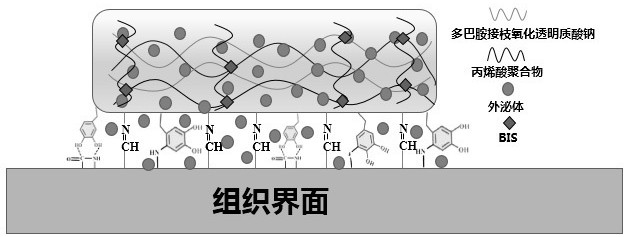

Adhesive healing-promoting hemostatic sponge and preparation method thereof

A technology of hemostatic sponge and oxidized hyaluronic acid, which is applied in the fields of medical formula, medical science, absorbent pads, etc., can solve the problems of inability to promote wound healing, limited embolization effect, poor mechanical strength, etc., and achieve long-term high-efficiency promotion of healing, Effect of preventing displacement and good affinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 Dopamine grafted oxidized sodium hyaluronate with a mass fraction of 2.5% (the degree of oxidation is 50%, the grafting rate of dopamine is 7.5%, and the molecular weight is 37-56KDa), 0.75% exosomes, 20% acrylic acid, Add 0.015% N, N'-methylene bisacrylamide into purified water, stir at 100-200rpm until completely dissolved, add dropwise sodium hydroxide solution to neutrality, add 0.6% ammonium persulfate, 0.3% hydrogen sulfite Sodium, stirred evenly at 100-200rpm, reacted at 60°C for 1.5h under the protection of nitrogen to obtain a gel-like product. The gel product is placed in purified water 10 times its own weight after swelling, and is dialyzed for 24 hours under stirring at 50-100 rpm (purified water is replaced once every 8 hours, a total of 3 times of dialyzing), and the condensation of redox initiators can be removed. Gel-like product. The gel-like product after dialysis is placed in a mold, placed in a freeze dryer at -50°C for 6 hours, and vacuum...

Embodiment 2

[0048] Example 2 Dopamine grafted oxidized sodium hyaluronate with a mass fraction of 3.5% (the degree of oxidation is 40%, the grafting rate of dopamine is 5%, and the molecular weight is 8-10KDa), 0.5% exosomes, 15% acrylic acid, Add 0.01% N, N'-methylenebisacrylamide into purified water, stir at 100-200rpm until completely dissolved, add disodium hydrogen phosphate solution to neutrality, add 0.4% ammonium persulfate, 0.2% sulfurous acid Sodium hydrogen, stirred evenly at 100-200rpm, reacted at 60°C for 1.5h under nitrogen protection, to obtain a gel-like product. The gel product is placed in purified water 10 times its own weight after swelling, and is dialyzed for 24 hours under stirring at 50-100 rpm (purified water is replaced once every 8 hours, a total of 3 times of dialyzing), and the condensation of redox initiators can be removed. Gel-like product. The gel-like product after dialysis is placed in a mold, placed in a freeze dryer at -50°C for 6 hours, and vacuumed ...

Embodiment 3

[0049] Example 3 Dopamine grafted oxidized sodium hyaluronate with a mass fraction of 1.5% (the degree of oxidation is 60%, the grafting rate of dopamine is 10%, and the molecular weight is 60-80KDa), 1.0% exosomes, 25% acrylic acid, Add 0.02% N, N'-methylenebisacrylamide into purified water, stir at 100-200rpm until completely dissolved, add dropwise sodium bicarbonate solution until neutral, add 0.7% ammonium persulfate, 0.3% bisulfite Sodium, stirred evenly at 100-200rpm, reacted at 60°C for 1.5h under the protection of nitrogen to obtain a gel-like product. The gel product is placed in purified water 10 times its own weight after swelling, and is dialyzed for 24 hours under stirring at 50-100 rpm (purified water is replaced once every 8 hours, a total of 3 times of dialyzing), and the condensation of redox initiators can be removed. Gel-like product. The gel-like product after dialysis is placed in a mold, placed in a freeze dryer at -50°C for 6 hours, and vacuumed after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com