PS-b-P4VP copolymer film and preparation method thereof

A ps-b-p4vp, copolymer technology, applied in the direction of electrophoretic plating, coating, electrolytic coating, etc., to achieve the effect of good monodispersity, accelerated polymerization reaction, and uniform potential distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

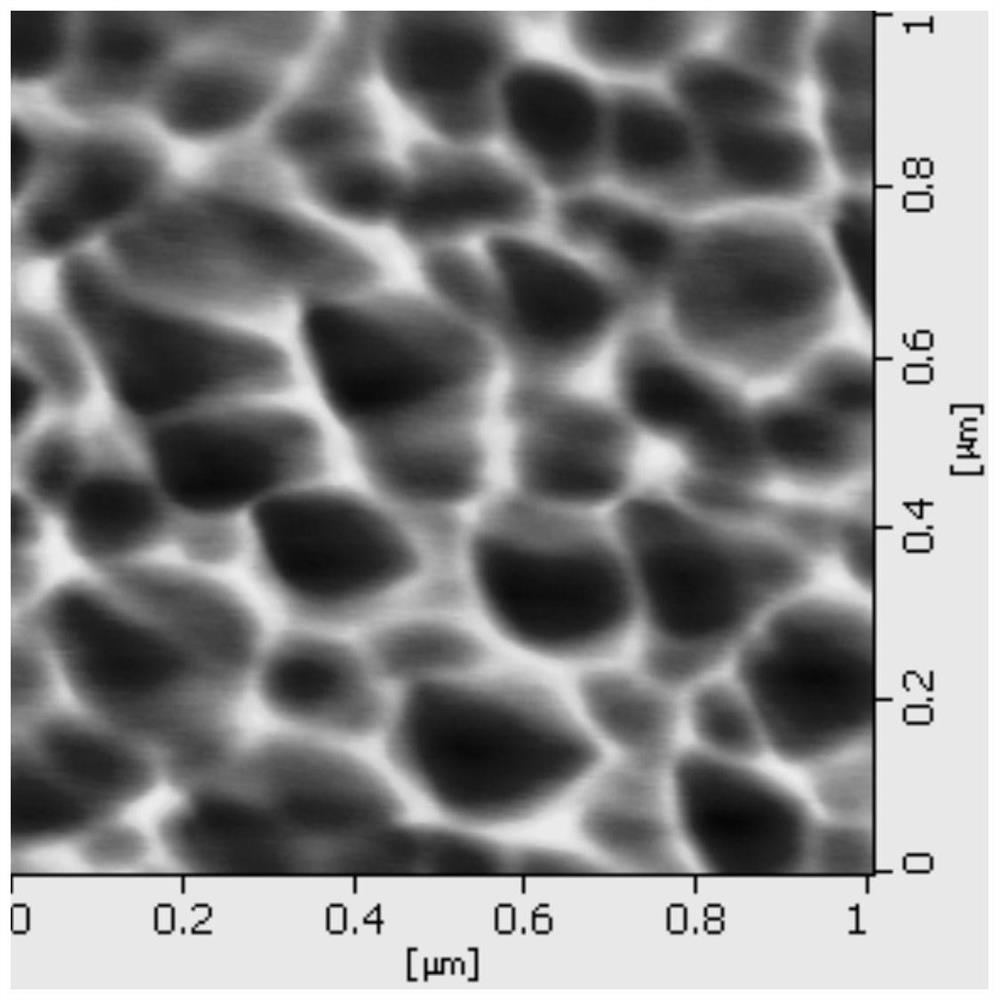

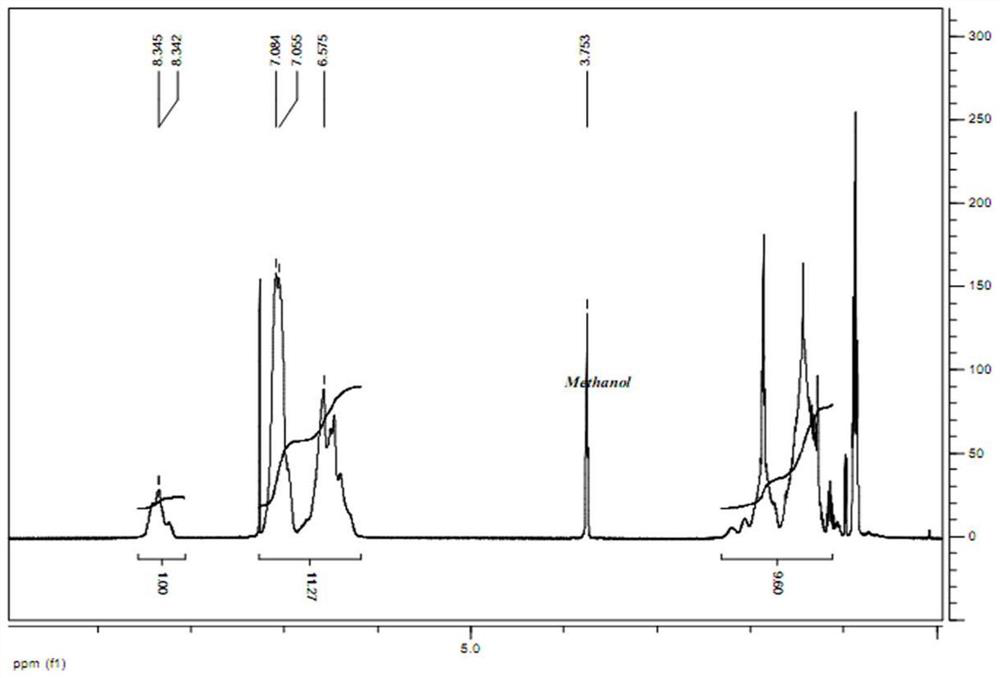

Image

Examples

Embodiment 1

[0025] A method for electrochemically preparing PS-b-P4VP copolymer film, comprising the following steps:

[0026] S1: Add polyvinyl alcohol to absolute ethanol to form solution A with a concentration of 45g / L; uniformly mix azobisisobutyronitrile and styrene at a mass ratio of 1:100 to obtain solution B; Mixed with solution B to obtain mixed solution C, the volume fraction of styrene in mixed solution C is 30%; under the protection of nitrogen, the solution C is heated to 70 ° C, and the reaction is stirred at a rate of 200rmp for 7h to obtain a polystyrene precursor ; Then the polystyrene precursor is formulated into a 50wt% emulsion;

[0027] S2: Immerse the ITO conductive glass sheet in the electrochemical workstation vertically into the polystyrene emulsion, take it out after 2 minutes and put it vertically into the constant temperature and humidity chamber. Take it out for later use;

[0028] S3: Uniformly mix sodium 120,000 sulfonate and deionized water at a solid-liq...

Embodiment 2

[0032] A method for electrochemically preparing PS-b-P4VP copolymer film, comprising the following steps:

