Zirconium tetrafluoride-coated fluorine-aluminum double-doped lithium manganate positive electrode material and preparation method thereof

A positive electrode material, zirconium tetrafluoride technology, applied in chemical instruments and methods, positive electrodes, manganate/permanganate, etc., can solve the problem of first-time capacity reduction and poor rate performance of modified lithium manganate positive electrode active materials And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing the zirconium tetrafluoride-coated fluoroaluminum double-doped lithium manganate positive electrode material described in the above technical solution, comprising the following steps:

[0040] After mixing the manganese source, the lithium source, the aluminum source and the first fluorine source according to the stoichiometric ratio of the core, performing the first calcination to obtain the core;

[0041] Weighing the zirconium source and the second fluorine source according to the stoichiometric ratio as shell raw materials;

[0042] mixing the shell material with the core to form a cladding layer on the surface of the core to obtain a positive electrode material precursor;

[0043] The anode material precursor is subjected to the second calcination to obtain a fluorine-aluminum double-doped lithium manganate cathode material coated with zirconium tetrafluoride.

[0044] In the present invention, after mixin...

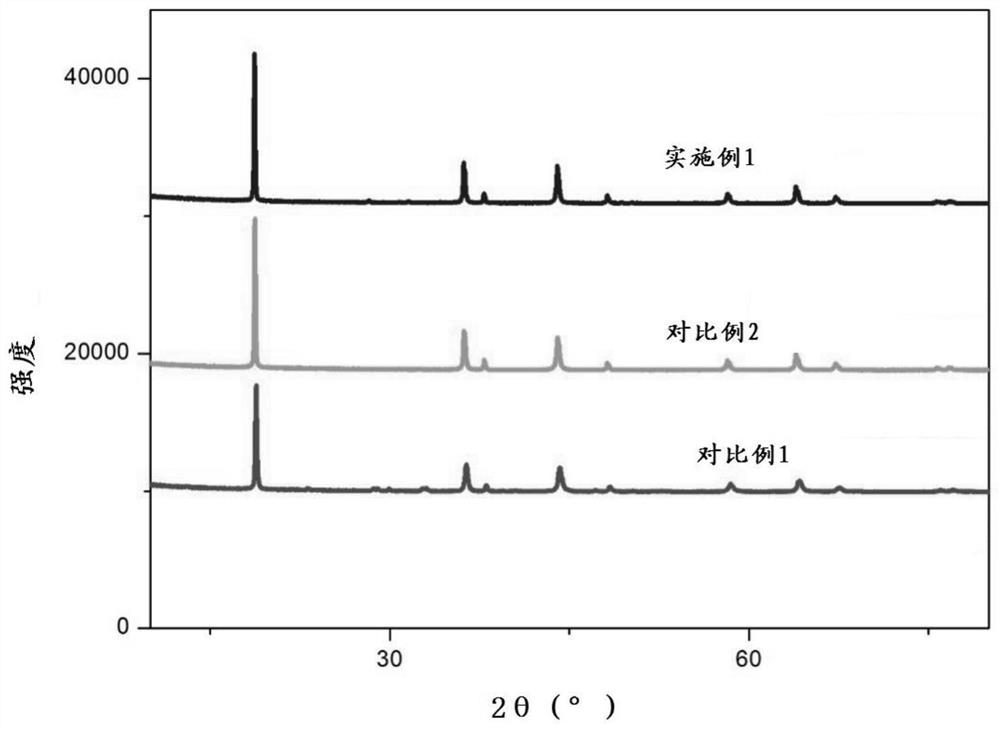

