In-place non-contact detection method for shaft type workpiece

A technology for shaft workpieces and detection methods, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problem that the machining accuracy of camshaft journal runout is very high, and cannot adapt to high-precision and high-efficiency large-scale production models. Problems such as low measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

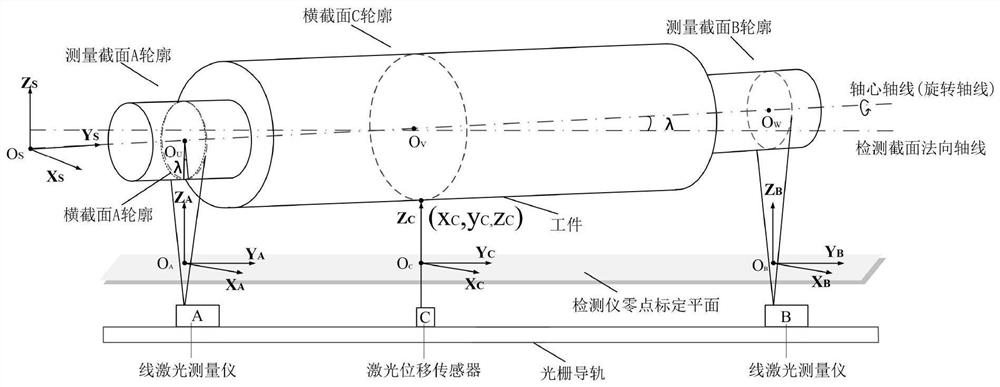

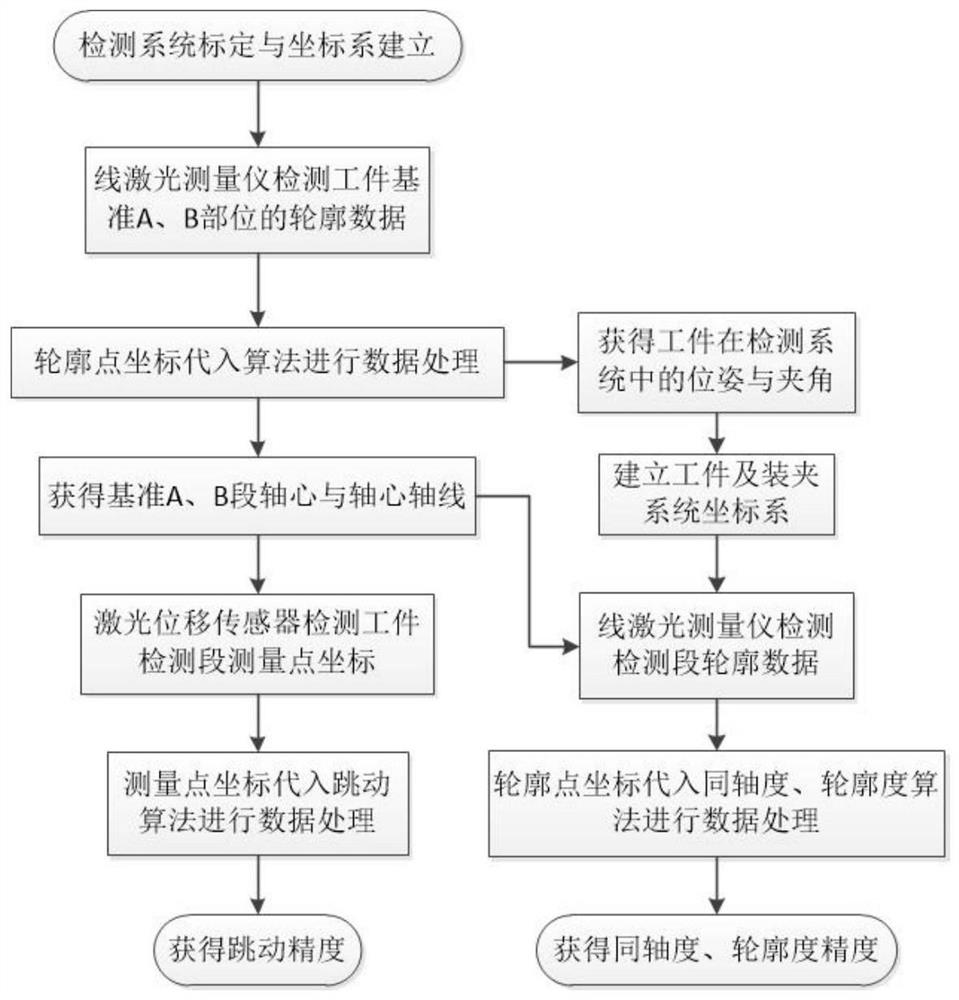

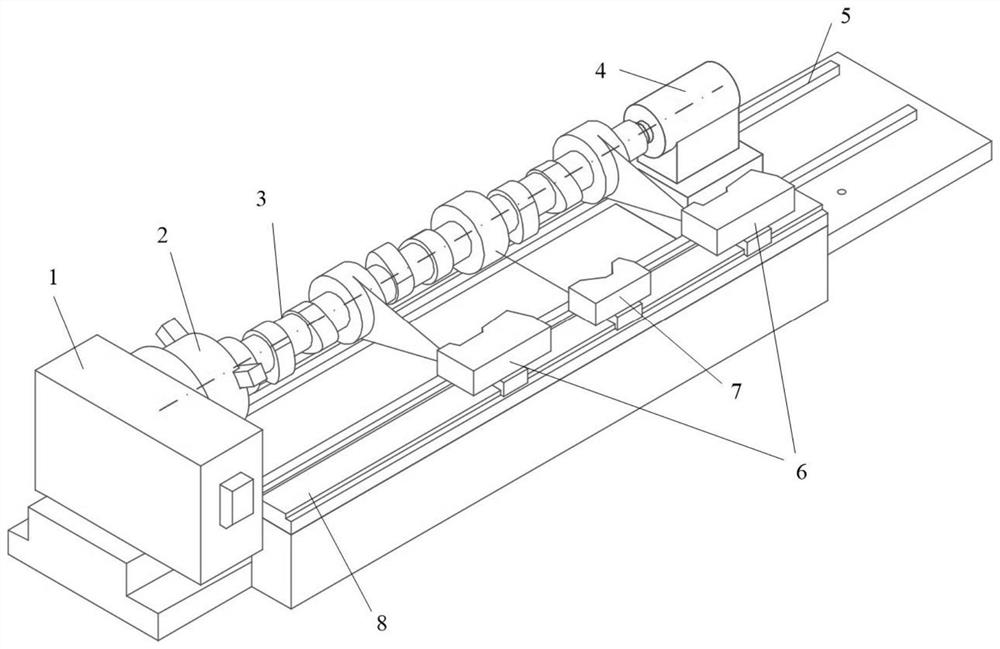

[0256] Taking the camshaft produced by a diesel engine factory as an example, the diameter of the camshaft journal is 180mm, the length is 1780mm, the runout tolerance requirement is 0.05mm, the coaxiality tolerance requirement is 0.05mm, and the camshaft profile requirement is 0.08mm. Therefore, according to the size of the camshaft to be detected, the line laser measuring instrument of the detection device selects a certain LJ-X8400 type, which can measure a maximum width of 320mm and has a precision of 5um; the CCD laser displacement sensor selects a certain LK-G400 type, with a precision of 2um and a measurable range of 400±100mm .

[0257] Place the detection system on one side of the machine tool, place the camshaft in the workpiece clamping device calibrated with the detection system above, align the optical path of the line laser measuring instrument with the reference axis section of the workpiece, and start the line laser measurement of positions A and B measuring in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com