A high-stability support structure applied to a long space mirror

A technology of supporting structure and mirror, applied in the field of aerospace optical remote sensor, can solve the problem of instability of the supporting structure of the mirror, and achieve the effects of good environmental adaptability, strong practicability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

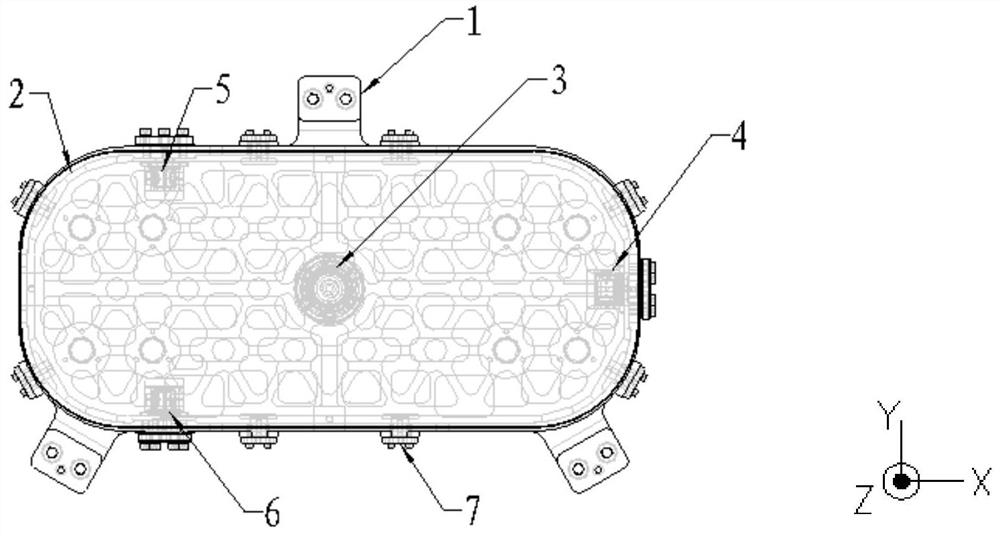

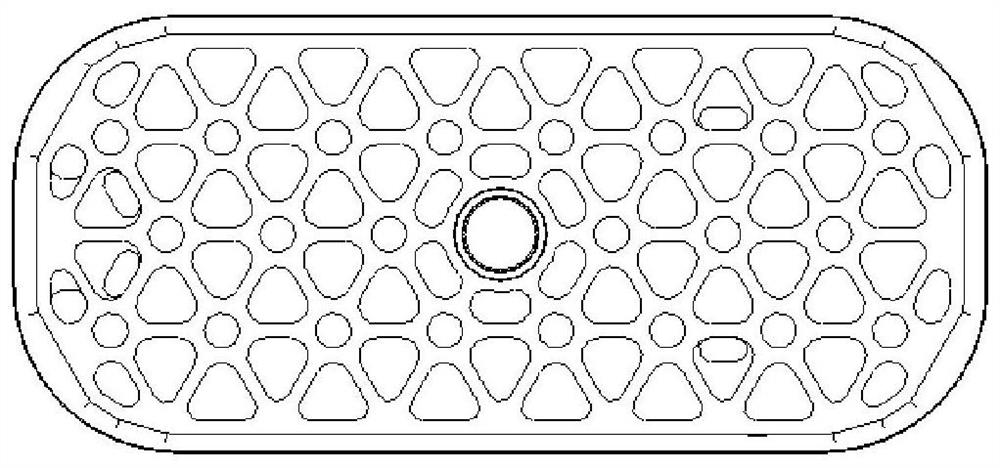

[0036] The reflector supported by the elongated reflector support structure in the present invention is an off-axis reflector with a diameter of 505mm×235mm and a working temperature of 20±2°C, including a mirror frame 1, a center support 3, a side support 4, an upper Support 5, lower support 6 and 8 auxiliary glue points 7, such as figure 1 shown.

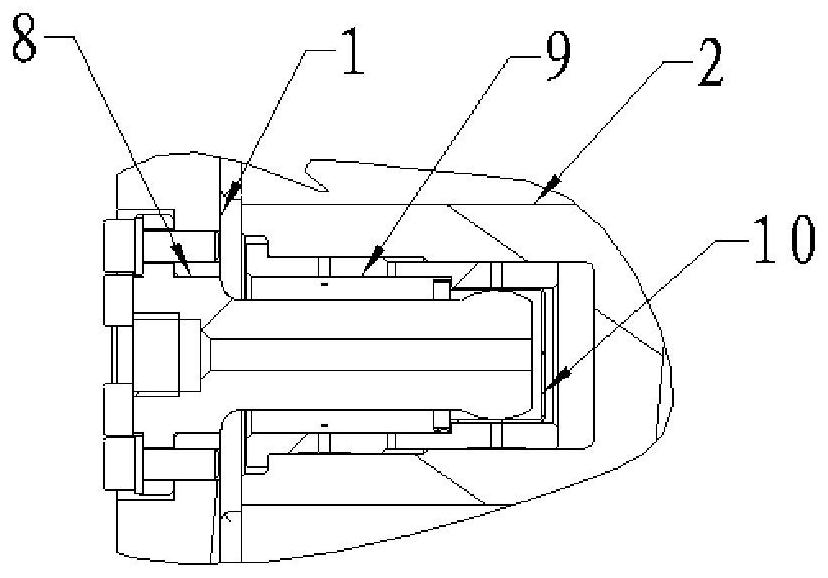

[0037] According to the principle of kinematics, the constraint of 6 degrees of freedom of the mirror is realized. The central support 3 is located in the center of the reflector 2, inserted from the back of the reflector 2 to play a supporting role, and the rest of the supports are inserted from the side of the reflector to play a support role.

[0038] The support point of the center support 3 coincides with the center of mass of the mirror 2, and its axis is parallel to the optical axis, so as to realize the constraint of the translation of the long axis direction and the short axis direction of the mirror 2; the side support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com