A gear-type fixed-point tilting pouring machine

A pouring machine and gear-type technology, applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of potential safety hazards, metal solution splashing, harsh environment, etc., to improve pouring quality and ensure that the position is not change and avoid emergencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

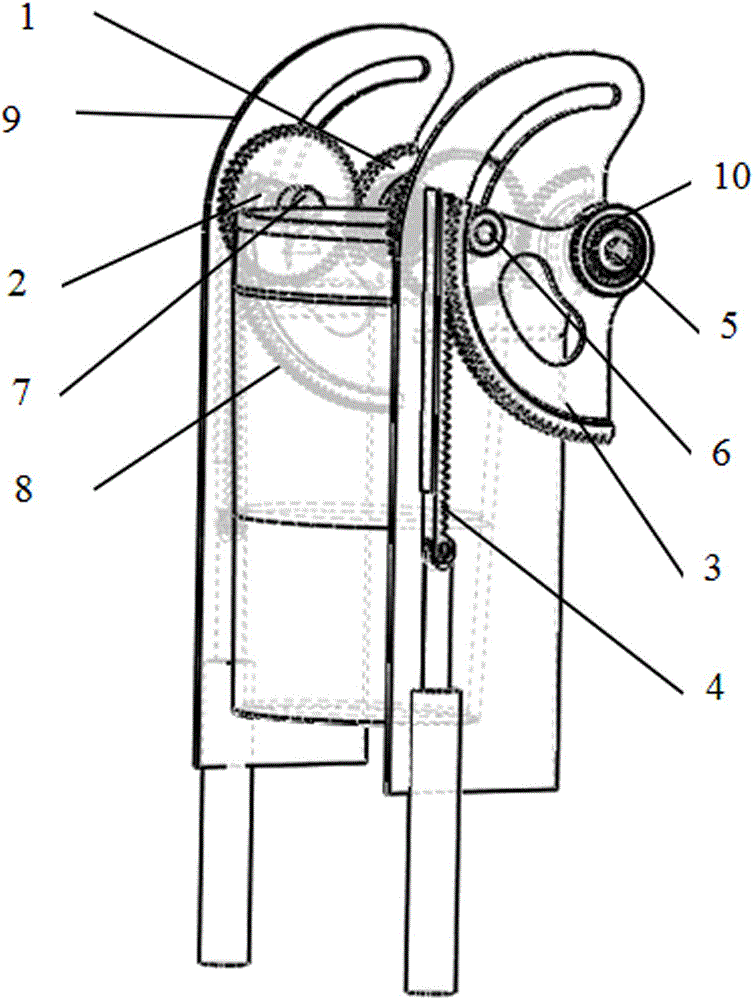

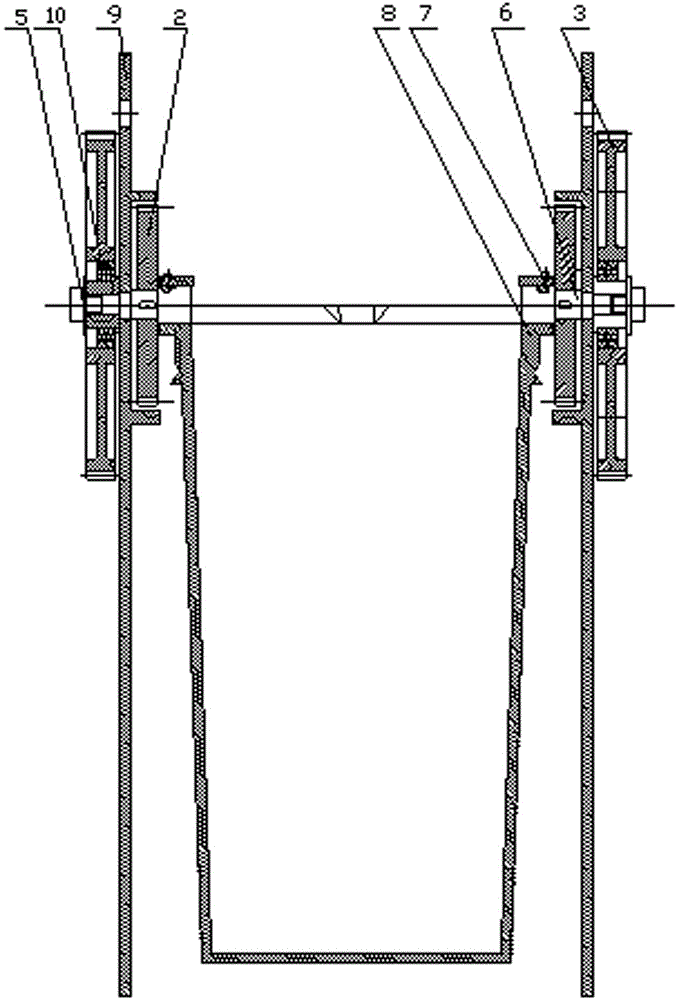

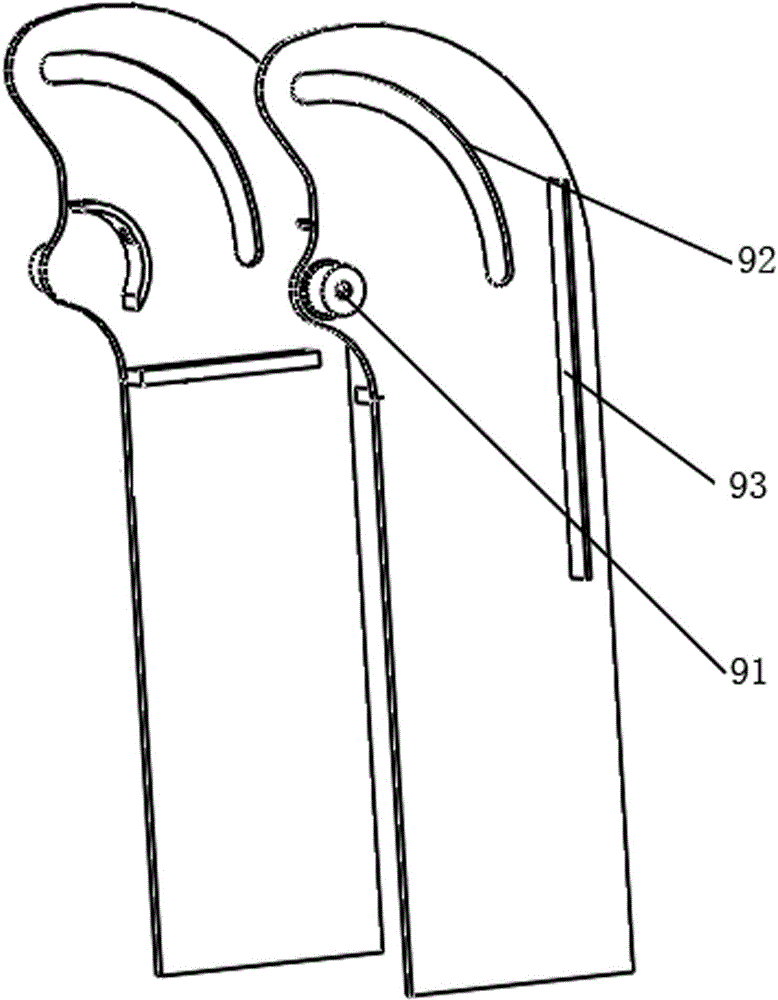

[0020] Such as Figure 1-4 As shown, the present invention includes two support plates 9 and ladles 8 arranged in parallel, and the opposite faces of the two support plates 9 are respectively provided with a cylindrical boss 91 and an arc-shaped groove centered on the center of the boss 91 92, a half-moon sun gear 1 is fixedly installed on the opposite surfaces of the two support plates 9, and the center of the sun gear 1 coincides with the center of the boss 91; a fan-shaped external gear 3 is installed on the boss 91 through a deep groove ball bearing 10 , between the outer gear 3 and the outer ring of the deep groove ball bearing 10 and between the inner ring of the deep groove ball bearing 10 and the boss 91 are interference fits, and the deep groove ball bearing 10 and the outer gear 3 are installed on the The bearing cover 5 at the end of the boss 91 is fixed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com