Frog assembly and turnout structure

A technology for components and frogs, applied in the directions of roads, tracks, switches, etc., can solve the problems of inconvenient transportation, difficult processing, and high processing costs, achieve convenient transportation, reduce casting and processing difficulties, and ensure frog performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

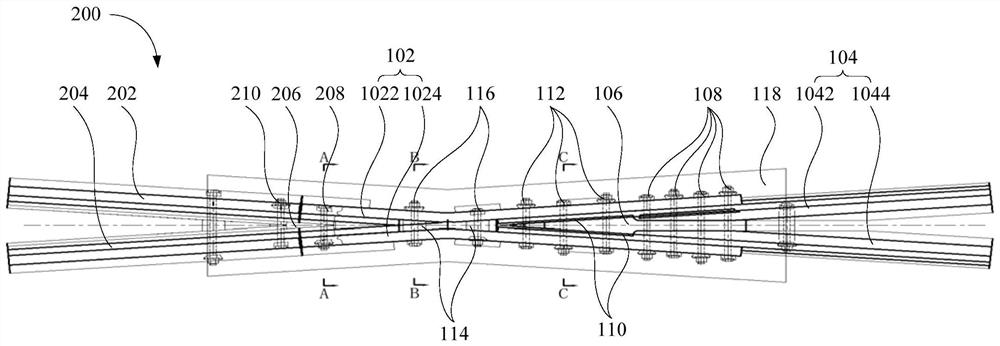

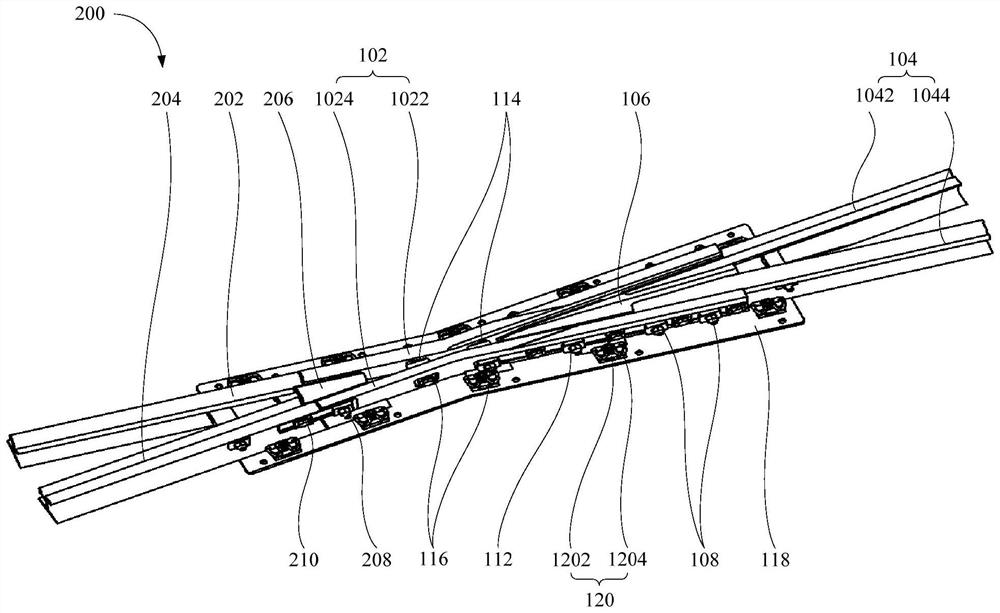

[0052] like figure 1 As shown, the present invention provides a frog assembly 100, comprising: a wing rail 102, a fork heel rail 104 and a core rail 106, wherein the wing rail 102 includes a first wing rail 1022 and a second wing rail 1024; 104 includes a first fork and heel rail 1042 and a second fork and heel rail 1044 .

[0053] Specifically, one end of the first fork heel rail 1042 is inserted at one end of the first wing rail 1022; one end of the second fork heel rail 1044 is inserted at one end of the second wing rail 1024; a core rail 106 is also included, which is arranged on the second wing rail 1024. The first wing rail 1022 and the second wing rail 1024 are located at the junction of the wing rail 102 and the fork heel rail 104 ;

[0054] The frog assembly 100 provided by the present invention includes a wing rail 102, a core rail 106, and a fork heel rail 104, wherein the wing rail 102 includes a first wing rail 1022 and a second wing rail 1024, and the fork heel ...

Embodiment 2

[0057] On the basis of the above examples, if figure 1 and Figure 4 As shown, the frog assembly 100 provided by the present invention may also include: a first spacer iron 110 disposed between the core rail 106 and the wing rail 102; the core rail 106, the wing rail 102 and the first spacer iron 110 pass through the second The connection part 112 is connected.

[0058] Specifically, a first spacer iron 110 is provided between the first wing rail 1022 and the core rail 106 and between the second wing rail 1024 and the core rail 106. Meanwhile, the first wing rail 1022 is connected to the , the second wing rail 1024 , the core rail 106 and the first spacer iron 110 are connected. Through the setting of the first spacer iron 110, when the train passes the frog assembly 100, the first spacer iron 110 acts as a buffer against the impact between the wing rail 102 and the core rail 106, preventing the core rail 106 and the wing rail 102 from Transitional wear improves the service...

Embodiment 3

[0061] On the basis of any of the above-mentioned embodiments, such as figure 1 and Figure 5 As shown, the frog assembly 100 provided by the present invention may also include: a second spacer iron 114 disposed between the first wing rail 1022 and the second wing rail 1024; the first wing rail 1022, the second wing rail 1024 and the second wing rail 1024 The two spacer irons 114 are connected by a third connecting portion 116 .

[0062] Specifically, the second spacer iron 114 is set between the first wing rail 1022 and the second wing rail 1024, so that the size of the second spacer iron 114 can be used to ensure the distance between the first wing rail 1022 and the second wing rail 1024. distance, so as to ensure the installation size of the frog assembly 100, thereby ensuring the stability of the frog assembly 100. Further, the second spacer iron 114 can be arranged at the throat of the first wing rail 1022 and the second wing rail 1024, that is, the minimum distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com