Multi-layer tunnel microwave drying sterilizer

A microwave drying and sterilization, tunnel-type technology, applied in the direction of dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of bacterial death, adjustment dysfunction, increase the operation process and the number of equipment, etc., to achieve convenient Cooling and stirring, and the effect of convenient discharge operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

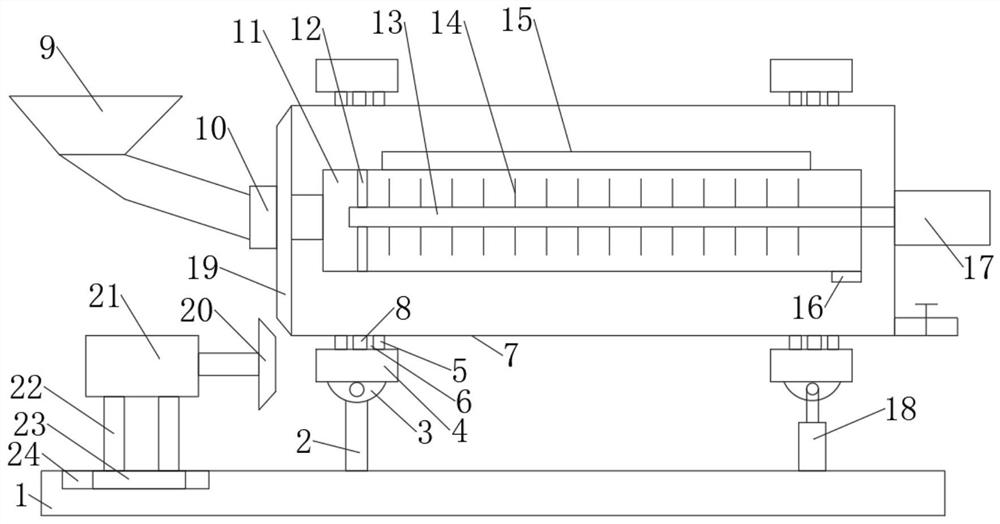

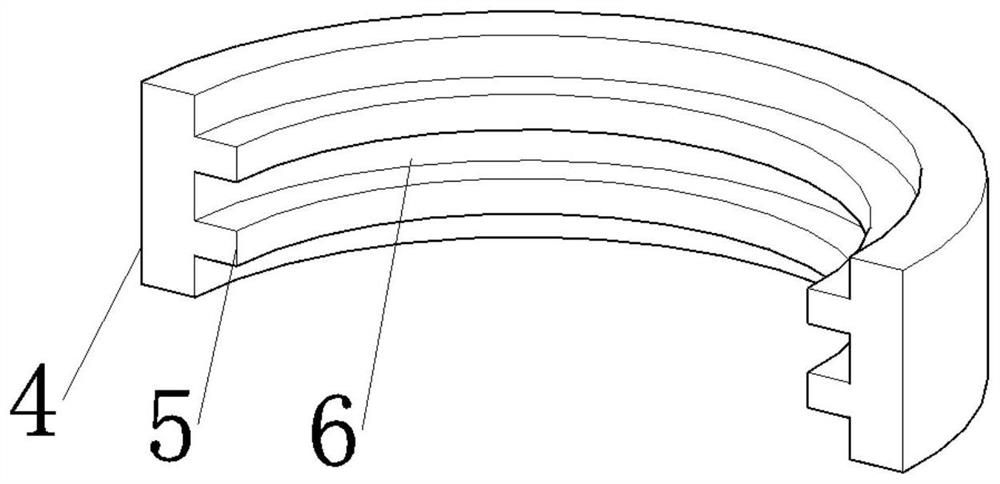

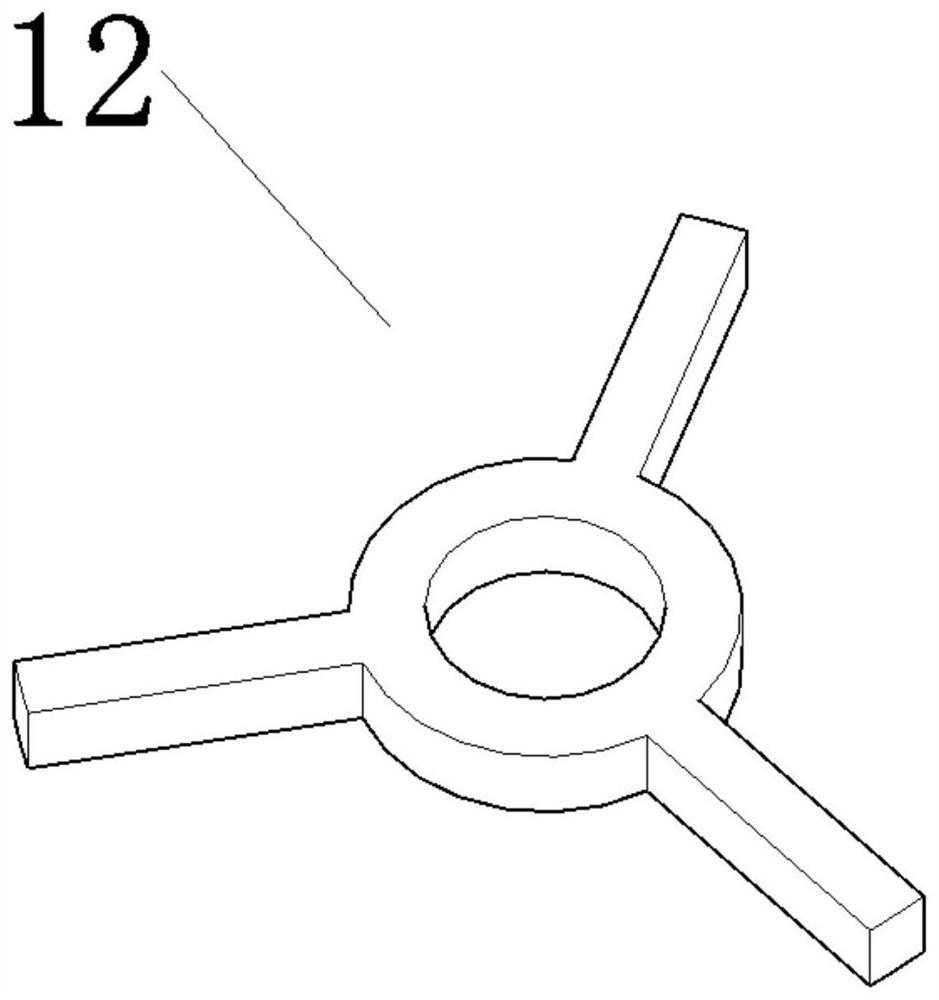

[0025] Such as Figure 1-4 As shown, the multi-layer tunnel type microwave drying and sterilizing machine includes a base 1, a support column 2 is arranged on the base 1, a cooling cylinder 7 is movably installed on the support column 2, and a stirring cylinder 7 is installed in the cooling cylinder 7. cylinder 11, the top of the mixing cylinder 11 is provided with a microwave generator 15, the inside of the mixing cylinder 11 is provided with a stirring device, the mixing cylinder 11 is fixedly connected with the cooling cylinder 7, and the bottom of the mixing cylinder 11 is provided with an outlet The feeding port 16, the mixing drum 11 and the end of the cooling drum 7 are connected with a feeding hopper 9, and the feeding hopper 9 is movably installed through the connecting sleeve 10 and the mixing drum 11.

[0026] Specifically, the cooling drum 7 is installed through the support column 2, and the mixing drum 11 is set in the installation drum, and the food raw materials...

Embodiment 2

[0038] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0039] Multi-layer tunnel microwave drying and sterilizing machine, including all parts in embodiment 1, also includes:

[0040] Further, the cooling cylinder 7 is installed in rotation with the support column 2, and the other end of the cooling cylinder 7 is connected to the base 1 through a hydraulic cylinder 18. The cooling cylinder 7 is provided with a feeding pipe, and the feeding The pipe is provided with a valve.

[0041]Specifically, in order to improve the stirring, drying and sterilizing effects of food raw materials, by installing one end of the cooling cylinder 7 on the hydraulic cylinder 18, it is convenient to control the overall rotation of the cooling cylinder 7, so that the food raw materials are in the mixing cylinder 11 and the cooling cylinder 7. Moving back and forth is convenient for the subsequent discharge operation of the cooling cylinder 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com