Thermosetting resin composition, coating material for pre-coated metal, cured product, and laminate

A resin composition, thermosetting technology, applied in synthetic resin layered products, coatings, devices for applying liquid to surfaces, etc., can solve problems such as insufficient performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0135] Hereinafter, the present invention will be more specifically described based on examples, but the present invention is not limited by these examples.

[0136] [Material]

[0137] In the following examples and comparative examples, the compositions (coating materials) and raw materials used for the preparation of the coating materials, and the covered bodies (substrates) used for coating the compositions are as follows.

[0138]

[0139] "Polyester Resin with Hydroxyl Group"

[0140] ・(A-1) "Almatex P646" manufactured by Mitsui Chemicals Co., Ltd.

[0141] Solvent: mixed solvent of SOLVESSO #100 (manufactured by ExxonMobil Chemical Co., SP value=18.0) / methyl isobutyl ketone (SP value=17.2)=9 / 1

[0142] Solid content: 60%

[0143] Weight average molecular weight: 51,000

[0144] Hydroxyl value: 52mgKOH / g

[0145] ・(A-2) "Almatex P646SB" manufactured by Mitsui Chemicals Co., Ltd.

[0146] Solvent: sec-butanol (SP value = 22.1)

[0147] Solid content: 60%

[0148]...

Embodiment A1~29

[0253] [Examples A1-29, Comparative Examples A1-20]

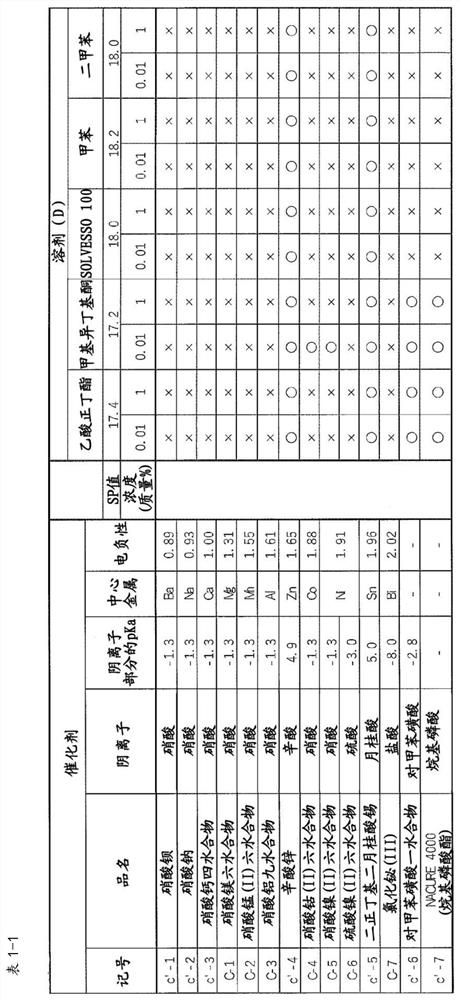

[0254] By mixing resin (A) or (a) having a hydroxyl group, melamine resin (B), Lewis acid catalyst (C) or other catalyst (c') and solvent (D) in the ratio shown in Tables 2-4, Thus, a composition (coating material) was prepared and evaluated.

[0255] After the obtained composition was coated on a steel plate (150 mm x 70 mm x thickness 0.8 mm) using a bar coater so that the cured film thickness became 15 μm, the composition was cured by heating at 80° C. for 30 minutes, Thus, a test panel with a coated film was prepared and evaluated.

[0256] The evaluation results are shown in Tables 2-4.

[0257] [Table 2]

[0258]

[0259] [table 3]

[0260]

[0261] [Table 4-1]

[0262] Table 4-1

[0263]

[0264] 1) SOLVESSO 100 / methyl isobutyl ketone = 9 / 1 (weight) 5) Mixed solvent of n-butyl acetate and methyl isobutyl ketone

[0265] 2) sec-butanol 6) isobutanol

[0266] 3) mixed solvent of toluene and n-butyl ace...

Embodiment A30~45 and comparative example A21~39

[0276] The composition is prepared by mixing titanium oxide dispersed polyol solution A1, melamine resin (B), Lewis acid catalyst (C) or other catalyst (c'), and solvent (D) at the ratios shown in Tables 5 to 7 (white coating material) and evaluated.

[0277] After the obtained composition was coated on a steel plate (150 mm x 70 mm x thickness 0.8 mm) using a bar coater so that the cured film thickness became 15 μm, the composition was cured by heating at 80° C. for 30 minutes, Thus, a test panel with a coated film was prepared and evaluated.

[0278] The evaluation results are shown in Tables 5-7.

[0279] [table 5]

[0280]

[0281] [Table 6-1]

[0282]

[0283] [Table 6-2]

[0284] Table 6-2

[0285]

[0286] 1) SOLVESSO 100 / methyl isobutyl ketone=9 / 1 (weight)

[0287] 2) Isobutanol

[0288] [Table 7]

[0289] Table 7

[0290]

[0291] 1) SOLVESSO 100 / methyl isobutyl ketone=9 / 1 (weight)

[0292] 2) Isobutanol

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com