Hydraulic brake motor device

A technology of hydraulic braking and braking devices, which is applied in the field of hydraulic braking motors and cycloidal hydraulic motors, can solve the problems of large structural radial size, complicated manufacturing process, and reduced product reliability, and achieve reliable braking structure The effect of compactness, simple and reliable processing technology, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

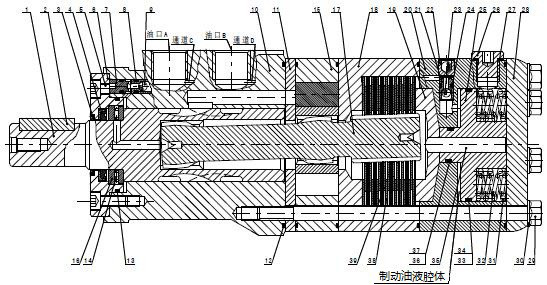

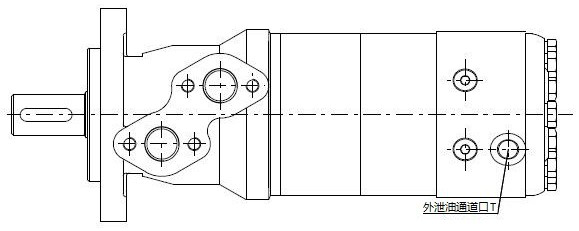

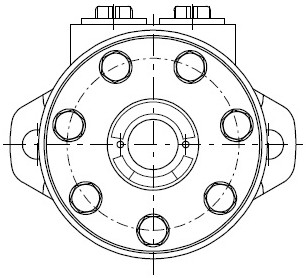

[0019] A schematic structural diagram of a hydraulic brake motor device in this embodiment is as follows: figure 1 As shown, the motor device is composed of a motor positioning and installation driving part, a motor main body engaging pair part and a motor braking device part, the motor positioning installing driving part includes parts between the output shaft 1 and the retaining ring 15, and the motor main body engaging pair part includes Rotating the stator pair 16 and the linkage shaft 17, the motor braking device part includes the parts between the brake seat 18 and the steel sheet 39.

[0020] The inside of the motor device has a structure that releases the function of the shuttle valve of the brake device. This structure is composed of two independent one-way valve functional parts, which communicate with the brake fluid cavity respectively. At the same time, the two independent one-way valve functions The components communicate with oil port A and oil port B of the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com