Graded gasification method and device

A gasification agent and coal gas technology, applied in the field of gasification, can solve the problems of the existence of fly ash, the reaction of the gasification agent, the complex system, etc., and achieve the effects of reducing waste water discharge, improving gasification performance, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

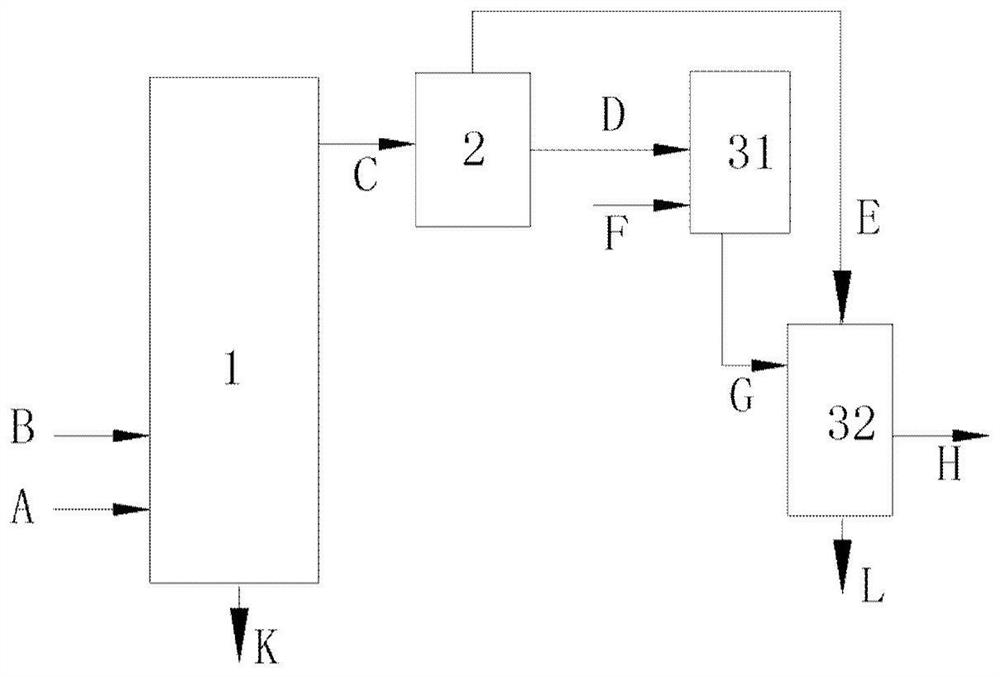

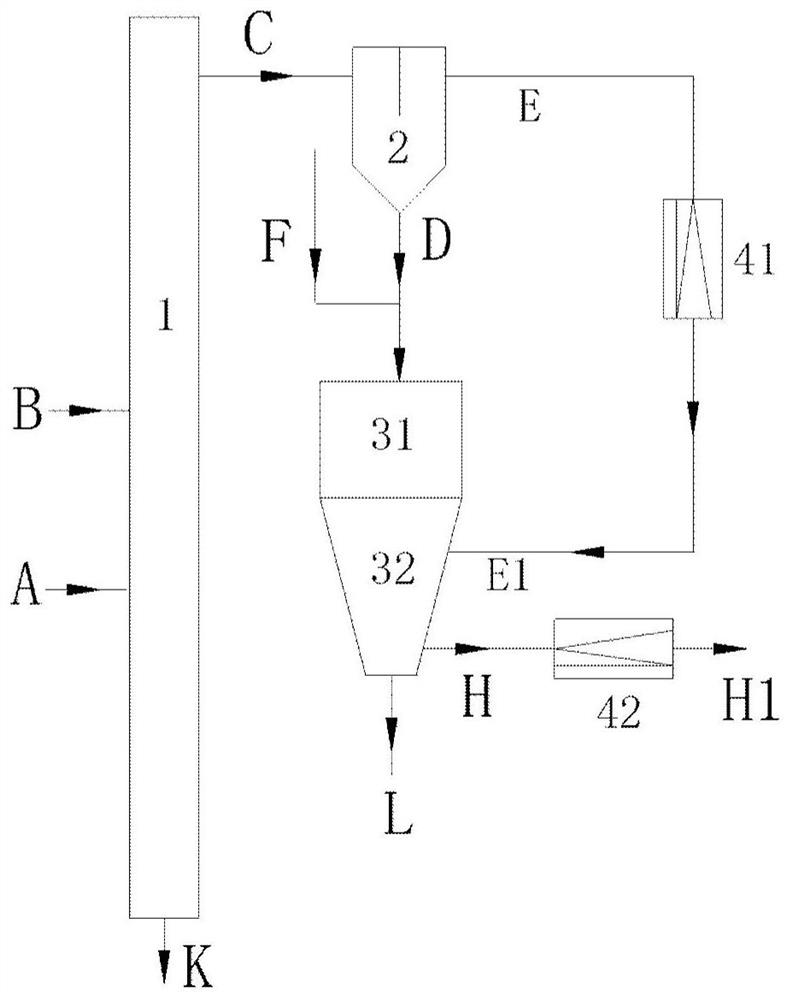

[0056] figure 2 It is a schematic structural diagram of the device adopted in the staged gasification method of this embodiment, and the method of this embodiment includes the following steps:

