Low-frequency single hollow sound-insulation composite glass

A composite glass and glass technology, applied in the field of building sound insulation materials, can solve the problems of poor safety and durability, low production efficiency, and no problems, and achieve the effects of isolating low-frequency traffic noise, strengthening engineering versatility, and enhancing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

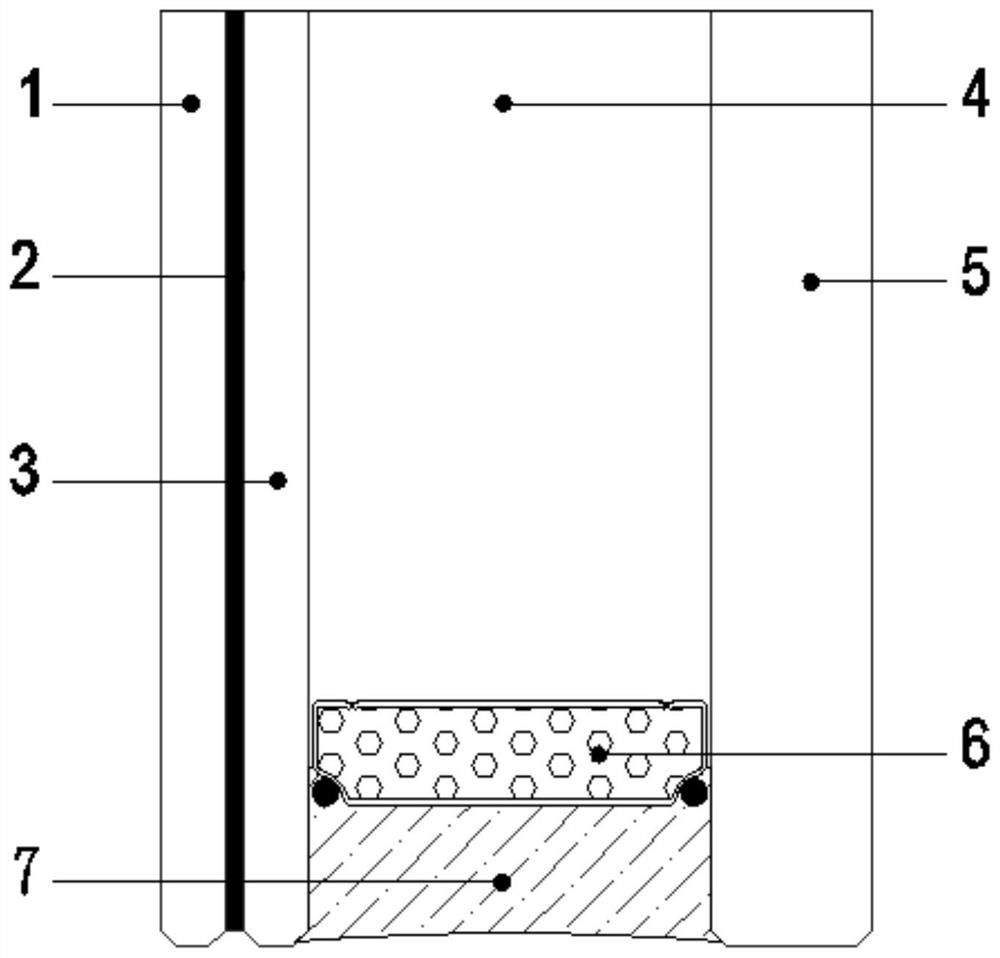

Image

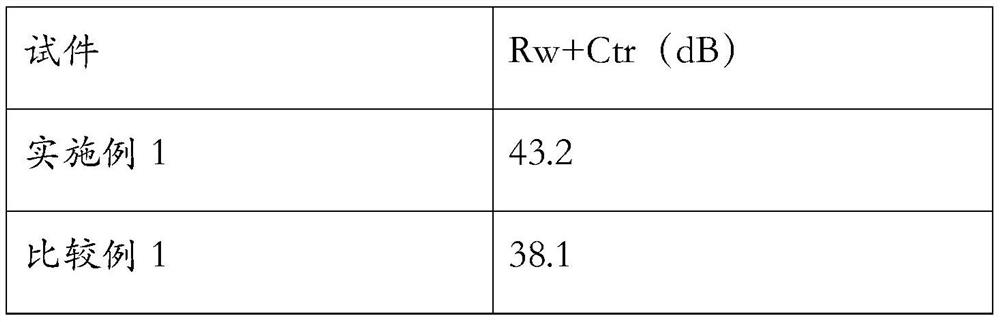

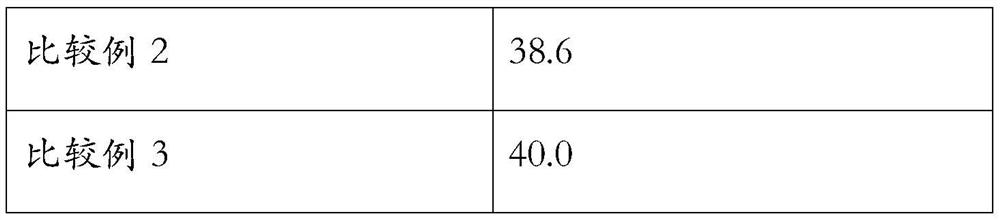

Examples

Embodiment 1

[0067] SiO 2 Airgel raw materials come from Zhejiang Shaoxing Nano Hi-Tech Co., Ltd. Its average pore diameter is 30nm; porosity is 90%; specific surface area is 800m 2 / g; Density 0.040g / cm 3 ; Thermal conductivity 0.015W / (m.k). Prepare the modified SiO according to the aforementioned method of the present invention 2 airgel.

[0068] Then prepare the raw materials for the two outer layers and the middle layer of the three-layer composite film respectively. The former raw material includes the PVB resin of 100 parts by weight, the dipropylene glycol dibenzoate of 35 parts by weight, the UV-9 of antioxidant 1010 and 3 parts by weight of 5 parts by weight; The latter raw material includes the PVB resin of 100 parts by weight, 35 parts by weight The modified SiO of the dipropylene glycol dibenzoate of weight part, 8 weight parts 2 Airgel, 5 parts by weight of antioxidant 1010 and 3 parts by weight of UV-9.

[0069] Wherein, among the above raw materials, the average molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com