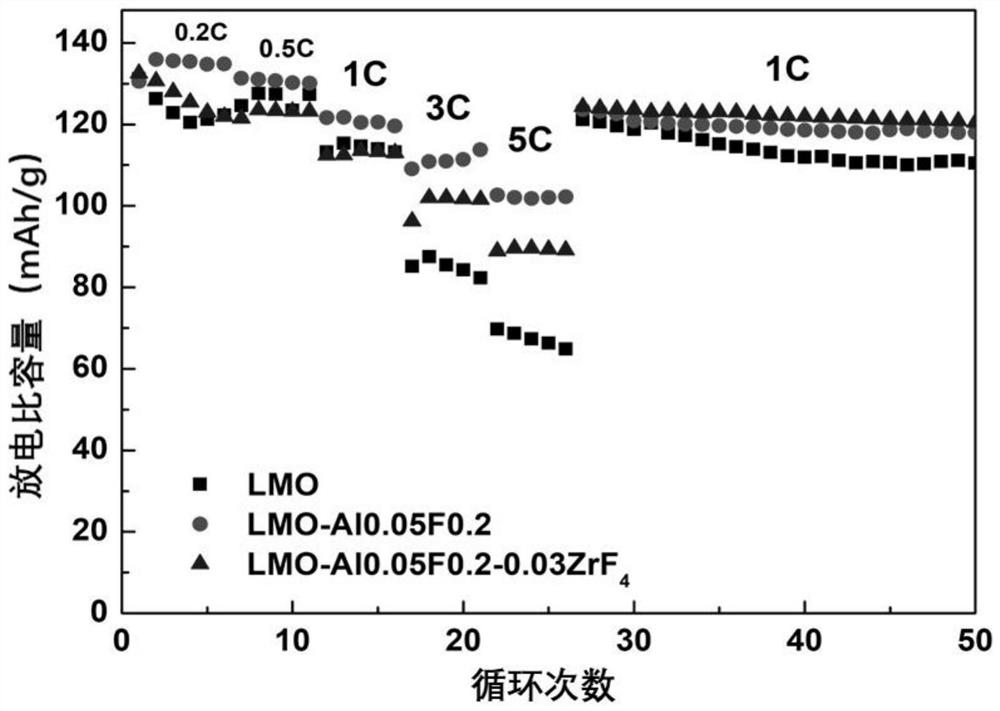

Embodiment 1

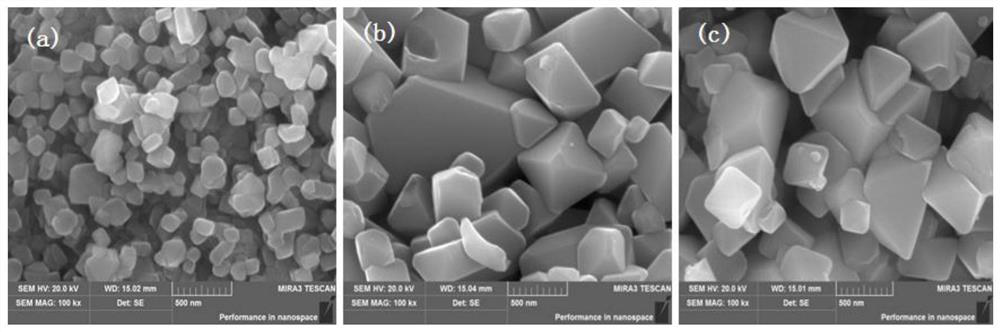

[0082] Preparation of ZrF 4 The mass percentage content is 3%, and the core is Li 1.02 Al 0.05 mn 1.95 o 3.95 f 0.05 The positive electrode material, its specific steps are as follows:

[0083] (1) Take by weighing 50g manganese dioxide in a 250mL ball mill jar, and ball mill it for 8h at a rotating speed of 105rpm, wherein the grinding balls used are zirconium balls with a diameter of 20mm and zirconium balls with a diameter of 8mm according to the mass ratio of 1: Mixed in a ratio of 1, the ratio of material to ball is 1:4; after the ball milling is completed, pass through a 200-mesh sieve to separate the grinding balls to obtain manganese dioxide with an average particle size of 6 μm;

[0084] 27.9451g of manganese dioxide with a particle size of 6 μm, 0.1965g of lithium fluoride, 0.6031g of aluminum hydroxide and 5.5994g of lithium carbonate were placed in a ball mill jar, and ball milled for 1 hour at a speed of 105rpm, wherein the grinding balls used were Zirconium...

Embodiment 2

[0088] Prepare ZrF according to the method for embodiment 1 4 The mass percentage content is 2%, and the core is Li 1.02 Al 0.05 mn 1.95 o 3.95 f 0.05 The positive electrode material, abbreviated as LMO-Al0.05F0.05@2%ZrF 4 , the difference is that the quality of zirconyl nitrate in step (2) is 0.1383g, and the quality of ammonium fluoride is 0.0885g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com