[0057] a) Pass the fuel B (take coal as an example) and the first gasification agent A respectively through the fuel inlet and the first gasification agent inlet into the primary gasification unit 1 for gasification reaction, and generate gas-solid mixture C and bottom slag K; wherein, the bottom slag K is discharged from the bottom slag outlet, and the gas-solid mixture C enters the separation unit 2 from the gas-solid mixture outlet and the separation unit inlet.

[0058] b) The gas-solid mixture C passes through the separation unit 2 to realize gas-solid separation, forming primary coal gas E and hot semi-coke D;

[0059] c) Send the hot semi-coke D and the second gasification agent F into the high-temperature reactor 31 (ie, the first reactor) from the hot semi-coke inlet and the...

Embodiment 2

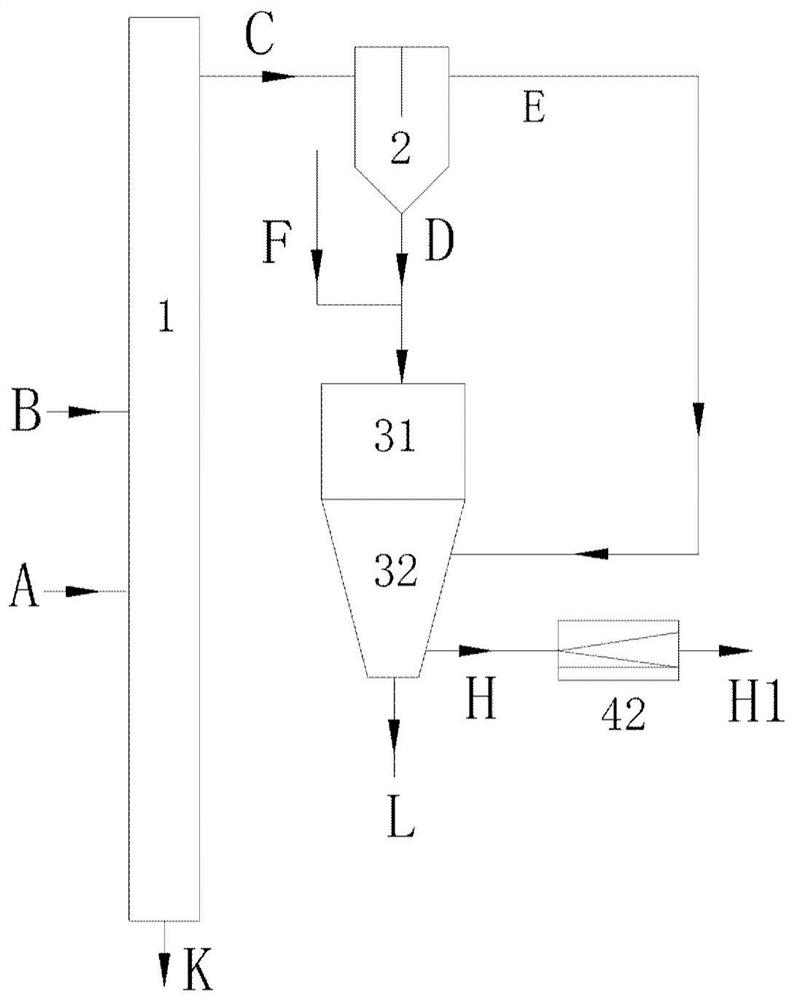

[0068] image 3 It is a schematic structural diagram of the device used in the staged gasification method of this embodiment. The difference between the method of this embodiment and embodiment 1 is:

[0069] The second gasifying agent F is a mixture of pure oxygen and water vapor.

[0070] Since the gasification agent is a mixture of pure oxygen and water vapor, at a certain temperature, the sensible heat of the high-temperature mixture G generated in the high-temperature reactor 31 is small, so that the primary coal gas E does not need heat exchange and cooling, and directly enters the heat exchanger. The thermal reactor 32 is mixed with the high-temperature mixture G to complete heat exchange and reaction, and the solid slagging of the heat exchange reactor 32 can be realized.

[0071] The first reactor and the heat exchange reactor have an integrated structure, that is, the outlet of the first reactor of the first reactor directly communicates with the first inlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com