Mixed refrigerant and air conditioning system

A technology for mixing refrigerants and air conditioning systems, used in transportation and packaging, air handling equipment, heating/cooling equipment, etc. Performance, the effect of low GWP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

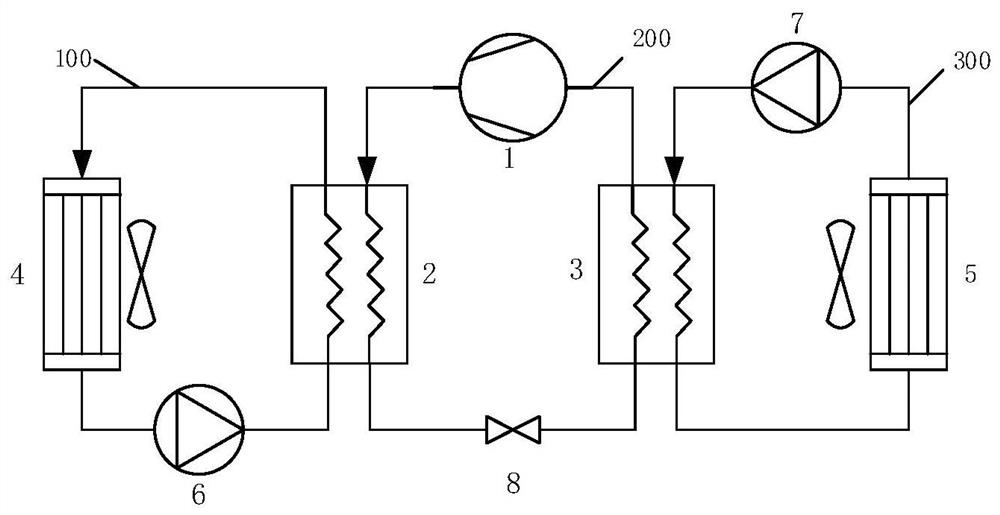

Method used

Image

Examples

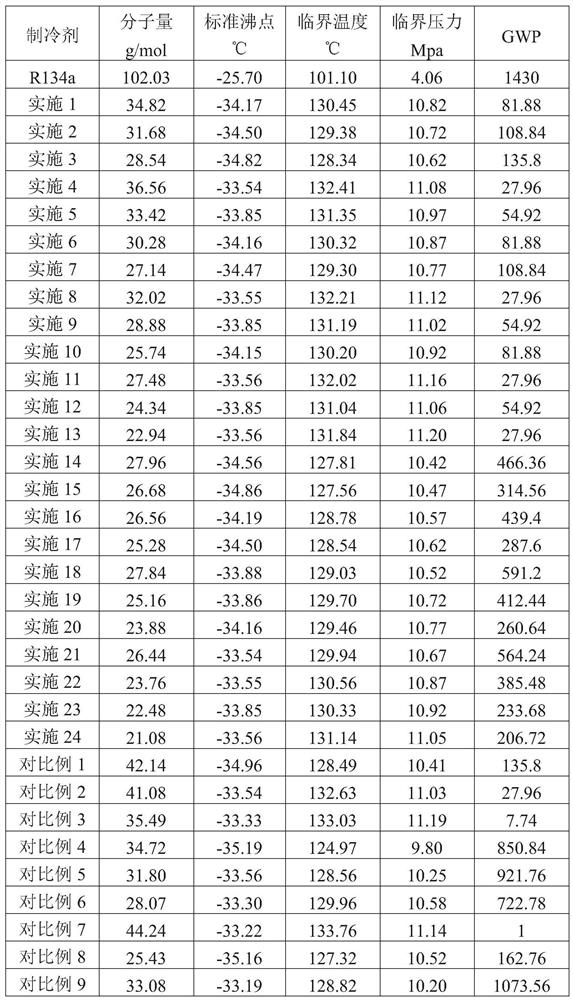

Embodiment 1

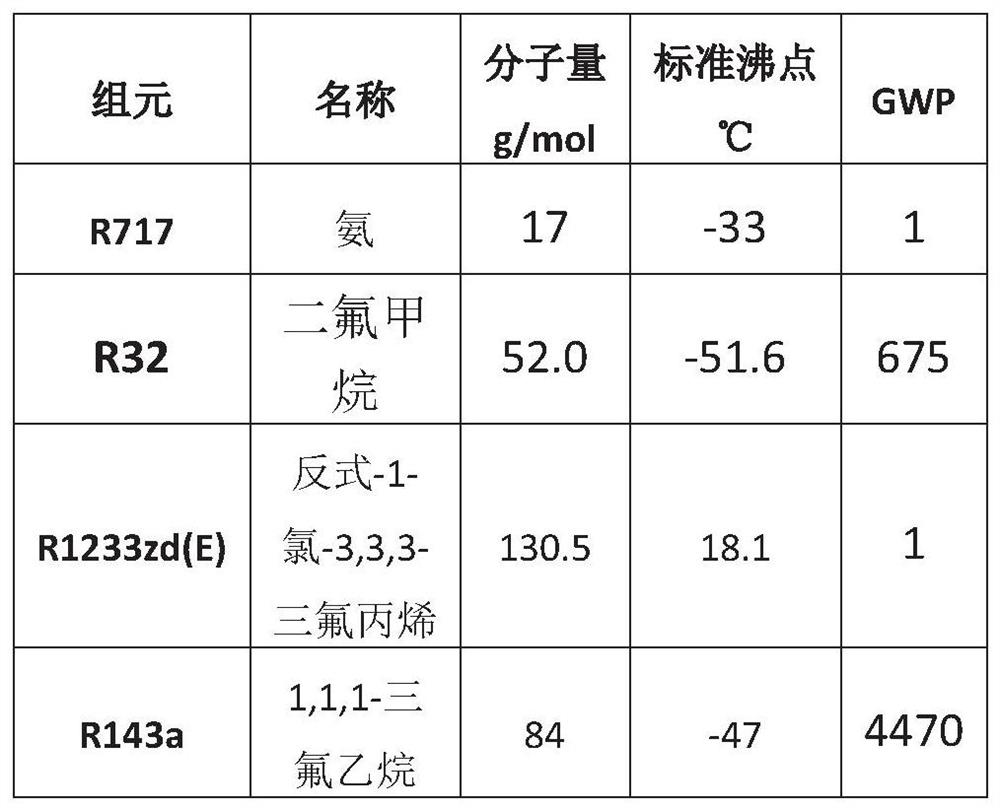

[0055] Example 1, the three components of ammonia (R717), difluoromethane (R32), and trans-1-chloro-3,3,3-trifluoropropene (R1233zd(E)) were prepared according to the The mass ratio of 76:12:12 is physically mixed to obtain an environmentally friendly mixed working fluid.

[0056] That is, in the state of liquid phase at normal temperature and pressure, the ammonia (R717), the difluoromethane (R32) and the trans-1-chloro-3,3,3-trifluoropropene (R1233zd(E) ) in a mass ratio of 76:12:12.

Embodiment 2

[0057] Example 2, the three components of ammonia (R717), difluoromethane (R32), and trans-1-chloro-3,3,3-trifluoropropene (R1233zd(E)) are prepared according to the The mass ratio of 76:16:8 is physically mixed to obtain an environmentally friendly mixed working fluid.

[0058] That is, in the state of liquid phase at normal temperature and pressure, the ammonia (R717), the difluoromethane (R32) and the trans-1-chloro-3,3,3-trifluoropropene (R1233zd(E) ) The mass ratio is 76:16:8.

Embodiment 3

[0059] Example 3, the three components of ammonia (R717), difluoromethane (R32), and trans-1-chloro-3,3,3-trifluoropropene (R1233zd(E)) were prepared according to the The mass ratio of 76:20:4 is physically mixed to obtain an environmentally friendly mixed working fluid.

[0060] That is, in the state of liquid phase at normal temperature and pressure, the ammonia (R717), the difluoromethane (R32) and the trans-1-chloro-3,3,3-trifluoropropene (R1233zd(E) ) The mass ratio is 76:20:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com