Universal preparation method for synthesizing carbon-coated nickel metal compound with various morphologies

A metal compound and carbon-coated technology, which is applied in the application field of anode materials for sodium-ion batteries, can solve problems such as lengthy operation steps, material waste, and low conversion efficiency, and achieve abundant raw material reserves, good rate performance, and high specific capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

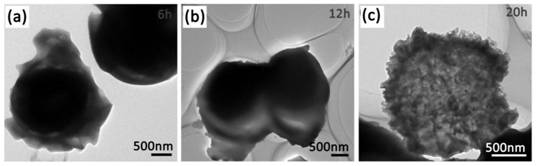

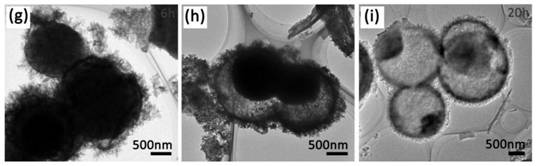

[0015] (1) Dissolving benzenetricarboxylic acid (0.15g), nickel nitrate hexahydrate (0.432g) and polyvinylpyrrolidone (1.033g) into the mixed solvent according to a certain quantitative ratio (V N,N-二甲基甲酰胺 :V 蒸馏水 =1:1), mixed evenly, transferred to a hydrothermal kettle, reacted in a thermostat at 160°C for 6 hours, cooled, washed and dried to obtain Ni-MOFs solid spheres.

[0016] (2) Put the Ni-MOFs spheres obtained in step (1) into a tube furnace, pass in an inert gas, and calcinate at 500 °C for 2 h to obtain a black powder, which is a carbon-coated NiO solid sphere (NiO@ C).

Embodiment 2

[0018] (1) Dissolving benzenetricarboxylic acid (0.15g), nickel nitrate hexahydrate (0.432g) and polyvinylpyrrolidone (1.033g) into the mixed solvent according to a certain quantitative ratio (V N,N-二甲基甲酰胺 :V 蒸馏水 =1:1), mixed evenly, transferred to a hydrothermal kettle, reacted in a thermostat at 160°C for 12 hours, cooled, washed and dried to obtain Ni-MOFs core-shell spheres.

[0019] (2) Place the Ni-MOFs spheres obtained in step (1) into a tube furnace, pass in an inert gas, and calcinate at 500°C for 2 hours to obtain a black powder, which is a carbon-coated NiO core-shell sphere (NiO @C).

Embodiment 3

[0021] (1) Dissolving benzenetricarboxylic acid (0.15g), nickel nitrate hexahydrate (0.432g) and polyvinylpyrrolidone (1.033g) into the mixed solvent according to a certain quantitative ratio (V N,N-二甲基甲酰胺 :V 蒸馏水 =1:1), mixed evenly, transferred to a hydrothermal kettle, reacted in a thermostat at 160°C for 20h, cooled, washed and dried to obtain Ni-MOFs hollow spheres.

[0022] (2) Put the Ni-MOFs spheres obtained in step (1) into a tube furnace, pass in an inert gas, and calcinate at 500 °C for 2 h to obtain a black powder, which is a carbon-coated NiO hollow sphere (NiO@ C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com