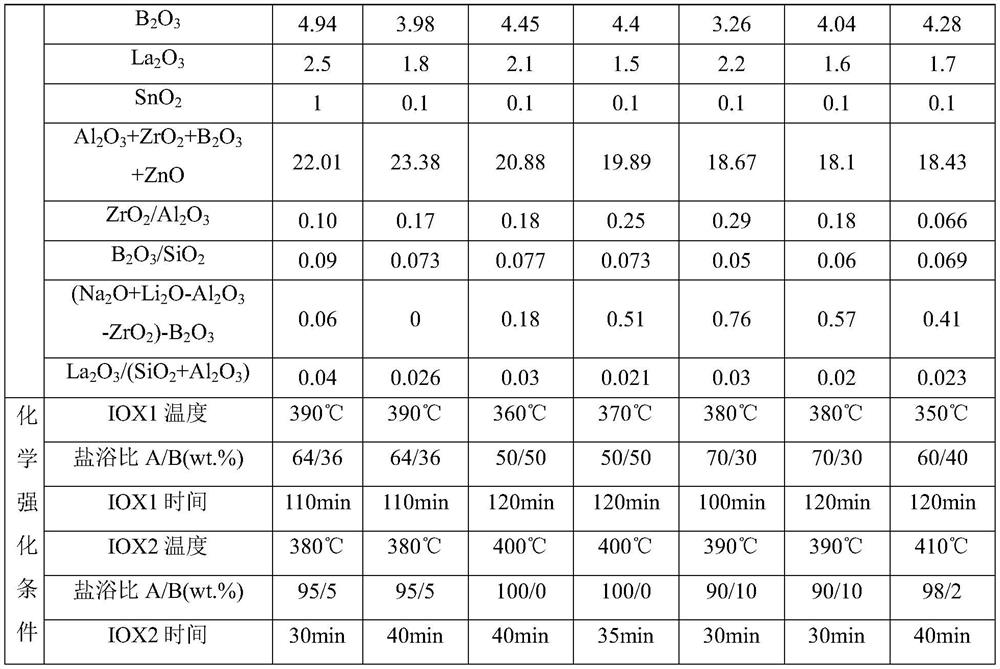

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0032] The system and composition of the glass are the main factors that determine the strength of the glass itself, while the strength, deformation resistance and impact resistance of ordinary soda-lime glass are inferior to aluminosilicate glass. And other parameters are not as good as aluminosilicate glass, so the aluminosilicate glass system is selected and optimized on this basis to improve performance. Chemical strengthening can improve the strength of glass, using low-temperature ion exchange, that is, placing the glass in a molten salt solution (potassium and sodium salts, such as KNO at a temperature lower than the strain point of the glass) 3 、NaNO 3 ), the small ions in the glass are replaced with the large ions in the salt bath, so that the surface of the glass is in a compressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Surface compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com