[0033] S1: Add polyvinyl alcohol to absolute ethanol to configure solution A with a concentration of 40g / L; uniformly mix azobisisobutyronitrile and styrene at a mass ratio of 3:100 to obtain solution B; Mixed with solution B to obtain mixed solution C, the volume fraction of styrene in mixed solution C is 30%; under the protection of nitrogen, the solution C is heated to 70 ° C, and the reaction is stirred at a rate of 200rmp for 6h to obtain a polystyrene precursor ; Then the polystyrene precursor is formulated into a 45wt% emulsion;

[0034] S2: Immerse the ITO conductive glass sheet in the electrochemical workstation vertically into the polystyrene emulsion, take it out after 2 minutes and put it vertically into the constant temperature and humidity chamber. The temperature of the constant temperature and humidity chamber is controlled at 40°C and the relative humidi...

Embodiment 3

[0039] A method for electrochemically preparing PS-b-P4VP copolymer film, comprising the following steps:

[0040] S1: Add polyvinyl alcohol to absolute ethanol, and configure solution A with a concentration of 50g / L; azobisisobutyronitrile and styrene are uniformly mixed in a mass ratio of 5:100 to obtain solution B; solution A Mixed with solution B to obtain mixed solution C, the volume fraction of styrene in mixed solution C is 30%; under the protection of nitrogen, the solution C is heated to 70°C, and stirred at a rate of 200rmp for 8h to obtain a polystyrene precursor ; Then the polystyrene precursor is formulated into a 60wt% emulsion;

[0041] S2: Immerse the ITO conductive glass sheet in the electrochemical workstation vertically into the polystyrene emulsion, take it out after 1 min and put it vertically into the constant temperature and humidity chamber. After h, take it out for use;

[0042] S3: uniformly mix sodium lakhyl sulfonate and deionized water at a solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com