Voice diaphragm material of loudspeaker and preparation method and application thereof

A loudspeaker and sound film technology, which is applied in the field of loudspeakers, can solve the problems of reducing mechanical properties, affecting the acoustic properties of the sound film, and poor waterproof and moisture-proof performance of the high-pitched sound film, so as to enhance waterproof and moisture-proof performance, reduce contact and adsorption, and enhance moisture-proof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

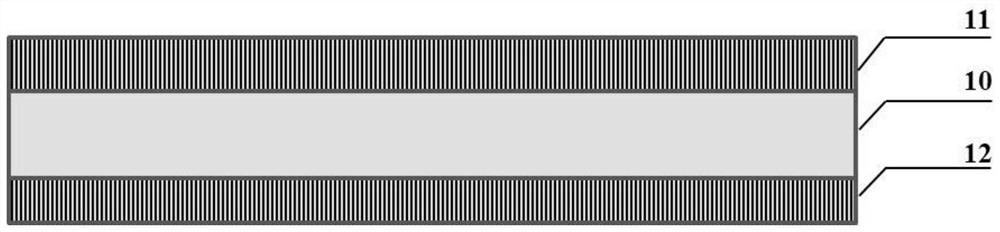

[0064] A kind of sound membrane material, comprises base material (silk cloth, weight is 85g / m 2 ) and the first moisture-proof layer and the second moisture-proof layer arranged on both surfaces of the base material, the schematic diagram of which is shown in figure 1 As shown, wherein, 10-substrate, 11-the first moisture-proof layer, 12-the second moisture-proof layer, the thickness of the first moisture-proof layer is 30 μm, and the thickness of the second moisture-proof layer is 10 μm; the material of the first moisture-proof layer includes: 48 parts by weight of acrylic polymer, 48 parts by weight of styrene-butadiene copolymer and 4 parts by weight of fluororesin, the material of the second moisture-proof layer includes: 49.5 parts by weight of acrylic polymer, styrene-butadiene copolymer 49.5 parts by weight and 1 part by weight of fluororesin; the preparation method is as follows:

[0065] (1) Mix 48 parts by weight of acrylic emulsion, 48 parts by weight of styrene-...

Embodiment 2

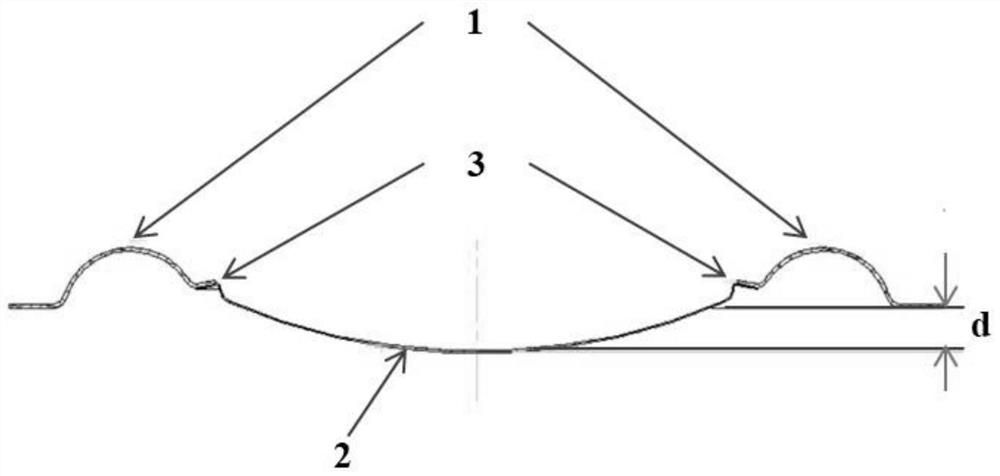

[0068] A kind of sound membrane material, comprises base material (silk cloth, weight is 85g / m 2 ) and the first moisture-proof layer and the second moisture-proof layer arranged on both surfaces of the base material, the schematic diagram of which is shown in figure 2 As shown, wherein, 10-substrate, 11-the first moisture-proof layer, 12-the second moisture-proof layer, the thickness of the first moisture-proof layer is 20 μm, and the thickness of the second moisture-proof layer is 20 μm; the material of the first moisture-proof layer includes: 48 parts by weight of acrylic polymer, 48 parts by weight of styrene-butadiene copolymer and 4 parts by weight of fluororesin, the material of the second moisture-proof layer includes: 49.5 parts by weight of acrylic polymer, styrene-butadiene copolymer 49.5 parts by weight and 1 part by weight of fluororesin; the preparation method is as follows:

[0069] (1) Mix 48 parts by weight of acrylic emulsion, 48 parts by weight of styrene-...

Embodiment 3

[0072] A kind of sound membrane material, comprises base material (silk cloth, weight is 85g / m 2 ) and the first moisture-proof layer and the second moisture-proof layer arranged on both surfaces of the base material, the schematic diagram of which is shown in figure 2 As shown, the thickness of the first moisture-proof layer is 20 μm, and the thickness of the second moisture-proof layer is 20 μm; the material of the first moisture-proof layer includes: 48 parts by weight of acrylic polymer, 47 parts by weight of styrene-butadiene copolymer and fluorine 5 parts by weight of resin, the material of the second moisture-proof layer includes: 50 parts by weight of acrylic polymer, 49 parts by weight of styrene-butadiene copolymer and 1 part by weight of fluororesin; the preparation method is as follows:

[0073] (1) Mix 48 parts by weight of acrylic emulsion, 47 parts by weight of styrene-butadiene latex and 5 parts by weight of water-based fluororesin to obtain the first moisture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com