Method for preparing superabsorbent polymer

A superabsorbent, polymer technology, applied in the field of superabsorbent polymer preparation, can solve the problems of deterioration of working environment, increase of process load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

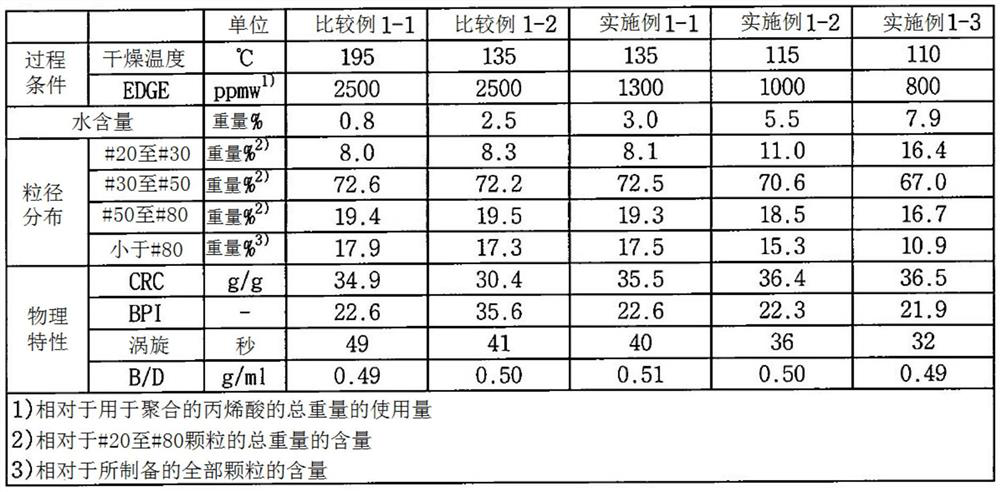

Embodiment 1-1

[0123] (step 1)

[0124] 609.8 g of NaOH (31.5% by weight) and 229.1 g of water were put into a double-jacketed glass reactor, and cooled to 20° C. while stirring with a magnetic stirrer to prepare solution A. 0.3 g of PEGDA solution (polyethylene glycol diacrylate, weight average molecular weight = 400, 2% by weight in AA (acrylic acid)), 18.8 g of phenylbis(2,4,6-trimethyl A solution of benzoyl)phosphine oxide (0.21% by weight in AA) and 474.9 g of AA (acrylic acid) were placed in a double-jacketed neutralization tank equipped with a forced vortex impeller and stirred at 300 rpm to prepare solution B. Solution A was mixed while filling solution A into the neutralization tank containing solution B using a pump. While circulating the refrigerant cooled to 20°C by the cooling circulator through the outer jacket of the double-jacketed reactor, the temperature of the neutralized solution raised to about 65°C due to the heat generated when AA and NaOH are neutralized Cool to 50°...

Embodiment 1-2

[0130] Prepared in the same manner as in Example 1-1, but in step 1 of Example 1-1, 4.9 g of EGDE solution (in H 2 10% by weight in O) and 24.7g SPS (sodium persulfate) solution (in H 2 4% by weight in O), and in step 2 of Example 1-1, the obtained chips were dried by hot air at 115° C. for 39 minutes, thereby preparing granules.

Embodiment 1-3

[0132] Prepare in the same manner as in Example 1-1, but in step 1 of Example 1-1, use 4.0 g of EGDE solution (in H 2 10% by weight in O) and 30.9g SPS (sodium persulfate) solution (in H 2 4% by weight in O), and in step 2 of Example 1-1, the obtained chips were dried by hot air at 100° C. for 39 minutes, thereby preparing granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com